CHANGELOG

2025-11-14 Increased the side clearance for the bottom cutout for the front right and front left parts.

2025-11-03 I was informed that Qidi has seen fit to move the entry position of the rear PTFE tube higher on the riser they using for the Qidi box. This may be to allow a more gradual curve of the tubes to the print head. I have modified the design to include a PTFE entry hole on the Rear Left part in the approximate location where Qidi place theirs on their riser. I have also included a rear left without a PTFE hole. For those who printed the part already - there is no need to reprint. I have included a zip with a drill guide template that you can use to make the PTFE hole. You will need a 5 mm drill bit (0.2 inch). A photo is included with the zip showing where to place the jig.

2025-10-26 Two new addons - Top mount TPU spool holder and Side mount build plate holders (see links in addons section below)

2025-10-22 Added revised instructions to explain how to install the anti-tilt pins, the rear glass stop and the rear spacer. Modified the glass stop to make it thicker and provide more clearance.

2025-10-12 Added missing front to front hex pegs (plate 11). Added option of rear spacer. There is an intentional indent at the rear of the riser on the ledge for the glass. In the next week or two I will be adding a folding lid handle addon. This will allow the glass lid to be propped up at the front a few centimeters. The notch/indent at the rear is to allow a backstop for the glass. If you do not wish to use this feature you optionally can mount the rear glass spacer as there is a slight gap in the glass at that point due to the notch / indent. Also, I am testing a corner filament guide that would mount on the rear left corner of the riser (as seen from the front). I should be available this week. The corner filament guide has a channel for a PTFE tube. If you mount the external spool holder on the left (when facing the printer) and the corner filament guide then you would have a PTFE tube that rounds the corner and connects directly to the printer PTFE feed.

2025-10-8 Modified the right and left lid holders to widen them and added a removeable glass stop that clips over the bar above the slit where the rear glass slides out of. They are available in the zip file "Lid Support V2 and Glass stop" and I added them to the updated print setting 2025-10-8

2025-10-7 Modified the build plate holders to add a little more width (12.5 mm 0.5 inch on each side) . I added them to the print setting 3mf file and also added a separate print setting 3mf file for these. They are version 2025-10-7

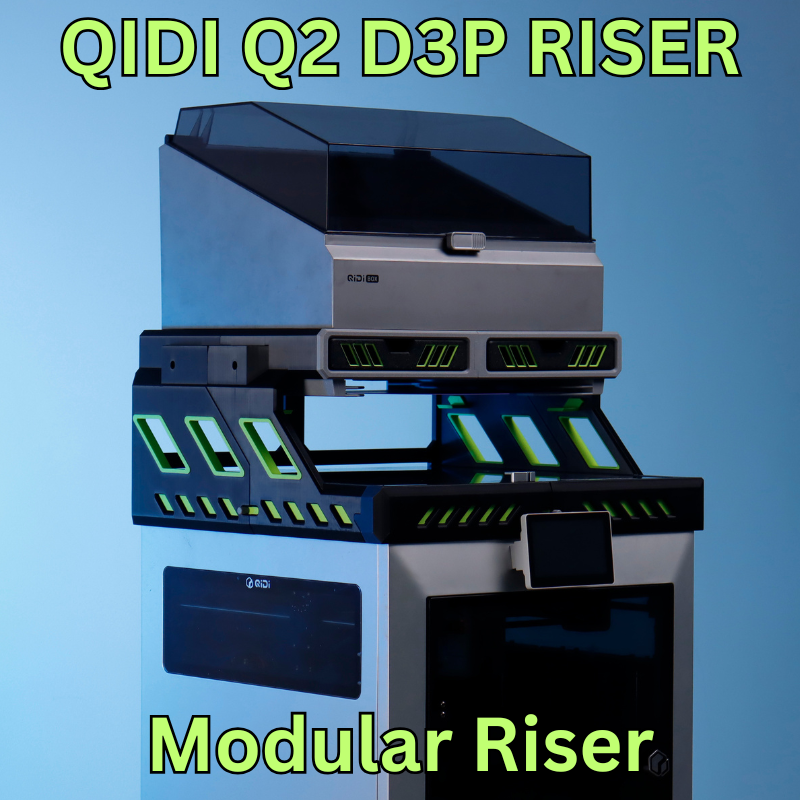

D3P RISER FOR THE QIDI Q2 by Darren 3d Print

Having designed a number of risers, I wanted one that offered it all, was modular for customization and also could be easily upgraded in the future. The result is my D3P riser system.

The D3P riser system is an innovative and modular riser system for your 3d printer. It features numerous free to download add-ons allowing you to customize your printer and riser like you want. The design of the D3P riser system is patent pending.

FEATURES

Features of the D3P riser system:

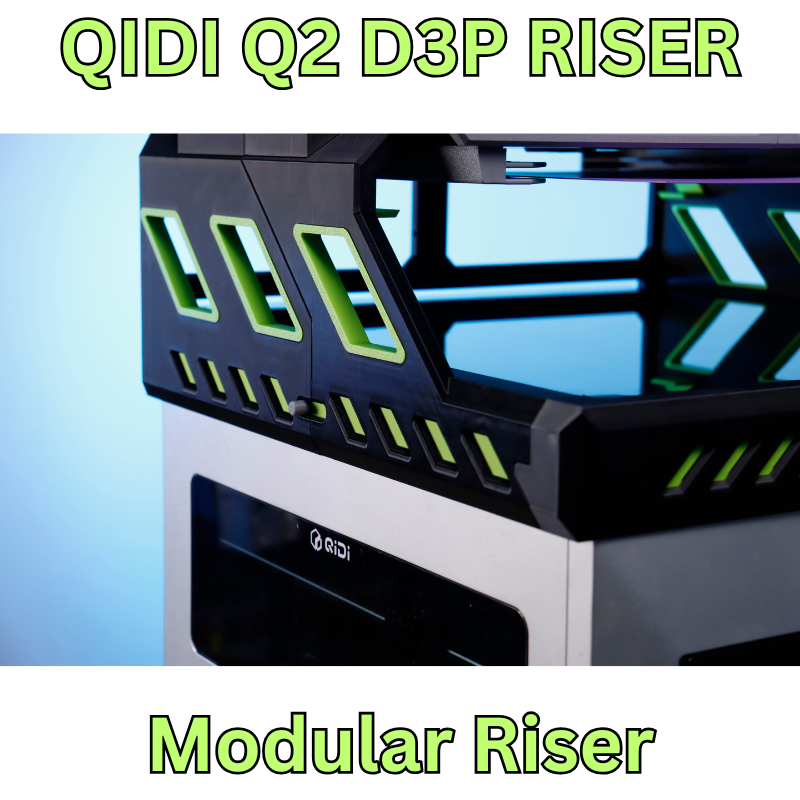

• Front and side adjustable vents;

• Add-on extensions for dual Qidi boxes units, single, dual and Quad dryers;

• Innovative COB LED channels that feature brackets to secure the LEDS in place;

• Top unit is set back to allow easy access to the printer from the top;

• Sturdy and reinforced construction and design to prevent sagging;

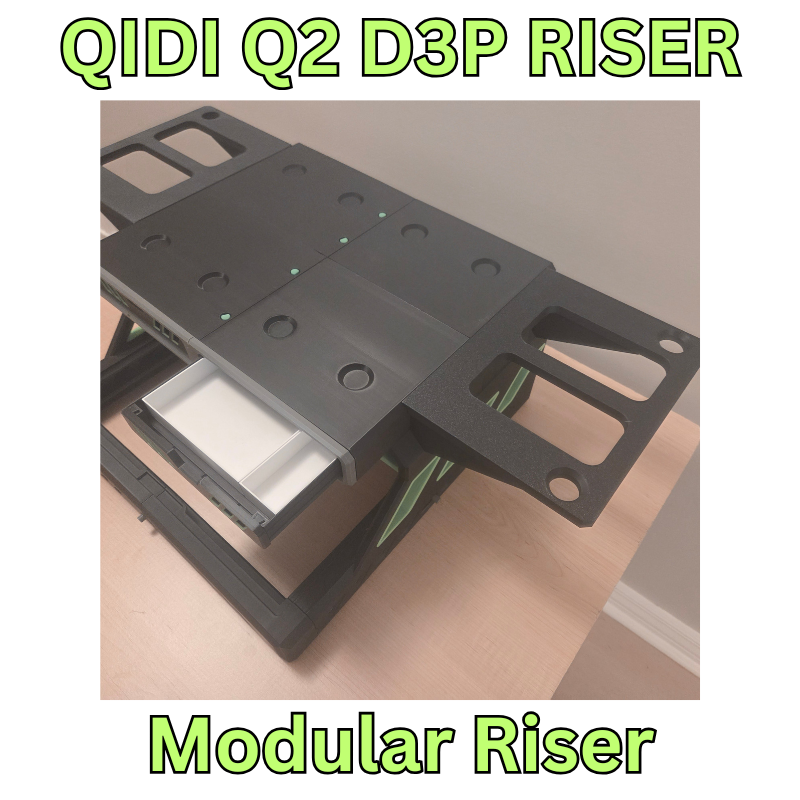

• Two large storage drawers with gridfinity style drawer inserts;

• Integrated build plate holder for two build plates;

• Integrated lid holders;

• Multiple add-ons such as a modular tool tray, interchangeable external spool holder and more to come;

• Detailed pdf instructions with pictures and steps;

• Printing requires little or no support.

A regular and a long drawer are included. The long drawer will require a larger printer but is optional.

INTELLECTUAL PROPERTY

This work is licensed under the standard digital file license. You are prohibited from sharing, sub-licensing, selling, renting, hosting, transferring, reproducing or distributing the digital file or 3d printed versions of this object, as well as any other derivative work in either digital or physical form (including remixes or copying/reproducing the design by any means).you are not allowed to use the objects in any manner that involves charging money or collecting fees without permission.

A patent has been filed for the D3P riser design and it is patent pending. I thank you for your understanding.

ADD-ONS

The model features a number of add-ons that are free to download. Be sure to bookmark this page as I will be adding to them.

NEWEST ADDONS

Top mount TPU spool holder: https://cults3d.com/en/3d-model/tool/tpu-top-mount-spool-holder-qidi-q2-d3p-riser

Side mount build plate holder: https://cults3d.com/en/3d-model/tool/side-mount-build-plate-holder-for-qidi-q2-d3p-riser

Folding lid handle: https://cults3d.com/en/3d-model/tool/folding-lid-handle-for-qidi-q2-d3p-riser

Corner filament guide: https://cults3d.com/en/3d-model/tool/corner-filament-guide-for-qidi-q2-d3p-riser

Single dryer shelf: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-single-dryer-shelf

Dual dryer shelf: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-dual-dryer-shelf

Quad dryer shelf: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-quad-dryer-shelf

Modular tool tray: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-modular-tool-tray

Interchangeable external spool holder: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-interchangeable-external-spool-holder

Drawer inserts: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-drawer-inserts

Dual Qidi Box extension shelves: https://cults3d.com/en/3d-model/tool/qidi-q2-d3p-riser-qidi-box-shelves

Glass lid anti-tilt pins: Print setting is included with this model. These are installed on the interior of the middle part where the square shaped cutout is. The pivot to allow the glass lid to be removed or to when extended over the lid they will prevent it tilting backwards. NOTE: These were added to the print setting version 2025-10-6 so no need to print these.

TECHNICAL SPECIFICATIONS

For the base riser:

Filament: 2.7 kg

Approximate print time: 3 days 6h

Height of riser: 20 cm (8 inches) approx

Height of riser and Qidi box unit: 43.5 cm (17 inches)

PRINT SETTINGS

IMPORTANT I upload a print setting files for all my models. The print settings has the parts positioned for correct printing.

EACH BUILD PLATE HAS THE TYPE OF SUPPORT REQUIRED INDICATED ON THE BUILD PLATE DESCRIPTION (TREE AUTO, TREE MANUAL OR NO SUPPORT).

I strongly recommended you use my print setting file. If not, I will not be able to assist you if there is an issue when printing. From experience, many of the issues with printing my models are on account of users not using my print settings.

IMPORTANT: I was informed that Qidi has seen fit to move the entry position of the rear PTFE tube higher on the riser they using for the Qidi box. This may be to allow a more gradual curve of the tubes to the print head. I have modified the design to include a PTFE entry hole on the Rear Left part in the approximate location where Qidi place theirs on their riser. I have also included a rear left without a PTFE hole. For those who printed the part already - there is no need to reprint. I have included a zip with a drill guide template that you can use to make the PTFE hole. You will need a 5 mm drill bit (0.2 inch). A photo is included with the zip showing where to place the jig.

CHANGELOG

If there are any changes to the STL files or print settings I will list them here. I recommend looking at this section prior to printing as it is the only way I can inform users of changes.

3D PRINT SETTINGS

I use the following settings and materials to print this model:

Infill % : 15% (no need for more)

Nozzle diameter: 0.4 mm

Layer height: 0.2 mm standard

Material: I am often asked the question about the riser deforming when using PLA when printing ABS or ASA. I prefer PLA since it cheaper to purchase and easier to print. I print all my risers in PLA but I seldom print in ASA or ABS. I have some users that printed in PETG and some in ABS. Both will also work providing your printer can maintain tolerances. PETG may be preferable if you intend on printing higher temp materials. PETG-CF has a slightly higher melting point than PETG so this may also be considered.

ASSEMBLY AND INSTRUCTIONS

A detailed instruction and assembly guide with steps and pictures is available for download with the model files.

TROUBLESHOOTING

All parts and the assembly have been tested multiple times (both printing and assembly).

• Make sure your build properly cleaned and free of grease and oils before printing. This is the cause of adhesion.

• Make sure you use my print profiles/settings (the .3mf file that has multiple plates with all the parts) and that you enable support as indicated for each build plate on the build plate description.

• Filament and printer will affect tolerances however all should fit. If unsure proceed slowly and cautiously.

• If there are any changes I list them in a changelog on the model page. Please have a look at it prior to printing in the event there are any changes.

I am available to assist with any issues with this model.

The best way to reach me is through Facebook messenger – my user name is “Darren 3d print”.

I thank you for your support and hope you like this model.

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/2fef9f7f-8285-42c3-b697-bbbf9dee5947/qb1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/65a6625f-61ee-46aa-8a7f-2c3894eac922/di2.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/b4442f6c-509a-42c0-aaa8-3db767fea49b/dd1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/79d60eb9-81aa-49e8-9b60-dc766a645b2d/es1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/ad51d36b-65cf-4745-9c7a-b7cf5132c67a/mtt1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/15b0c336-cafe-4831-9f66-55f729d1e9a2/qd1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/4cc62fb5-b98d-4903-b9b3-005304128ad8/sd1.png)

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/50b77a7b-4813-4f1d-b8e6-e9f77ee8351f/f1.png)