3D model description

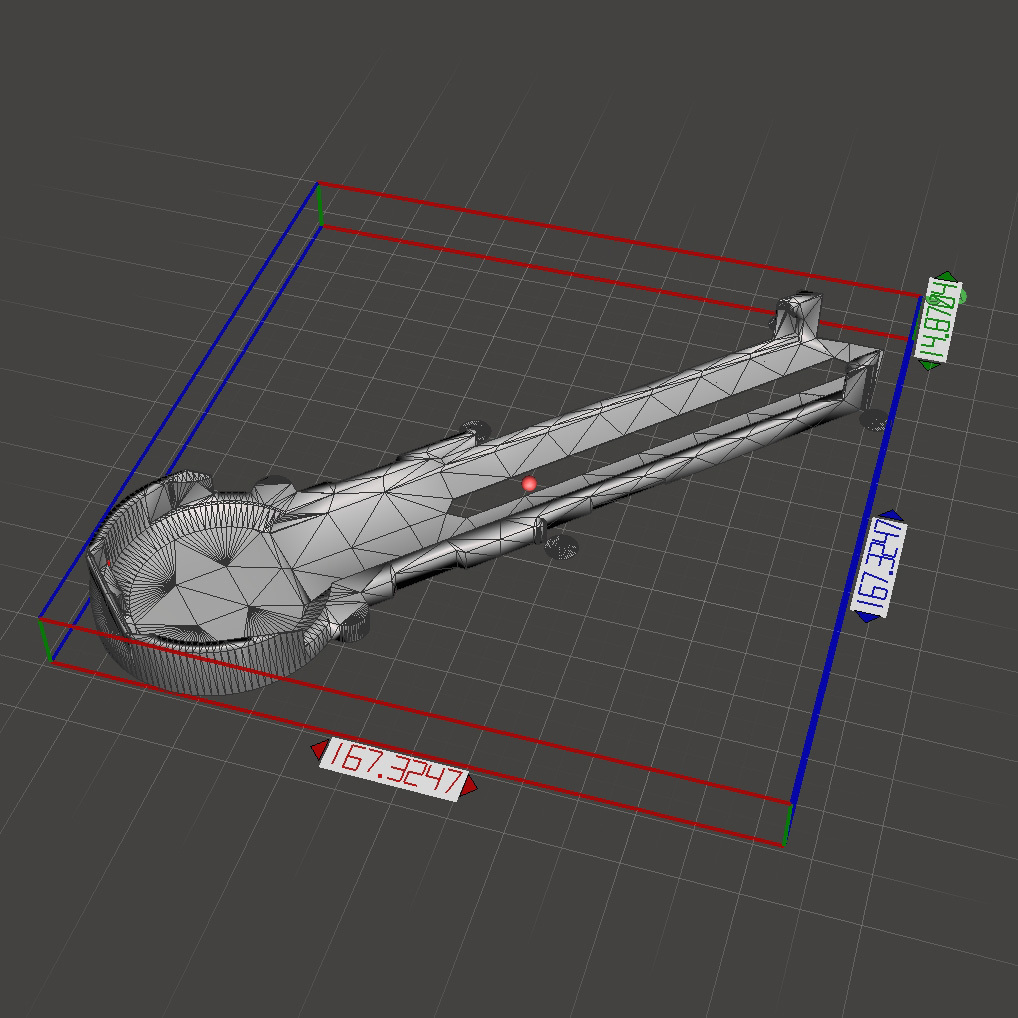

This is my first Assassin’s Creed inspired hidden blade 3D model (Syndicate edition) equipped with a unique mechanism, every single detail of that is 3D printable, except for a nylon cord. There’s no need for screws, nuts, springs, magnets, ball bearings or even rubber bands. All you need is 100g of standard PETG filament and a piece of nylon cord (0.6-0.8mm thick).

[UPD Oct.03.2023: a version for PLA was added, where a 3D printed spring is replaced with a rubber band. It also works with PETG]

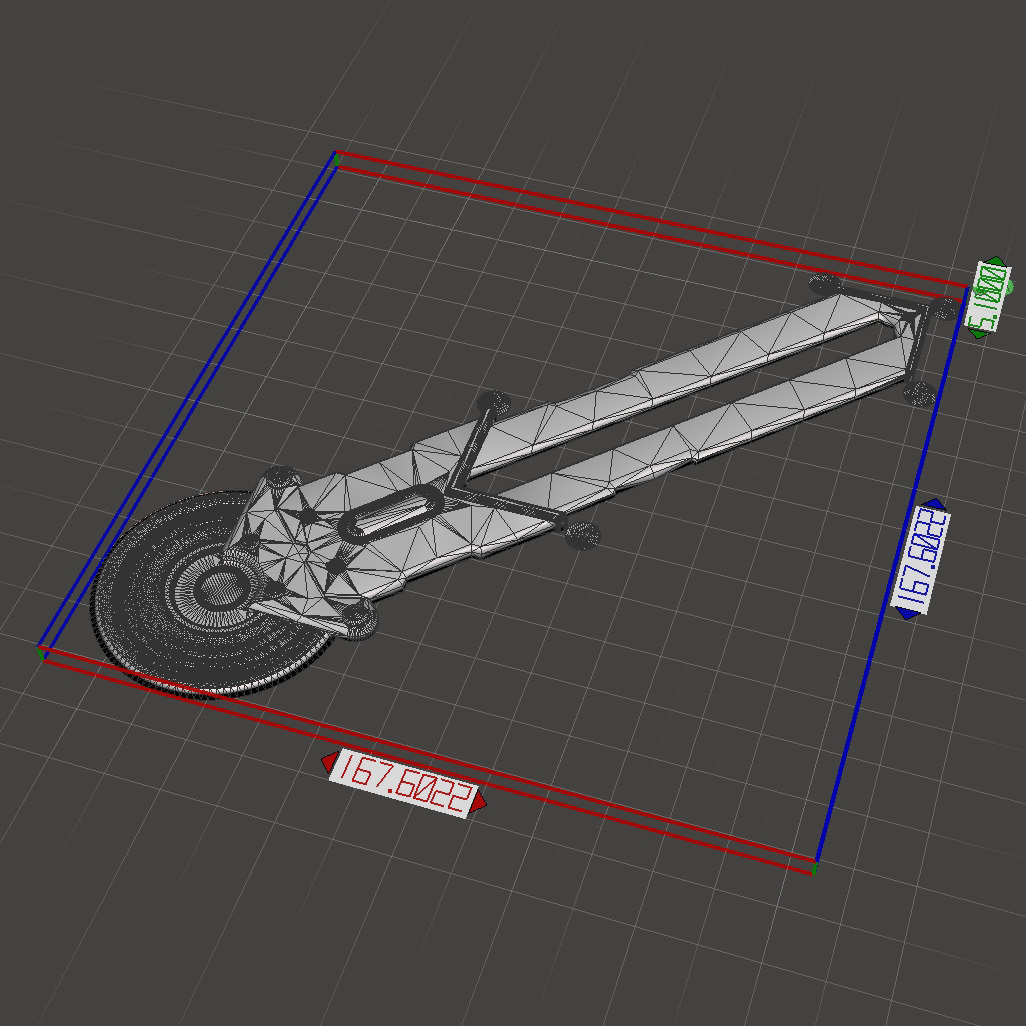

An assembly approach has been inspired by the handguns assembly process, which can be done in a matter of seconds by using no tools. By combining several functions in each detail of the mechanism I managed to reduce the overall number of them down to 11.

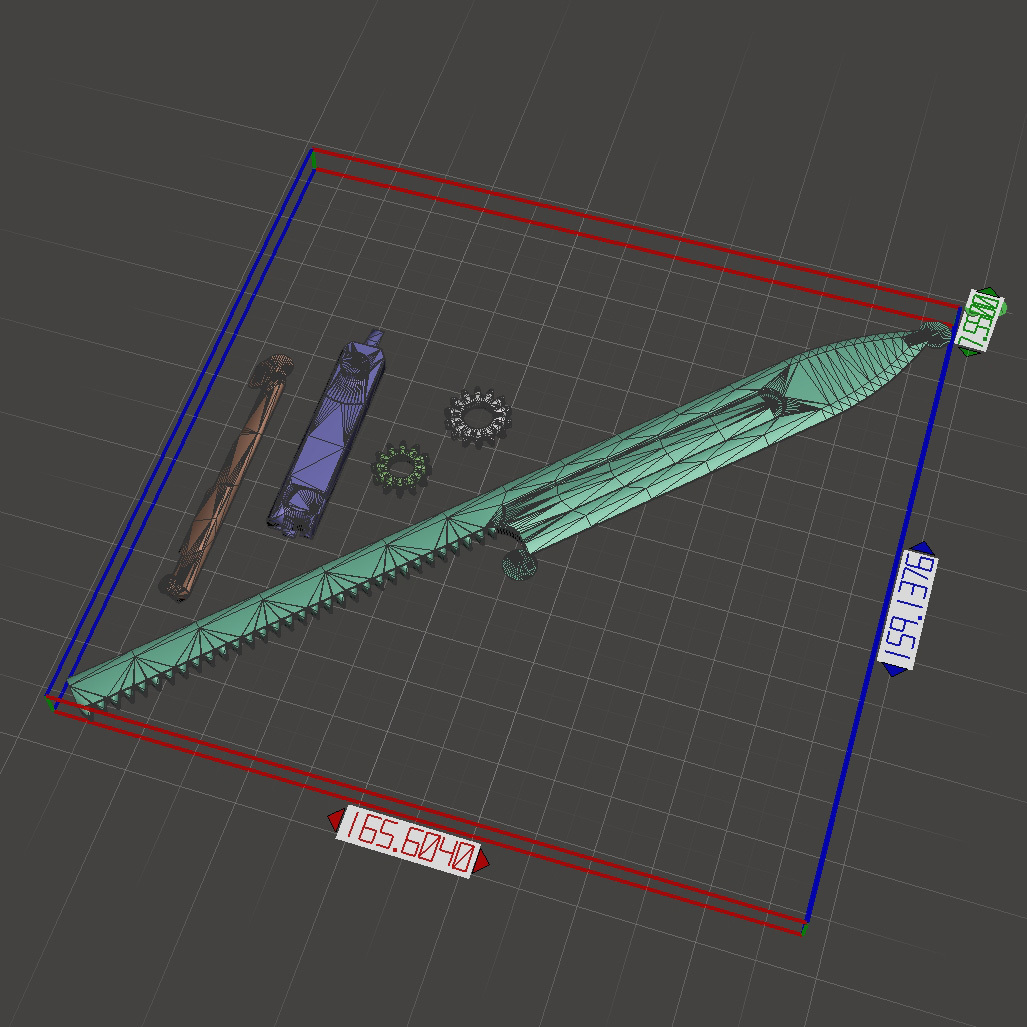

All the parts are ready to print and placed on a bed the most optimal way, taking into account layer arrangement and seam positions.

The files have embedded supports where required, but non-presupported files are also included.

Blade tip is rounded for safety reasons.

I'm going to stylize this model for other Assassin’s Creed game series later, you can subscribe my profile in order not to miss new versions.

IF SOMETHING DOESN’T WORK

The files were tested many times but unfortunately it doesn’t mean that they will work flawlessly with any 3D printer, because different printers can give different results at the same settings. I made a troubleshooting PDF guide that describes possible issues and their solutions and added it to the folder with printable files. Please read it first if you have any issues.

3D printing settings

UPD Oct.03.2023

There are 2 different versions of the mechanism.

The first one was made for PETG, it contains a 3D printed spring (the folder name is "Syndicate_Hidden_Blade_PETG").

The second version was made for PLA where a 3D printed spring was replaced with a piece of rubber band (acceptable thickness is 1.0-1.5mm), the folder name is "Syndicate_Hidden_Blade_PLA".

The main video instruction is dedicated to a PETG version, it shows all the process of 3D printing and assembly process step by step: https://youtu.be/v9SSSFaRpQI

It is also relevant to a PLA version, except for a rubber band related part, so I’ve made another video, just about this difference: https://youtu.be/mDPNlCua8GE

Layer height: 0.15mm

Wall line count: 3

Z seam position: at the back right corner

Top layers: 3

Bottom layers: 2

Infill density: 20-35%

Support generation: off

The overall 3D printing time is about 14 hours.

The minimal required bed size is 170*170 mm.

File formats: STL

The mesh was checked for errors.

Ring Size Conversion Chart

US ring size → diameter in mm (if it’s too tight try one step bigger size, if neither of them fits well please contact me)

4-½ → 15mm

4-¾ → 15.5mm

5 → 16mm

5-¼ → 16mm

5-½ → 16.5mm

5-¾ → 16.5mm

6 → 17mm

6-¼ → 17mm

6-½ → 17mm

6-¾ → 17.5mm

7 → 17.5mm

7-¼ → 18mm

7-½ → 18mm

7-¾ → 18.5mm

8 → 18.5mm

8-¼ → 18.5mm

8-½ → 19mm

8-¾ → 19mm

9 → 19mm

9-¼ → 19.5mm

9-½ → 19.5mm

9-¾ → 20mm

10 → 20mm

10-¼ → 20mm

10-½ → 20.5mm

10-¾ → 20.5mm

11 → 21mm

11-¼ → 21mm

11-½ → 21mm

11-¾ → 21.5mm

12 → 21.5mm

12-¼ → 22mm

12-½ → 22mm

12-¾ → 22.5mm

13 → 22.5mm

13-¼ → 23mm

13-½ → 23mm

13-¾ → 23mm

/https://fbi.cults3d.com/uploaders/24898590/illustration-file/73177805-d329-40f1-a158-9dc93ba299b7/Predator_Mask_Presentation.gif)

/https://fbi.cults3d.com/uploaders/24898590/illustration-file/34c4c8e4-fd9e-4ebb-b47e-642b9c6927ce/Pumpkin_Box_Animation.gif)