This is the Mk Ultra. A high performance belt driven 4WD 1/10 scale buggy. It is very sophisticated and capable. The car can withstand plenty of abuse, and is easy to repair and maintain.

You can ask questions and read about the car development here:

https://www.rcgroups.com/forums/showthread.php?2952626-MKUltra-A-3D-Printable-4WD-1-10-scale-buggy

Here's a good source of hardware like bearings and fasteners for the car in one place:

https://rcprinter.com/products/mkultra-build-kits

Here's a great video by Elias F showing how he assembled his MK Ultra and even adapted some of his hardware to fit: https://www.youtube.com/watch?v=5rRw8LsLaLM

More videos:

https://youtu.be/KmVKcAIOOPk

https://www.youtube.com/watch?v=1nWqq_2L4IA

https://youtu.be/aaE_N88hye8

https://youtu.be/YBmmWoxyvKM

https://youtu.be/4D7m5fsxQ9I

Driving during development:

https://youtu.be/OO4_NmBveJM

How to install and remove the body:

https://youtu.be/kis6NHcgPJY

Free option parts:

https://cults3d.com/en/various/oil-shocks-for-1-10-scale-rc-cars

https://cults3d.com/en/various/cooling-fan-spur-gear-option-part-for-mkultra-1-10-4wd-buggy

https://cults3d.com/en/various/glueless-1-10-rc-car-wheels

The prototype runs with a 13,5T brushless sensored motor.

-Uses easy to find belts from Schumacher K1 buggy.

-Can use CV axles from multiple brands (Kyosho, Tamiya, Schumacher, Basher, Quanum, FTX and more).

-Wrap around body is held on without clips or velcro and keeps dirt out.

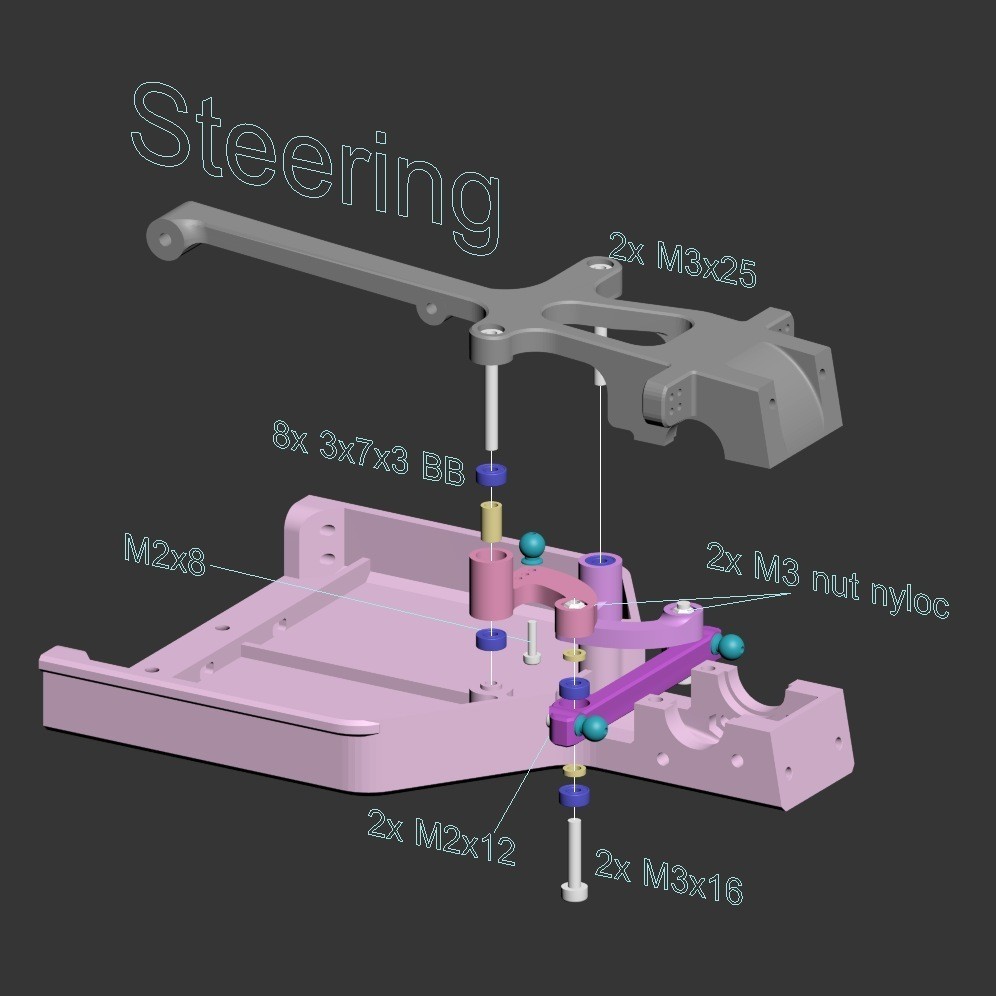

-Super precise steering thanks to ball bearings in all hinges.

-Small turning radius.

-Radial shock positions ensure minimal height change with shock adjustment.

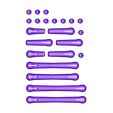

-Printable high strength gear, sealed gear or ball diff option.

-Supports FS Racing steel gear diff with adapters.

-Printable 48dp pinion and spur gears.

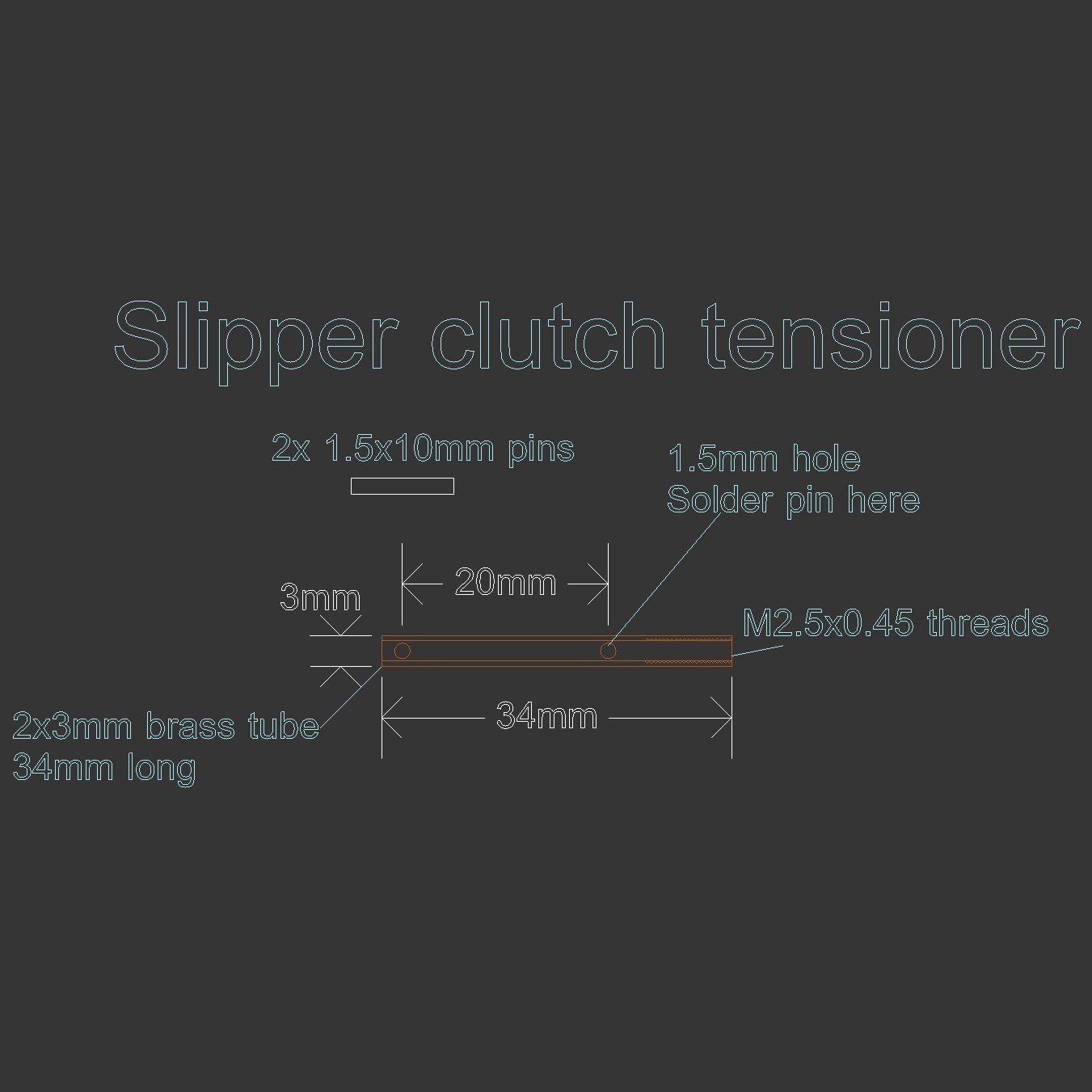

-Printable slipper clutch option.

-Sway bar option front and rear.

-Two body styles to choose from.

-Many adjustment possibilities.

-Designed to comply with ROAR regulations.

-Easy to use shorty battery mount without clips.

Dimensions:

Wheelbase: 283.3-289.3 mm (adjustable with different rear arms)

Width: 249 mm (With quanum Vandal front CVD's and zero camber)

Front and rear track: Adjustable with different hexes.

Final drive gear ratio: 2.125:1 with 16t layshaft. 2:1 with 17t layshaft

Chassis length: 358.5 mm

Assembly notes:

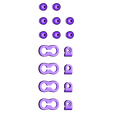

-Option parts to use FS racing steel gear diff (Part 511687) can be made, though they aren't needed in my opinion, as the printable gear diff has not caused problems for me at all. The pulley part replaces the outside bevel gear on the FS diff and the spacers are used inside the 12x18x4 bearings on each side of the diff. This diff works with CVD shafts that have <2 mm pin and <6mm ball on the dogbone end.

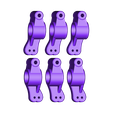

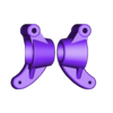

-The Spindlefront02-Ackerman and Steering02-Ackerman steering and spindle pieces add more ackerman-compensation than the stock parts.

-Universal adjustable 110-120mm CVDs can be used now. The option files have spindlerear and spindlefront 110-120 names. The rear one needs to be filed and shortened slightly, but this is easy to do and takes seconds with a file and bolt cutter. Look at the added photo for examples of the work.

-If you can't find CVD axles of the right length then it's possible to order ones that are too long and then cut them shorter and silver solder/braze or weld together. I have done this myself with vintage cars that don't have parts available any more. If you don't have the ability to braze you can use a shaft coupler like this:

https://www.banggood.com/3-17mm-to-3-17mm-Brass-Motor-Coupler-Shaft-Coupling-Connector-for-EleksMill-Engraver-CNC-Router-Spindle-Motor-p-1271964.html?

p=HD240528697332015103&custlinkid=130156

-CVD axles with short wheel axles can use the file "Option - Spindlerear-shortaxle.STLOption - Spindlerear-shortaxle.STL" instead of the regular rear spindles. These are only 10 mm thich from bearing to bearing.

-The sealed diffs are the strongest. They use 20 inner diameterx2mm O-rings to keep the grease in. They are not intended to be filled with silicone fluid, but rather made to keep the grease in.

-Removing the support pieces from the diff parts easily: https://youtu.be/vsvI2rdywOM

-Do not over tighten any screws. Screws threaded into plastic only need to be snug. Stripped threads can be refreshed with a thin layer of CA glue, or just reprint the parts. That's the cool thing about printed cars.

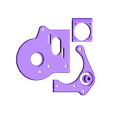

-A PLA motor mounting plate can deform if the motor gets hot. If this is a problem, print the motor plate from PETG, ABS or nylon, or another more heat resistant material.

-The middle piece of the motor mount assembly has two small holes for mounting a small 25 mm fan. It will aid with motor cooling by circulating air inside the body and directing it over the motor.

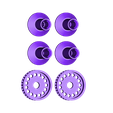

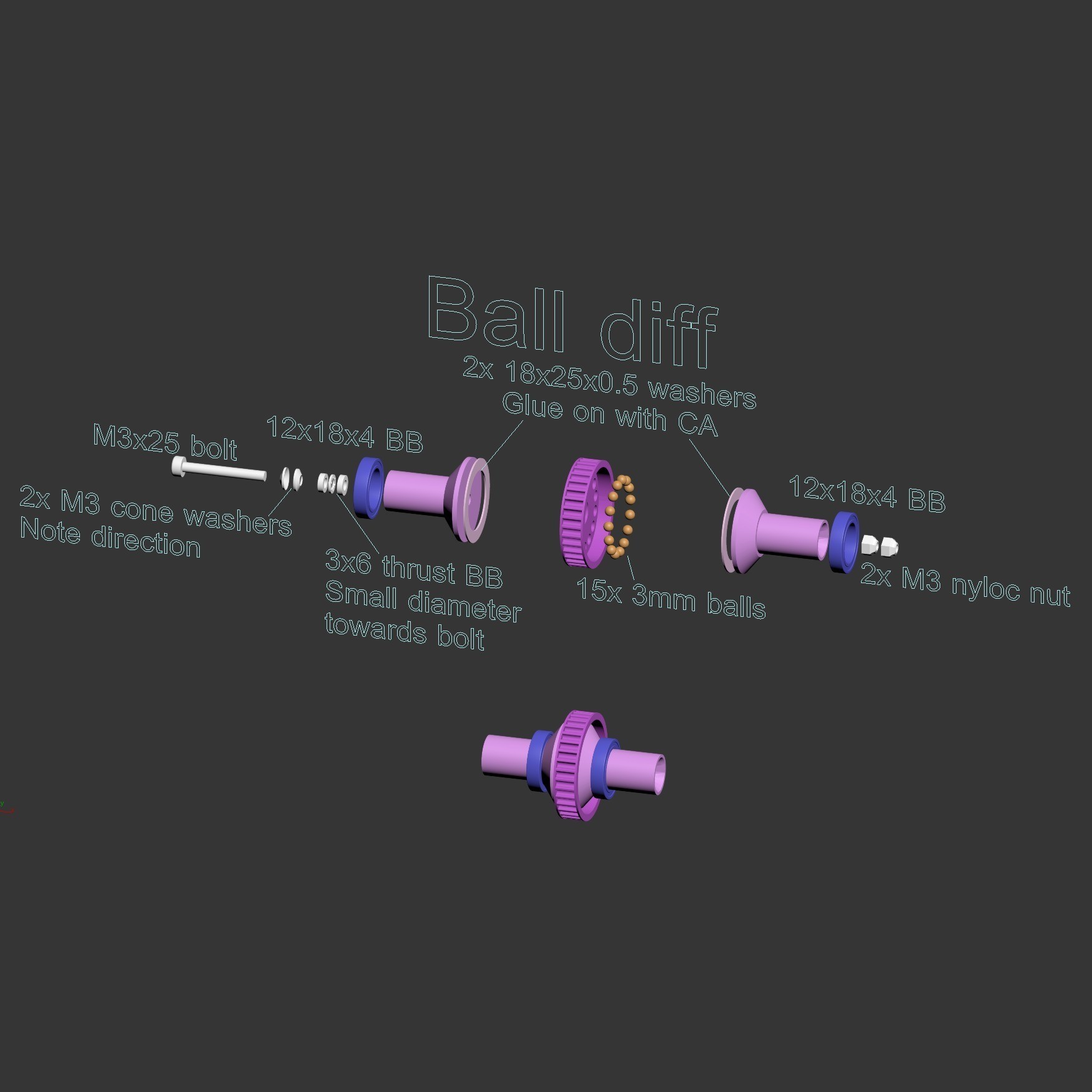

-I recommend using a gear diff in the rear if it's difficult to avoid slip. If the ball diff screw comes loos while driving I recommend adding a drop of thin CA on the end with the nut after tightening to the correct tension. The nature of PLA is such that it can deform over time and loosen the diff.

-Ball diffs must not slip noticeably. If they do the pulley part of the diff will deform from heat. To adjust the diff tension loosen the camber link on the side where the bolt head is, insert an allen wrench and turn the opposite wheel to tighten or loosen.

-If the ball diff tension loosens, add a drop of thin CA to the nut end of the diff after adjusting.

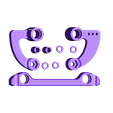

-Gear diffs spin more freely than ball diffs. Use this info to tune the car. A good starting point is gear in the rear and ball in the front. The gear diffs are called Gearediff. The gear diffs should not have a lot of side to side play in the seats in the chassis, or they will break. Print "Diffspacer.STL" to adjust this play. Diffspacer.stl canbe scaled in the Z-axis to make it thicker.

-Suggested setting for links. Measured on outer ends:

Front camber links: 67mm

Steering links: 69 mm

Rear camber links: 77 mm

I suggest starting off with the link in the innermost and uppermost holes.

-The option parts contain various rear spindles and pivot blocks for changing the rear anti squat or toe in. The amount is marked on the parts and should be visible after printing.

-I suggest starting with the shocks in the center holes on both top and bottom.

-The shock adapters allow the use of aftermarket big bore springs with the suggested shocks below. The stock springs are too hard.

-The printable shock pistons are an upgrade from the ones included with the cheap shocks. I suggest one hole and ~550 CST shock oil for starters. It depends on your track and temperature.

-The shock covers fit over the top of the rear shocks and screws and protect the shock from damage, while also protecting the track surface from damage.

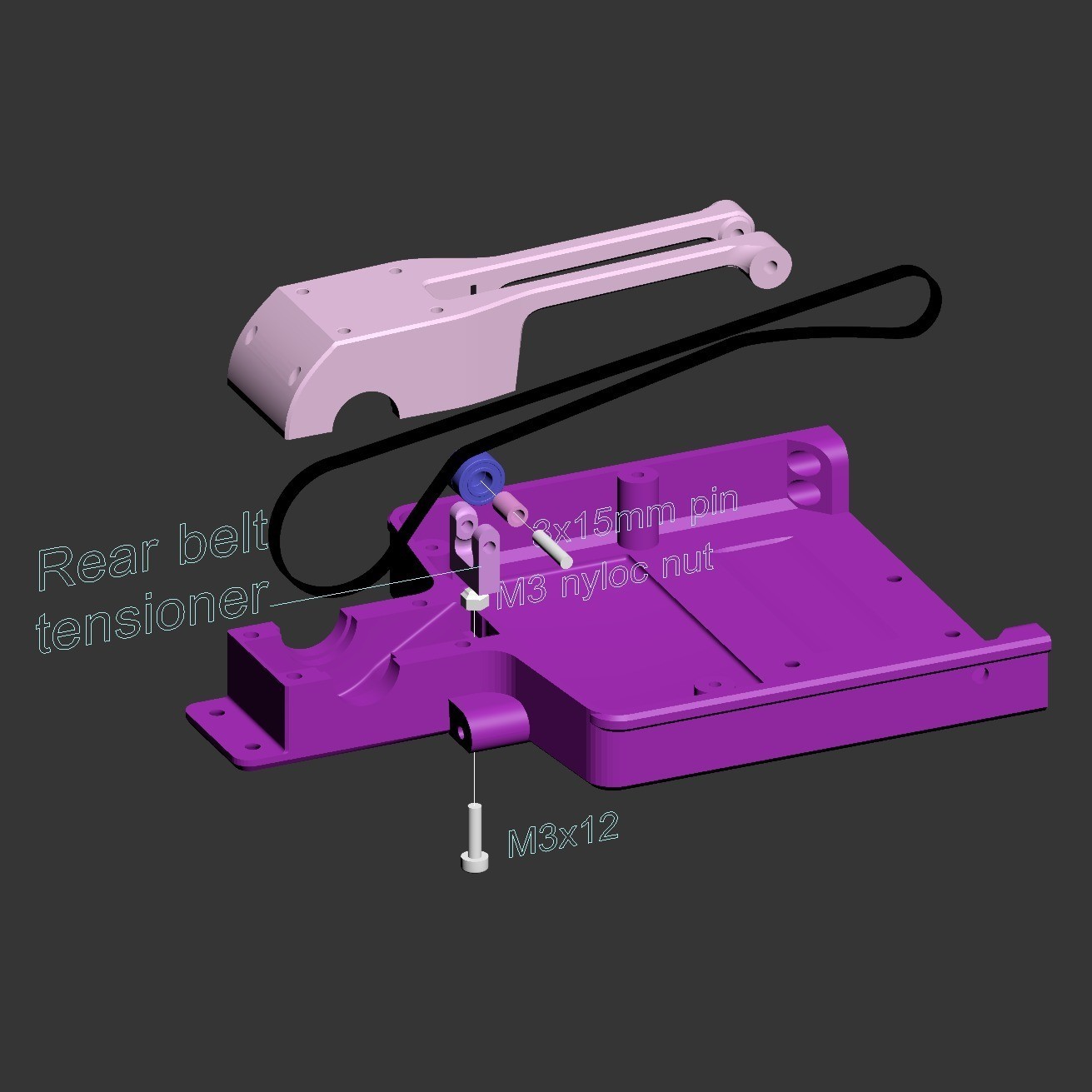

-The rear belt tensioner pushes up on the belt to tension it. It is accessed by a central screw from the underside of the chassis.

-The printable wheels have the same offset and width as competition Schumacher wheels.

-The body can take some practice to install. The trick is to tuck the nose in first, flex the front edges of the bod around the steering posts and then it will go on quite easy. There is no need to cut to make it fit. Check the video I posted above of installing and removeing the body.

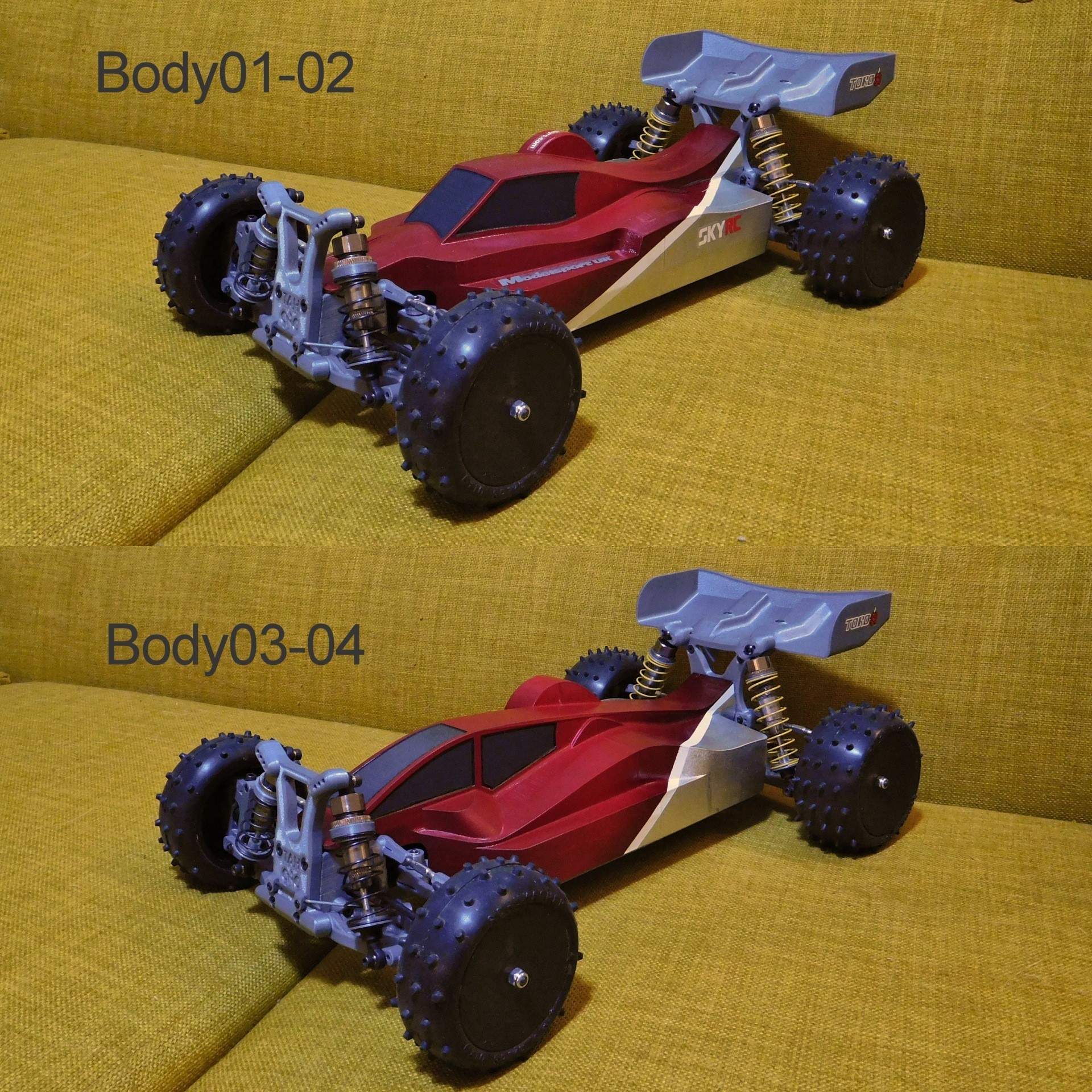

-Body01-02 is the cab forward body

-Body03-04 is the futuristic body

List of required purchases. Many links contain my affiliate code so that I get a small kickback from your purchase on the sites. It does not cost extra because of this, but helpsme out a lot:

Electronics:

-Minimum 2 channel transmitter and receiver. Cheap:

https://www.banggood.com/Flysky-FS-GT2E-2CH-2_4G-RC-Controller-Transmitter-With-Receiver-p-1086215.html?p=HD240528697332015103

This is better:

https://www.banggood.com/Flysky-FS-NB4-FS-TR4-2_4G-4CH-Noble-Radio-Transmitter-HVGA-TFT-Color-Screen-for-Rc-Car-Boat-p-1306766.html?p=HD240528697332015103&custlinkid=436073

-Your motor and ESC of choice? 13.5T sensored recommended.

Or the cheap option:

https://www.banggood.com/Racing-60A-ESC-Speed-Controller-F540-3000KV-Brushless-Motor-For-110-112-RC-Car-p-1175462.html?p=HD240528697332015103

-A good servo:

https://www.banggood.com/JX-Servo-PDI-6208MG-8kg-Servo-120-Degrees-High-Precision-Metal-Gear-Digital-Standard-Servo-p-1070889.html?p=HD240528697332015103

Hardware:

-Spur gear. For example

Associated 48Dp:

https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2FASC9653-84T-48P-Spur-Gear-B4-T4-SC10-Fast-Shipping-With-Tracking%2F172164286905

Pinion:

https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fc%2F2019038613

-Servo saver. I recommend this one: https://hobbyking.com/en_us/kimbrough-mid-size-servo-saver-with-hole.html

-Schumacher k1 120t and 132t belts. Also available via Ebay:

http://www.toughracing.com/zc126d/index.php?main_page=product_info&products_id=2456

http://www.toughracing.com/zc126d/index.php?main_page=product_info&products_id=2457

-Universal CVD's: https://www.ebay.com/itm/2Pcs-Adjustable-110-120MM-Joint-Steel-Shaft-CVD-for-HSP-94118-94107-94111/233883876220?mkcid=1&mkrid=711-53200-19255-0&siteid=0&campid=5338226872&toolid=11800&mkevt=1

-Also needed are one 10x15x4 ball bearing per axle: https://www.ebay.com/itm/Ball-Bearing-10x15x4-Rubber-Seal-Tamiya-Tuning-1-St-5-St-10-St/263900551756?mkcid=1&mkrid=711-53200-19255-0&siteid=0&campid=5338226872&toolid=11800&mkevt=1

-Quanum vandal Front CV axles or BSR BZ-444 front CV axles (clones like FTX Vantage fit as well):

https://www.modelsport.co.uk/ftx-front-cvd-set-vantage-hooligan/rc-car-products/365769

https://www.ebay.com/sch/i.html?_from=R40&_nkw=Ftx6222&_sacat=0&_sop=15

https://hobbyking.com/en_us/front-cvd-1-10-quanum-vandal-4wd-racing-buggy-2pcs.html?affiliate_code=BSFWYBUNYWDKXJN&_asc=9130832446

https://hobbyking.com/en_us/front-cvd-bz-444-pro-1-10-4wd-racing-buggy-2pcs.html?affiliate_code=BSFWYBUNYWDKXJN&_asc=3929904396

-BSR BZ-222 rear CV axles or BSR BZ-444 rear CV axles (FTX Edge, clones and other rear competition buggy CVD's should fit as well):

https://www.modelsport.co.uk/ftx-edge-rear-cvd-set/rc-car-products/366753

https://www.ebay.com/sch/i.html?_from=R40&_nkw=FTX6721&_sacat=0&LH_TitleDesc=0&_sop=15

https://hobbyking.com/en_us/rear-cvd-bz-444-pro-1-10-4wd-racing-buggy-2pcs.html?affiliate_code=BSFWYBUNYWDKXJN&_asc=1772075197l

https://www.modelsport.co.uk/team-c-rear-cvd-shaft-2-2wd-buggy-ar125000522-/rc-car-products/375768

-Optional steel diff:

https://www.banggood.com/FS-Racing-110-RC-Car-Spare-Parts-Differential-Assembly-511687-p-1000258.html?p=HD240528697332015103&custlinkid=828371

-90 mm front shocks (~81 mm eye to eye center): https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2F2pcs-Titanium-90mm-F104004-Adjustable-Shock-Absorber-for-RC1-10-Off-Road-Car%2F152475343522

-100 mm rear shocks (~91 mm eye to eye center): https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2F2pcs-100MM-Alloy-Shock-Absorber-Damper-For-RC-Model-Car-1-10-Axial-SCX10-SCX0018%2F333361429716

-40-45 mm long 3mm tie rods for the adjustable option. Threaded rod can be used in a pinch. These fit perfectly:

https://hobbyking.com/en_us/adjustable-alu-tie-rod-set-m3xl40mm-5pc.html?affiliate_code=BSFWYBUNYWDKXJN&_asc=1945953166

https://hobbyking.com/en_us/adjustable-alu-tie-rod-set-m3xl45mm-5pc.html?affiliate_code=BSFWYBUNYWDKXJN&_asc=5906135853

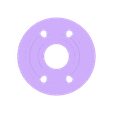

-4x 18x25x0,5 washers for ball diffs: http://www.ebay.com/itm/Shims-DIN-988-compensation-washers-spacer-washers-ø-6-100-mm-Shim-ring/262968954788

-30x 3mm hardened steel chrome or ceramic balls for ball diffs: https://rover.ebay.com/rover/1/711-53200-19255-0/1?ff3=4&toolid=11800&pub=5575353675&campid=5338226872&mpre=https%3A%2F%2Fwww.ebay.com%2Fitm%2F250-PCS-3mm-G10-Hardened-Chrome-Steel-Loose-Bearing-Balls%2F290959326207

-Slipper clutch spring:

https://www.ebay.com/sch/i.html?_from=R40&_nkw=Associated+9605&_sacat=0&_sop=15

-2x 30mm diameter steel washers for slipper clutch.

-8x 12x18x4 ball bearings.

-12x 3x7x3 ball bearings.

-12x 5x11x4 ball bearings.

-2x 3x6 thrust bearings.

-2 mm piano wire to make pins.

-1.5 mm piano wire to make pins and sway bars.

-3x15 mm brass tube for rear tensioner.

-2x 3x20 mm brass tube for gear diffs.

-2x 3x28 mm brass tube for rear spindles.

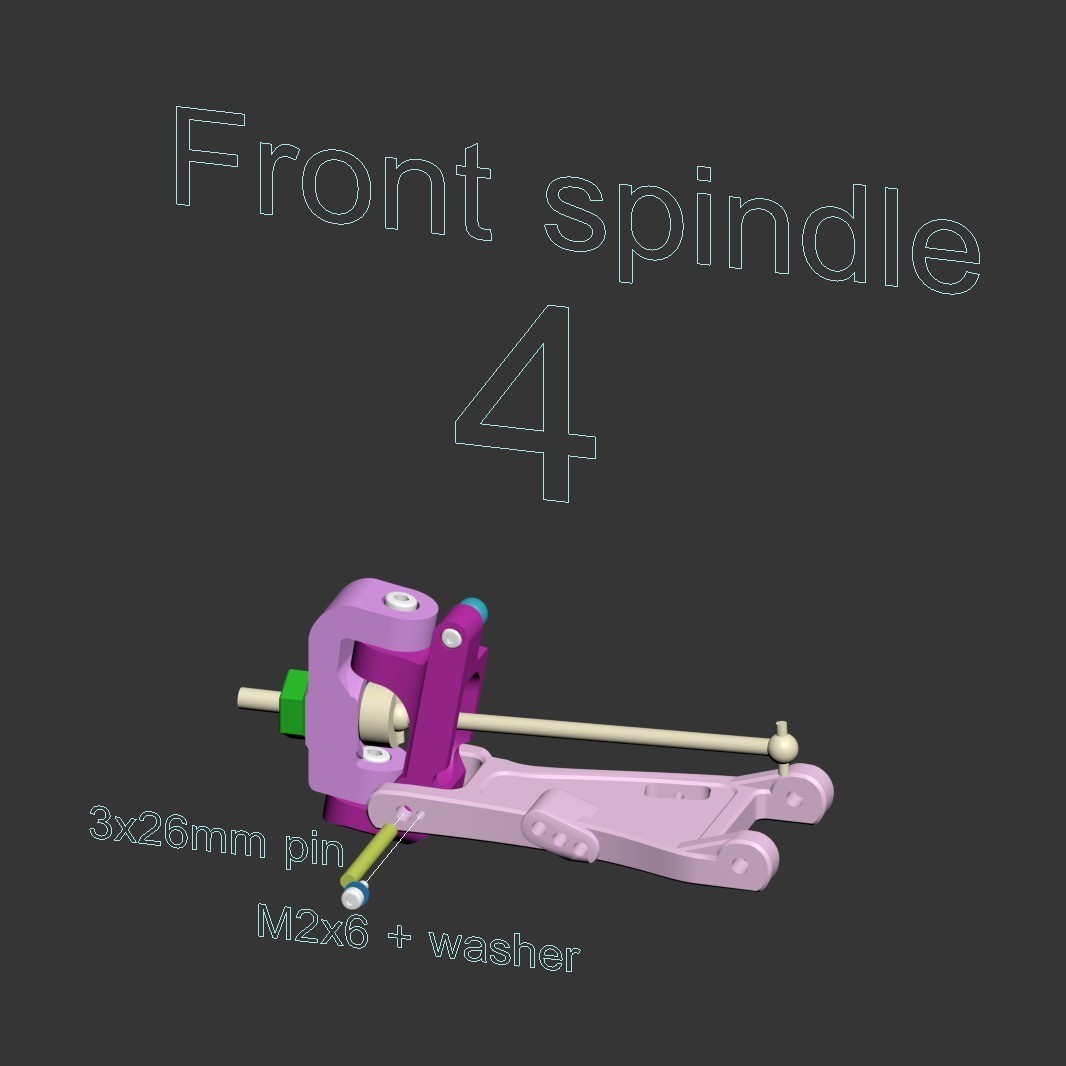

-2x 3x26 mm brass tube for front spindles.

-3x34 mm brass tube for slipper clutch shaft.

-2x 3x48mm brass tube for rear suspension arms.

-2x 3x45mm brass tube for front suspension arms.

Screws:

-4x M2x6 + M2 washers.

-6x M2x8.

-14x M2x12.

-10x M3x8.

-23x M3x12.

-10x M3x16.

-1x M3x20.

-2x M3x25.

-2x M3x34.

-1x M4x16

-11x M3x12 countersunk.

-5x M3x20 countersunk.

-6x M3x25 countersunk.

Nuts:

-15x M3 nyloc.

-4x M4 nyloc

New option parts will appear as new free items on Cults3D.

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/8f643b29-5242-4381-b017-bfcded48c9a9/MKultra10.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/8d7f282e-3db1-45b2-be35-63665619e9ee/DSCN0234.JPG)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/c9aab0c5-180c-490b-a5f4-8e94c1844d81/14408.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/7780a36d-7a2b-40c6-b30e-df863c6c52c0/mr206.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/cc442c4c-9dd4-4894-ab69-aab4951ca885/TH8-mount02.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/8ad27b5c-14cd-470e-8709-5101b727d494/DSCN1603%5B1%5D.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/7c87325a-eeef-4bc0-80a6-91763ab42a97/Melusine21.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/3c1f942f-ab3a-44c1-b403-0e8f61876066/EL-39-59.jpg)

/https://fbi.cults3d.com/uploaders/12943812/illustration-file/59247544-6863-465f-8b9f-868e43476735/FWD24.jpg)