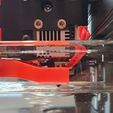

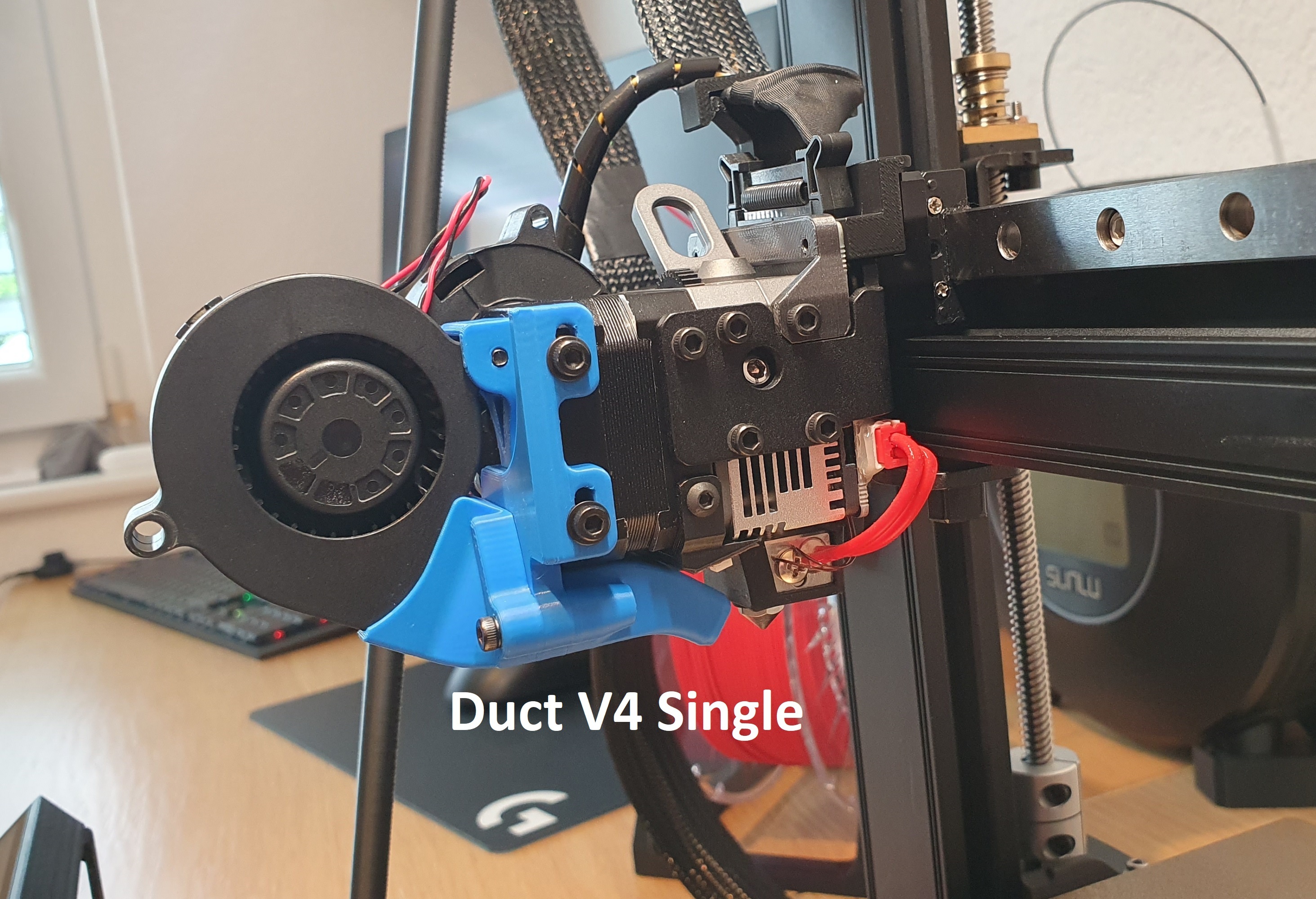

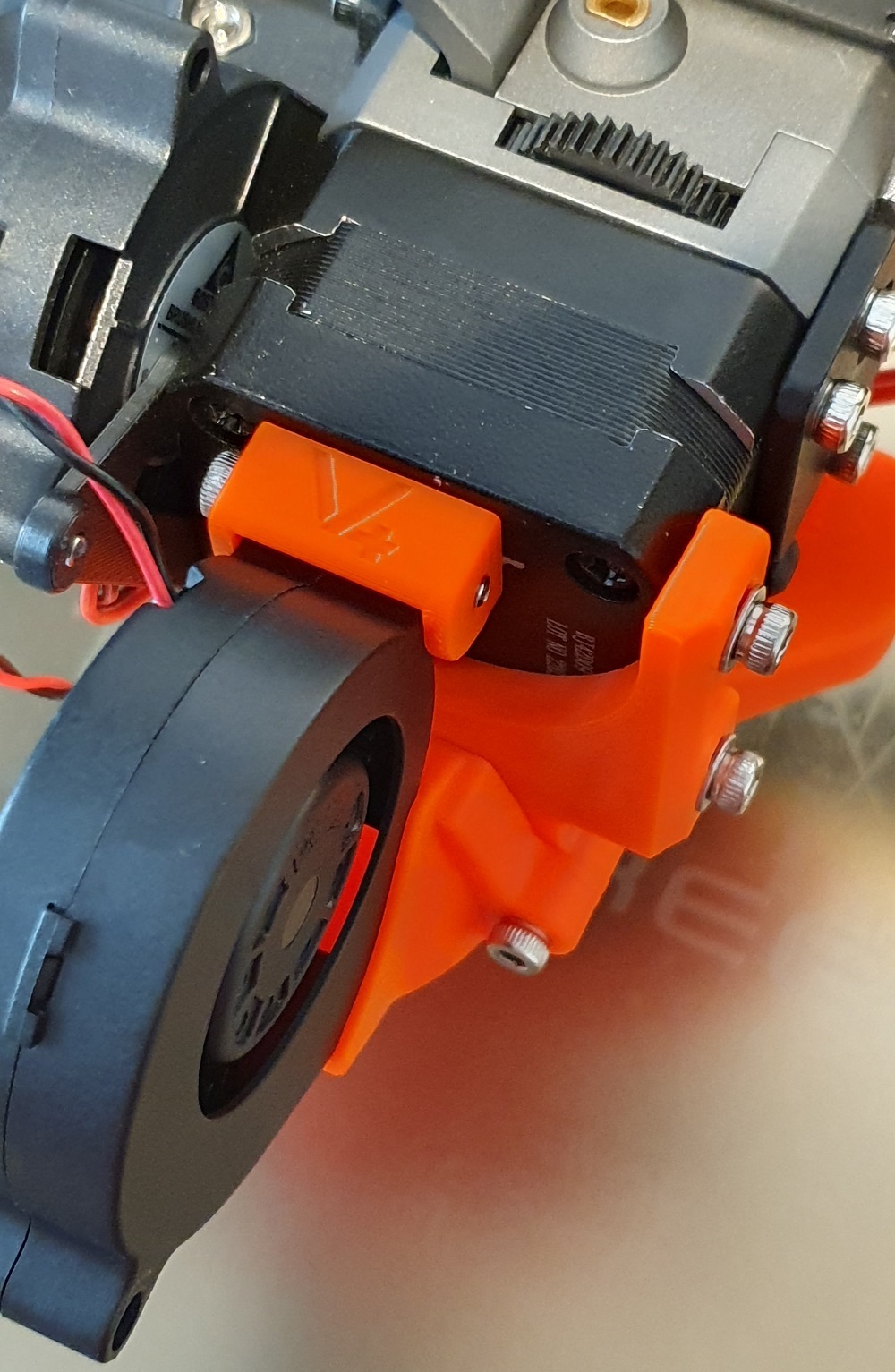

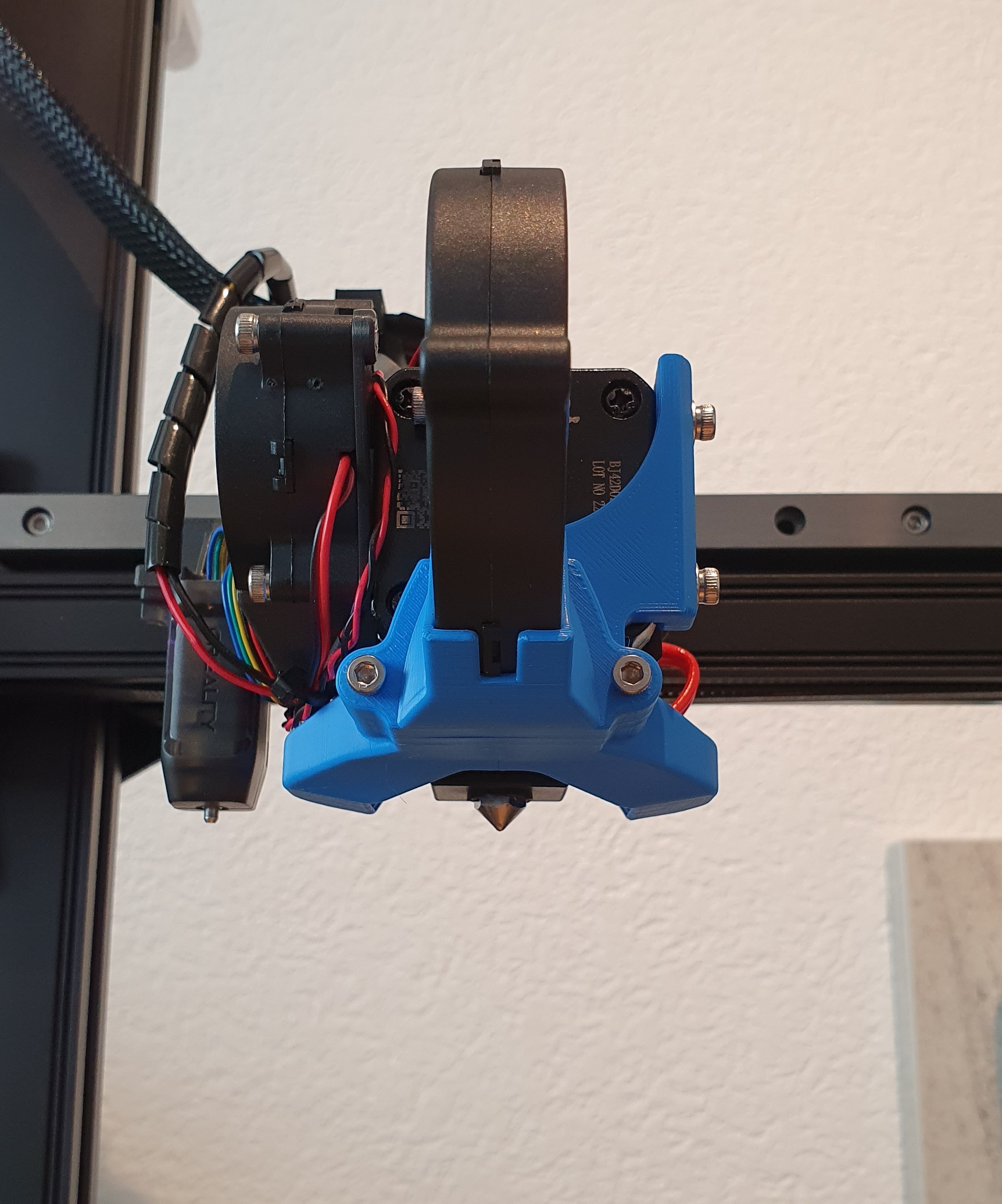

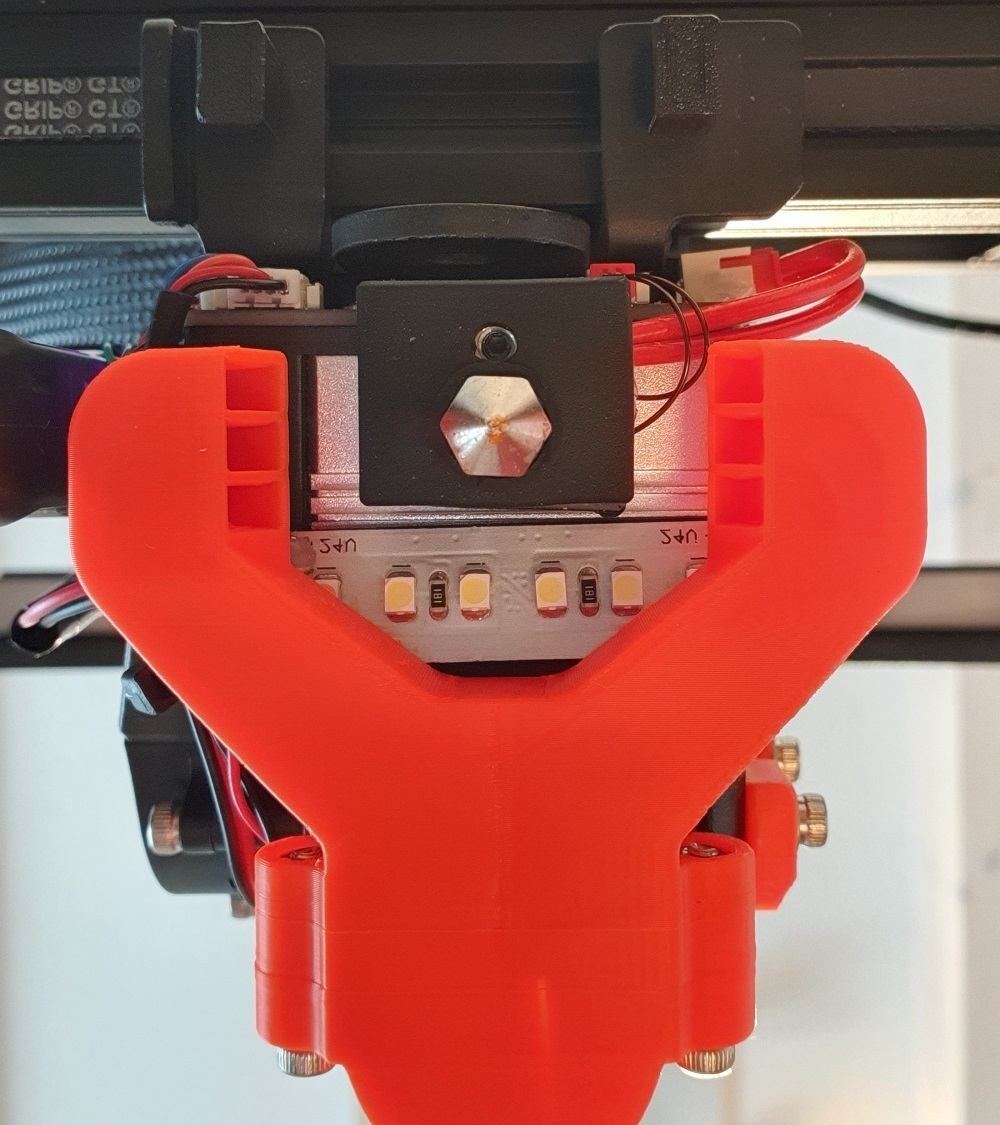

High-performance material cooling system for Sprite/Pro extruders (Ender 3 S1, S1 Pro, S1 plus, CR-M4...).

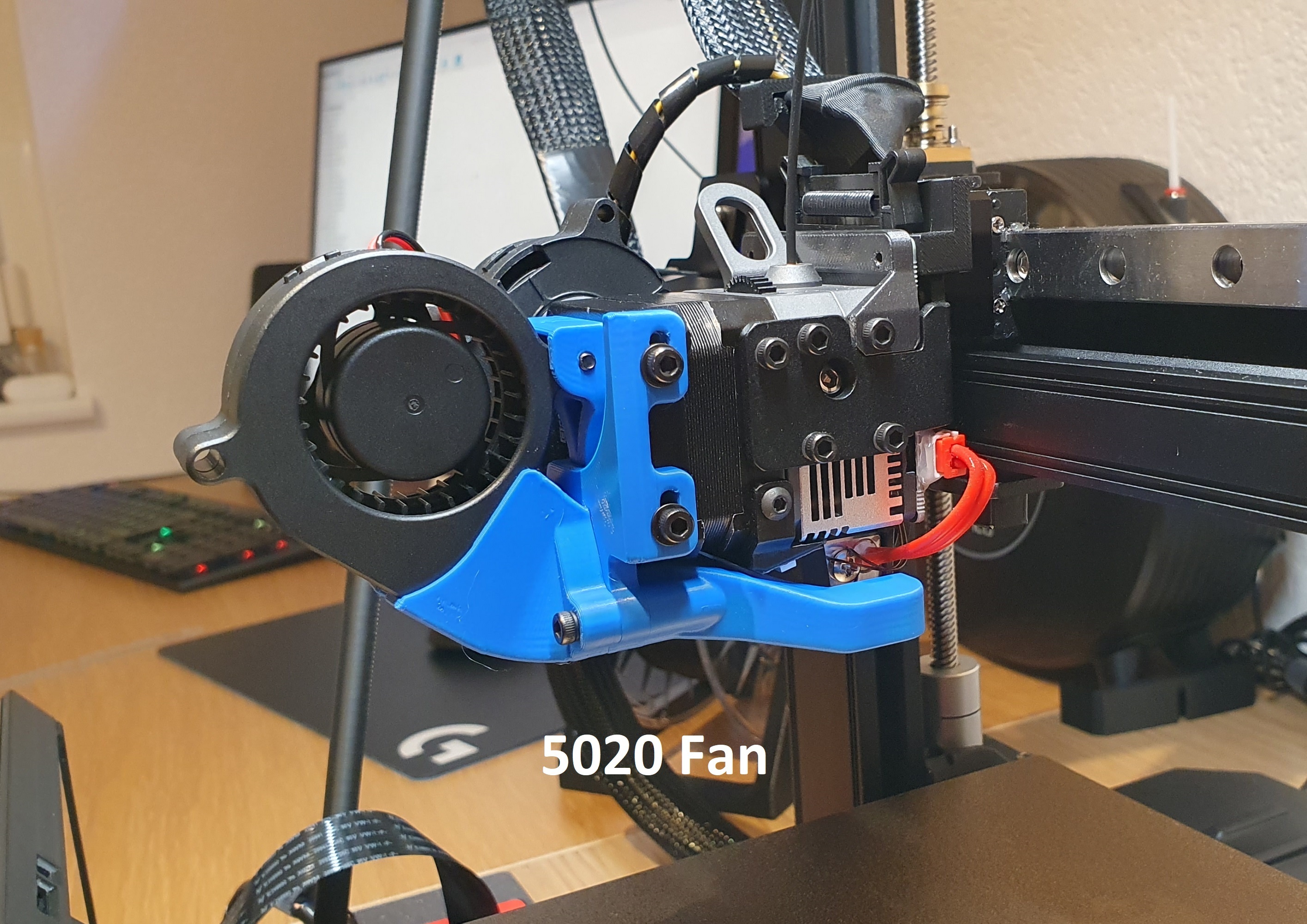

Designed for a 5015 or 5020 fan.

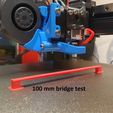

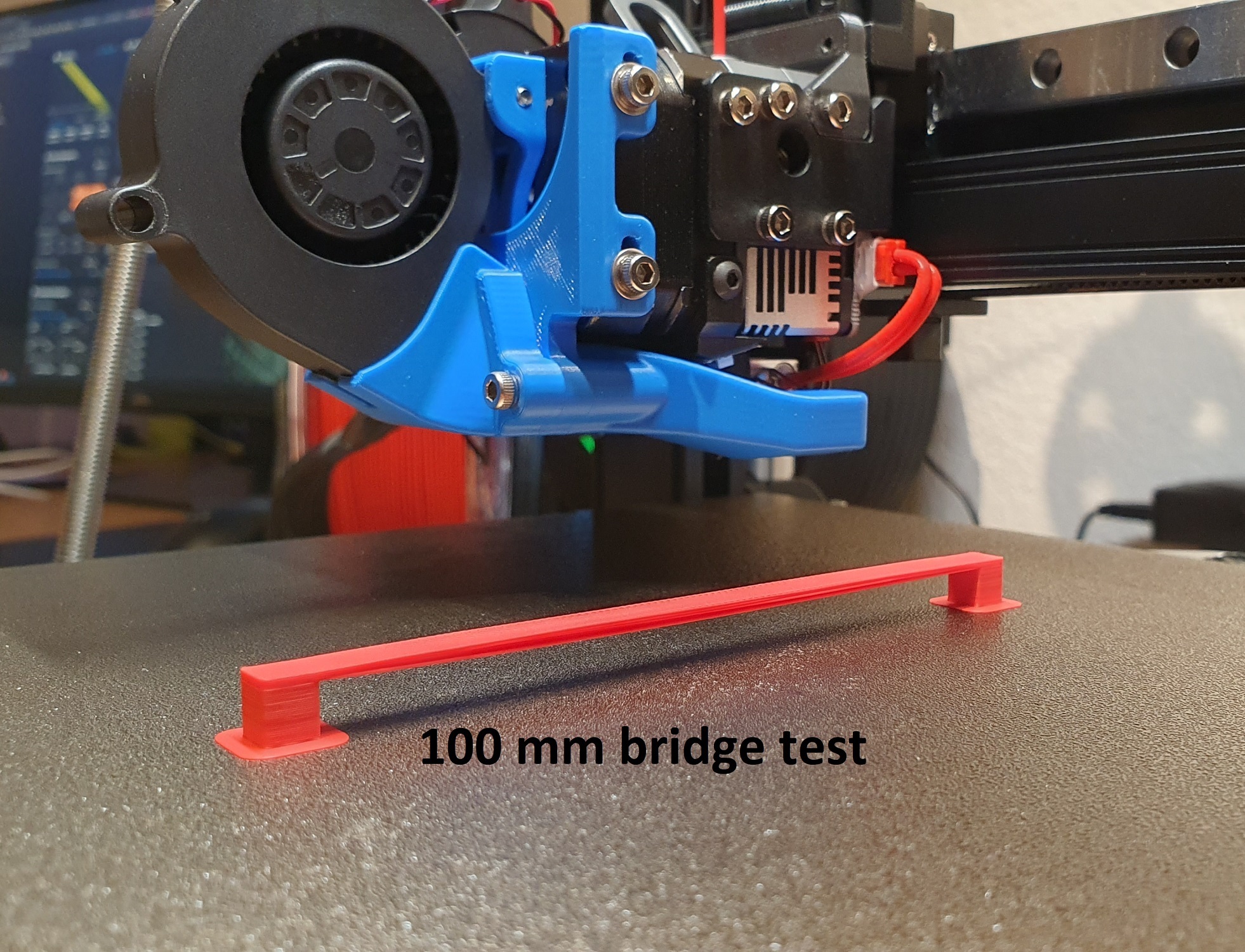

Video of test on 100 mm bridge

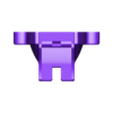

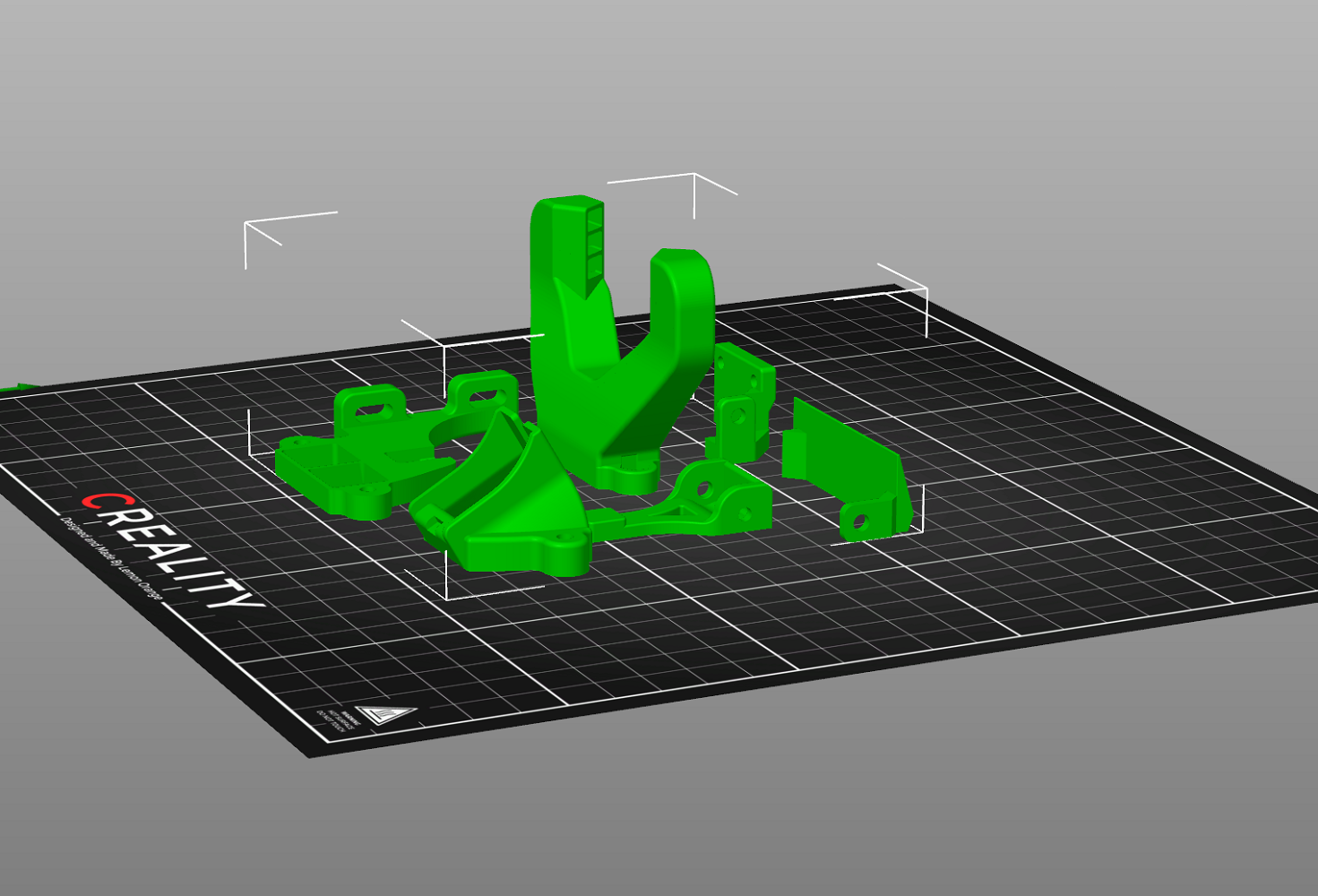

*This design includes only the parts shown in purple in the first image.

It is compatible with the original fairing (3010 hot end fan) and also with my design for the 4020/5015 hot end fan and probe relocation.

Design features:

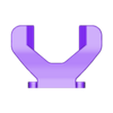

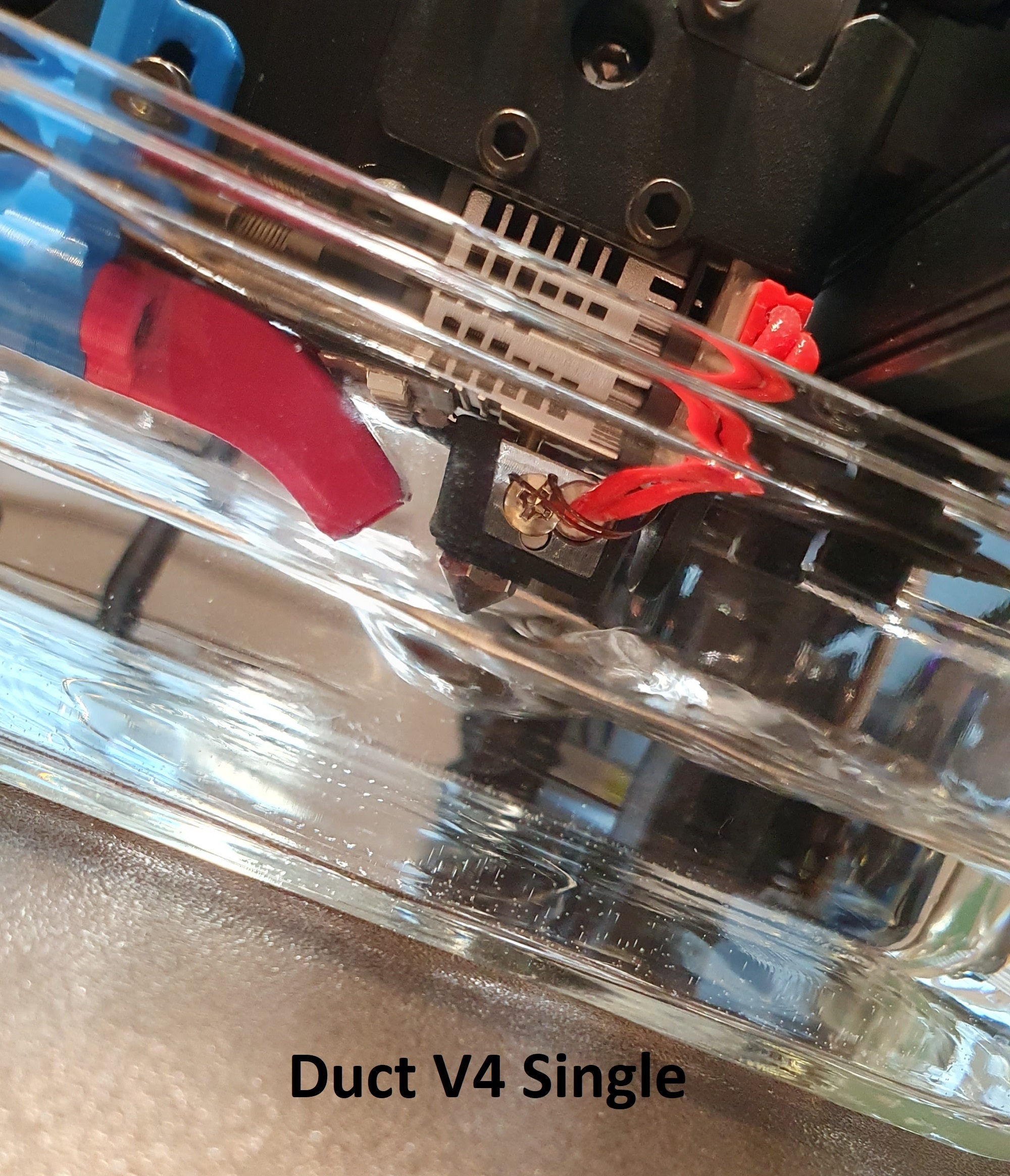

The V4 design uses a 2 or 1 duct architecture (single duct not compatible with Creality's high flow kit). The fan is placed in the axis of the nozzle, allowing very direct flow.

The dual-duct architecture allows good visibility of the print on the front and greater clearance with the platen and around the hot end, so that an improved hot end kit like the Creality high flow or longer hot ends like the ceramic "Volcano" can be mounted.

Not a replacement or upgrade for V3, but a variant in design and architecture.

The V4 design is as effective as the V3 with a small advantage in my very high-speed tests on overhanging perimeters.

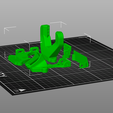

The design is conceived in several parts to facilitate printing. There's no need for supports if your printer is well calibrated and capable of producing overhangs and small bridges.

Choose a good quality 24v fan to avoid voltage changes.

The added weight compared to the original parts (4010 radial fan and stainless steel fairings) is +16 grams WITH the 5015 fan and assembly screws (without LED support and accelerometer).

5015 or 5020? :

Between my Sunon 5015 and my GDSTime 5020, the 5015 is better in cooling, but noisier (higher rotation speed).

To sum up, if you're looking for maximum efficiency, use a 5015. If you're not significantly increasing your speeds, the 5020 will be more suitable.

Assembly and hardware:

You'll find an assembly help file with more information in the download files.

Fan mounting screws :

Optional mounting :

2x M3 nuts or 2x threaded heating inserts (for conduit)

Optional 2x M3 screws 6 to 8 mm (depending on your accelerometer)

Optional 1x M3 5 mm screw (LED strip holder)

Accelerometer holder:

For mounting an accelerometer such as ADLX345, Creality Sonic Pad or USB model such as KUSBA or FYSTEC.

Screw the accelerometer first onto the bracket with two screws. If the screws protrude just a little (maximum 1.8 mm), it's even better, as they'll provide support against the extruder motor.

Then screw the support to the printer, replacing the 8 mm screw at the top of the central plate with a 10 mm screw.

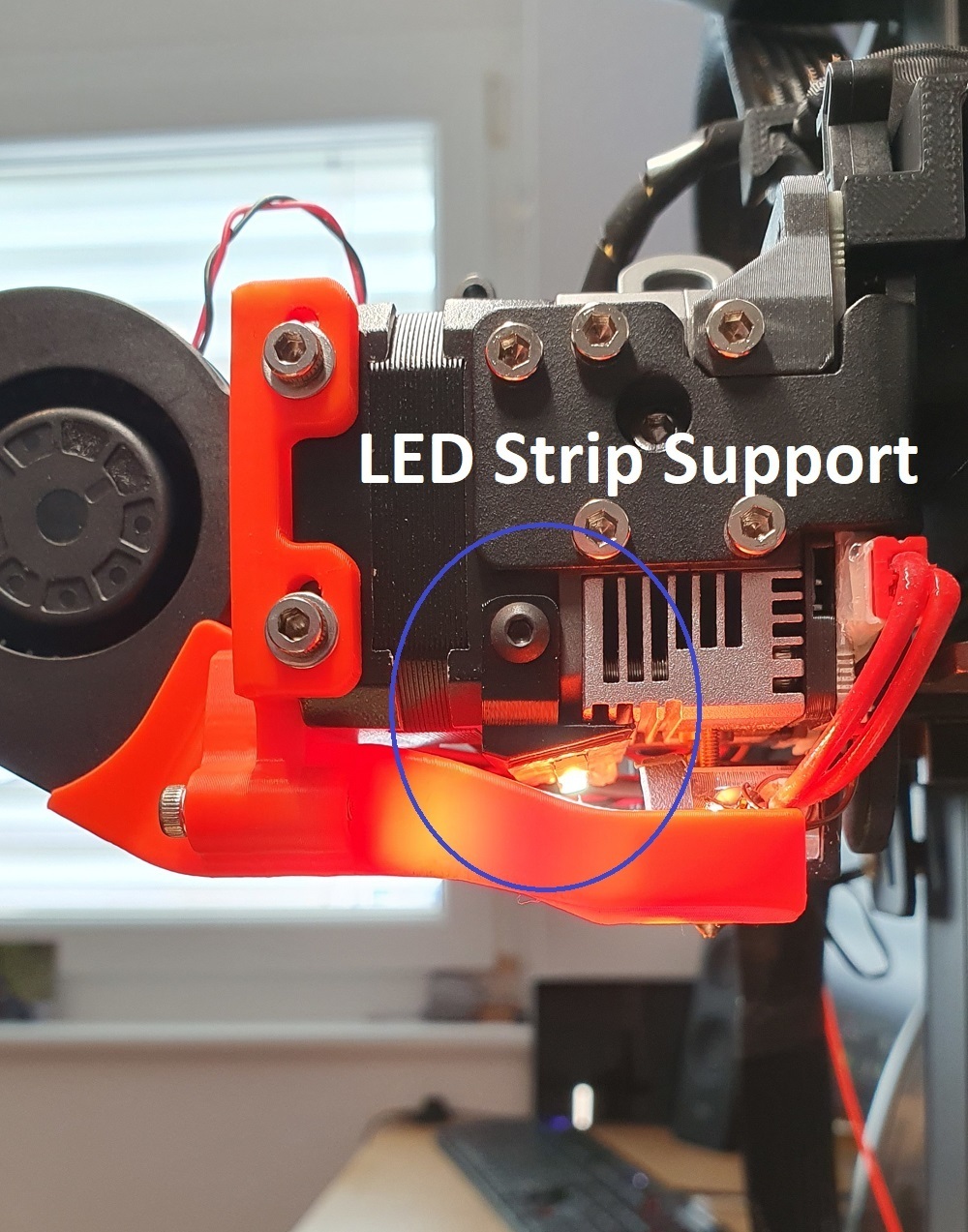

Accelerometer and LED strip support:

Accelerometer holder for ADLX345, Creality Sonic Pad or USB-C type KUSBA, FYSTEC, Mellow Fly...

LED strip holder, maximum dimensions 42x13 mm. You can use a 24V LED strip connected directly to the printer power supply or use something like this link.

*Thanks to Kingsidorak for modeling the extruder.

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/35624b4a-ab0b-4ea0-9fac-3631fc33926c/Fan-Duct-V4-5015-bordure.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/5e00c6e4-bd65-4f99-bc78-040a3742cd5c/Support-bobine.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/340cb4fe-0f45-4cb0-ab90-669828bfec3d/Dessin-photo.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/81903c3e-09d1-4e20-89ad-bce2dc2c421c/Fan-Duct-V3-5015-1.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/958ccec7-dd9d-4a85-a743-4b8ac35fec22/20220925_133547.jpg)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/54632572-686a-4ff5-81fc-dd50ffbfaf4d/20221009_164936.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/f11e176e-20eb-48f7-be5a-ea96cc94f330/1-Hotend-4020.png)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/369597a6-e868-4f60-b621-3783ff03cb1a/1.jpg)

/https://fbi.cults3d.com/uploaders/23882450/illustration-file/fc557357-11b2-48f4-8959-52fd91283c2f/1.jpg)