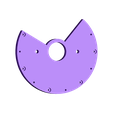

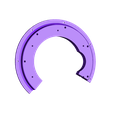

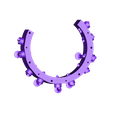

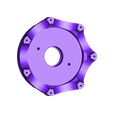

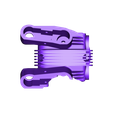

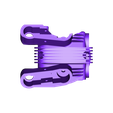

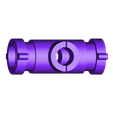

This is a model of the Radial Engine with 7-cylinder for old aircraft.

But, this type of engine includes many fundamental mechanisms.

This would be the optimal teaching material for the beginners' class engineers and students.

A. Features of this model are;

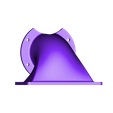

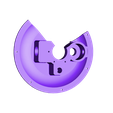

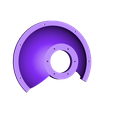

1. Cutaway model of entire engine;

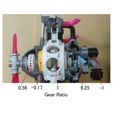

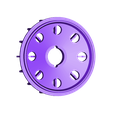

①. Reduction Gears (Planetary)

②. Cam and Drive gears

③. Crankshaft and Rod assembly

④. Cylinder and Piston with Valve mechanism

⑤. Supercharger gears and Impeller

2. Air Intake and Exhaust Pipes

3. Simplified Accessories (Propeller Hub with half blades, Carburetor, Magneto and Starter etc.)

4. It can be rotational but not smoothly because of the valve mechanism resistance and friction.

Refer to: https://youtu.be/uaWTmbg4mlE

B. Print and parts information

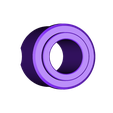

There are approximately 80 stl parts and many hardware including the bearings.

Hardware can be purchased from DIY shop or WEB shop easily and can be changed to equivalent similar parts.

All parts data are included in the manual. Refer Numerical Index.

It takes very long hours to print parts, treatment after printing and assembling.

STL file name: "ws" of last 2 digits means "With Support" which special designed.

But some parts need additional slicer's support to these. Refer “Remarks” column.

Estimated net print hour will be more than 90 hours.

C. Assembly manual (.pdf format in Zip)

The detail assembly manual including "Parts-List", "After printing treatment" and "Assembly procedure" are prepared.

But there are many complicated parts which required finishing and machining (Filing, Drilling and Tapping).

Also there are many fits required adjustment of clearance and tightening using with many hardware.

Some sample manual pages are shown in photos.

This manual can be very helpful for disassembly and re-assembly just like overhaul.

D. General Notes

1. For M1.4 Screw: No need "Tapping". Drill with φ1.0 drill then direct screw-in.

2. Screw to AL pipe: Put in a screw into the pipe end, squeeze pipe by the plier. Check the fixed condition.

3. Small diameter shaft parts:

To keep the strength, Use "100% infill" at printing and apply the adhesive for acrylic resin.

4. Recommended Drills and Taps

Drill: 1.0, 1.5, 2.0, 2.5, 3.0, 3.2, 5.0, 5.2, 7.2

Tap: M2, M3

3D printing settings

Raft, Support, Layer Height, Infill: Depending on your experience.

But the parts having gear, small shaft and thin portion: 100% infill is recommended.

My models were printed by "idbox" using with 0.4 nozzle, 1.75 PLA.

Before "Down-Loading", please watch photos carefully and consider deeply.

I do hope your success!!

[Updated 2017.10.10]

YouTube Video changed to longer version.

[Updated 2017.10.16]

A typo was corrected on photo.

[Updated 2018.2.10]

"Assembly Manual" typo and hardware qty, etc. corrected.

"Revision Record" page is added as Page 28.

[Updated 2018.10.29]

"Assembly Manual" typo corrected.

[Updated 2020.11.27] Optional Kits

https://cults3d.com/en/3d-model/tool/radial-engine-7-cylinder-optional-parts-kit

https://cults3d.com/en/3d-model/tool/radial-engine-7-cylinder-optional-parts-kit-2

[Update 2021.7.17]

Photo & Image size and format changed

[Update 2022.10.7] Optional Kit

https://cults3d.com/en/3d-model/tool/radial-engine-7-cylinder-optional-parts-kit-3-to-14-cylinder

[Update 2025.08.10]

Added iamge titled "[Radial Engine, 7-Cylinders, Cutway] Parts (except STL parts)"

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/122612b8-a666-49df-abdf-abef1c0b6875/Assy-01.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/d5dba3a8-f1c1-4e84-b69f-78e24a3149c2/Engine-000.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/30bc66e0-fcc7-4c0b-92d5-c78c638ccc63/P0-Engine-Assy.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/4ad1790b-a3ee-4e58-bb30-5c759f5c1a06/P0-Engine-Assy01.JPG)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/42e2b085-0a45-44bc-af95-fbe9c5b44518/00-MRH-Head-Stand-Assy01.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/689dafbf-c022-4d99-92f6-de60ca8b521d/05-Final-Assy01.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/b26fb69d-61e6-45a5-92c3-156b1048f2b7/VN-Link-Assy01.gif)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/c5962b96-554a-4f45-ba5e-e7bbd5a3732e/00-3BSN-Phase1.gif)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/7309d894-346d-4374-ba2a-71c1c314554e/00-Engine-Assy04.jpg)