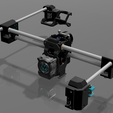

Retro-Glide V3

Full gantry upgrade.

So far, I'm able to have my max accelerations at 50k and my outer walls at 20k, on stock motors. Your results may vary depending on your setup, the accuracy of printed parts, and the materials used. Some of the testers have been able to achieve up to 100k.

My goal isn't speed; it's print quality, but the speed is a nice bonus, and damn is she fast.

This Gantry is based on V2.1 with additional upgrades.

V2.1 was designed to use all the original parts and pulleys of the OEM gantry.

V3 has been redesigned from the ground up and will require additional parts as it's based on getting the best parts for the job.

What's the Point?

The point of this gantry is to correct the skew and stiffness of the motion system, giving it the love it should have gotten from the factory. I have tried to make it as close as possible to the original gantry so you can use most of the original parts.

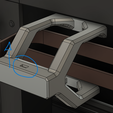

I have also moved the tensioners to the front, allowing for a better position on the back pulleys for better grip on the belts, allowing for better accelerations, and making it way easier to tension the belts with a lot more upgrades, such as the following.

Key Features

- Voron-like Front tensioners

- Stiffer and More Rigid Frame

- Cleaner Belt Path

- More Grip on Motor Gears

- Voron style Bearings F695 2rs for smoother movements

- Heat inserts for better mounting

- Customization

- Easy to print, designed with Printing in mind.

- Little to no support

- Supports speeds of up to 600mm/s @50k Acceleration on stock motors or more, depending on your setup.

- Fixes X rod twist

- CFS compatible

- CPAP compatible

- Uses original rods

- larger Build area coverage

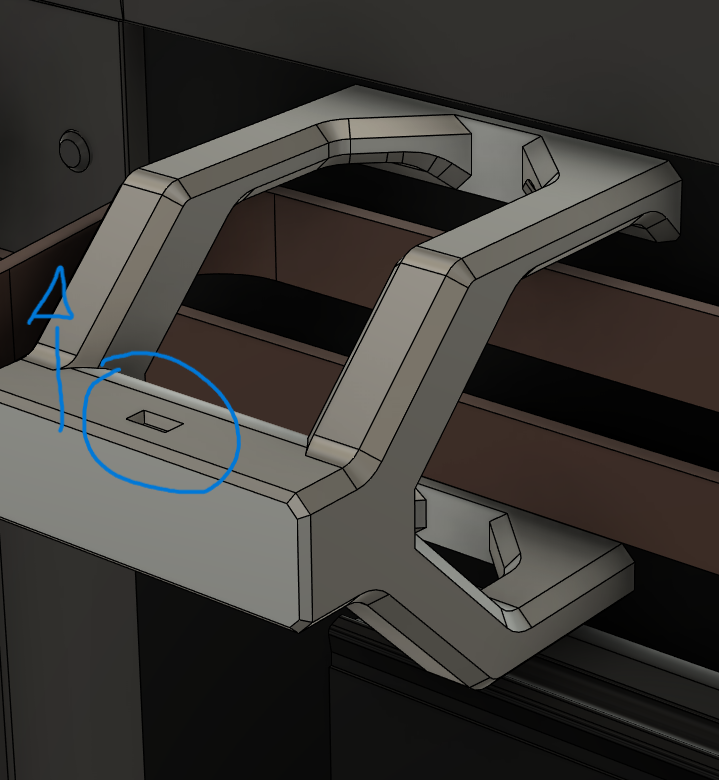

- Belt Tension Indicators for easy and accurate belt tensioning.

Importance of Clean Graphs?

The nice, clean graphs for input shapers allow you to push it further than the recommended accelerations, because you are starting from a clean base with no vibrations. The faster you go, the more it amplifies the vibrations. So if you start with low vibrations, by the time you max out the vibrations, it'll be way further than the recommended accelerations. So don't look at the recommended, look at the vibrations. See the added YouTube video for proof and added input shaper graphs.

If you don't know how to remove the top of the printer and access the gantry, please YouTube it first. It's pretty simple, and there are many videos on YouTube already. So take your time and do it properly.

Assembly and Installation Guide (Includes Links for Parts needed)

Materials needed:

Please see the Assembly and Installation Guide for BOM and Links to the ones I used.

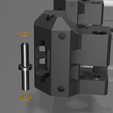

--Drill + 3mm Drill Bit for Removing thread in Pins Bore.

--2x All Metal M3 threaded Pins 30mm

Disclaimer

Use at your own risk. These have worked great for me and my K1 Max and K1. Please only do this mod if you know what you are doing.

I am not responsible for your mistakes

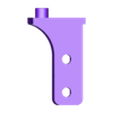

For K1C

The K1c has a new Door Hinge style, so you have to upgrade your Hinges with these Geared Hinges I remixed on Printables. It's free, but give the original Designer a follow for his hard work.

K1 Door Hinges

Added some extras.

- Tolerance Test. Holes should measure 10.15mm after printing. Or closest to it.

- Belt Clamps, in case you lose the original ones.

- CFS Cutter Trigger for K1c, K1se, K1 and K1 Max.

- Added .3mf file with color swap already done. Only 2 color swaps, so you can do it without a CFS/AMS.

Update: Added XY joints for 8mm rods as per request.

Update: Added Left motor mount with built-in Filament cutter trigger.

Update: Added Back Motor Mounts that take F695 2RS Bearings for the Double shear. since the original ones are hard to source.

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/481735df-c098-464f-8c7e-04d6086cbc4a/Screenshot-2025-07-11-121751.png)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/021a2eb6-7977-44a5-ac09-5b9dfdb8b971/IMG20230721114823.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/2b9f4e58-610b-41f7-89ab-f52e1ba4c880/IMG20240105223319.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/e4768ec0-6241-42ff-bea1-dc4b4bf044ef/1000015777.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/10164ce2-bc6c-477e-8043-94f02fef1417/IMG20240209232642.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/be1f54f6-16e3-4c45-b6d0-79272c06ab7c/20241017_224119.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/1afec3a5-ae64-4764-b5a1-2f4e71442d50/20241018_105806-1.jpg)

/https://fbi.cults3d.com/uploaders/29003947/illustration-file/3aaba5e4-c8b7-4575-a493-1ce39b00385f/20250504_122441.jpg)