D3P RISER FOR BAMBU LAB P1S by Darren 3d Print

This riser is for the P1S. It is not a perfect fit for the new P2S. I have a separate riser for the P2S here: https://cults3d.com/en/3d-model/tool/d3p-riser-for-bambu-lab-p2s

CHANGELOG

2025-11-18 Modified the front left part for the Panda touch to adjust the angle of the Panda touch to allow more clearance and added holes for 4 screws.

2025-11-8 Added a cutout on the bottom of the Front right part for the V2 Tall version to pass the Panda Touch cable. The rest is unchanged.

NEW 2025-11-8 - Added a V2 Tall version of the riser. The riser is pretty much identical to the original V1 riser but I added 18 mm (3/4 inch) of height for greater clearance and access (see details below in the V1 vs V2 section)

NEW 2025-11-7: Added a Front left part for Panda BigTree Touch. (see details in the Panda touch section below)

Note: The model is also available on Creality Cloud should you not be able to purchase it on Cults: https://www.crealitycloud.com/model-detail/d3p-riser-bambu-lab-p1s?source=22

D3P RISER

Having designed a number of risers, I wanted one that offered it all, was modular for customization and also could be easily upgraded in the future. The result is my D3P riser system.

The D3P riser system is an innovative and modular riser system for your 3d printer. It features numerous free to download add-ons allowing you to customize your printer and riser like you want. The design of the D3P riser system is patent pending.

FEATURES

Features of the D3P riser system:

• Front and side adjustable vents;

• Add-on extensions for dual AMS 1 or AMS 2 units;

• Innovative COB LED channels that feature brackets to secure the LEDS in place;

• Top unit is set back to allow easy access to the printer from the top;

• Sturdy and reinforced construction and design to prevent sagging;

• Foldable add-on lid handle to prop the lid open;

• Two large storage drawers with gridfinity style drawer inserts;

• Integrated build plate holder for two build plates;

• Integrated lid holders;

• Opening on inner front for sd card access;

• Multiple add-ons such as a modular tool tray, interchangeable external spool holder and more to come;

• Detailed pdf instructions with pictures and steps;

• Printing requires little or no support.

• Optional Panda Touch magnetic base stand (see Panda Touch below).

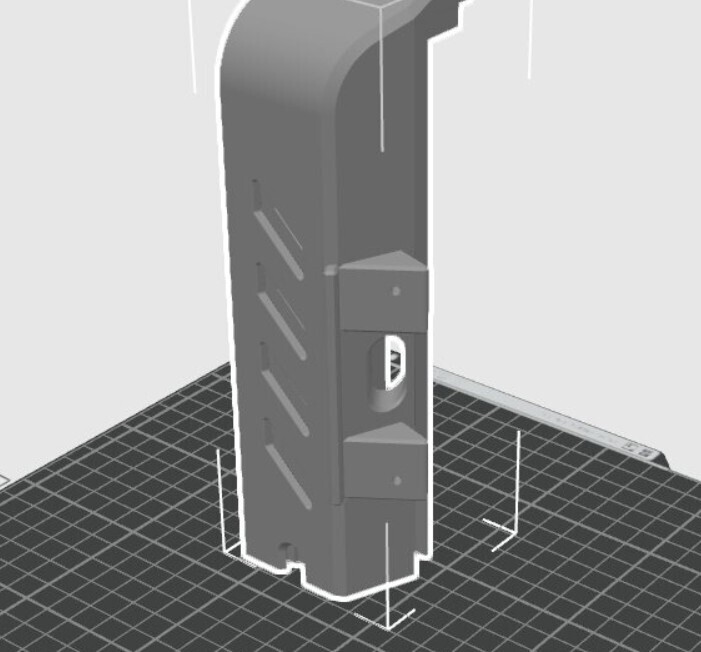

VERSION 1 VS VERSION 2

There are now two options to choose from. The original V1 riser and the V2 (you can see the difference in the 2nd photo). V1 files are unchanged.

The V2 is 18 mm (3/4 inch taller) but has the same features as V1. All addons work with both version

There are two packages zip files. One for V1 and one for V2. Select the one you want. If you are not certain, I would suggest the V2 as the added clearance is very nice to have.

If you wish to upgrade you will need to reprint the parts except for the following: Side inserts and the drawers. The others may not be compatible.

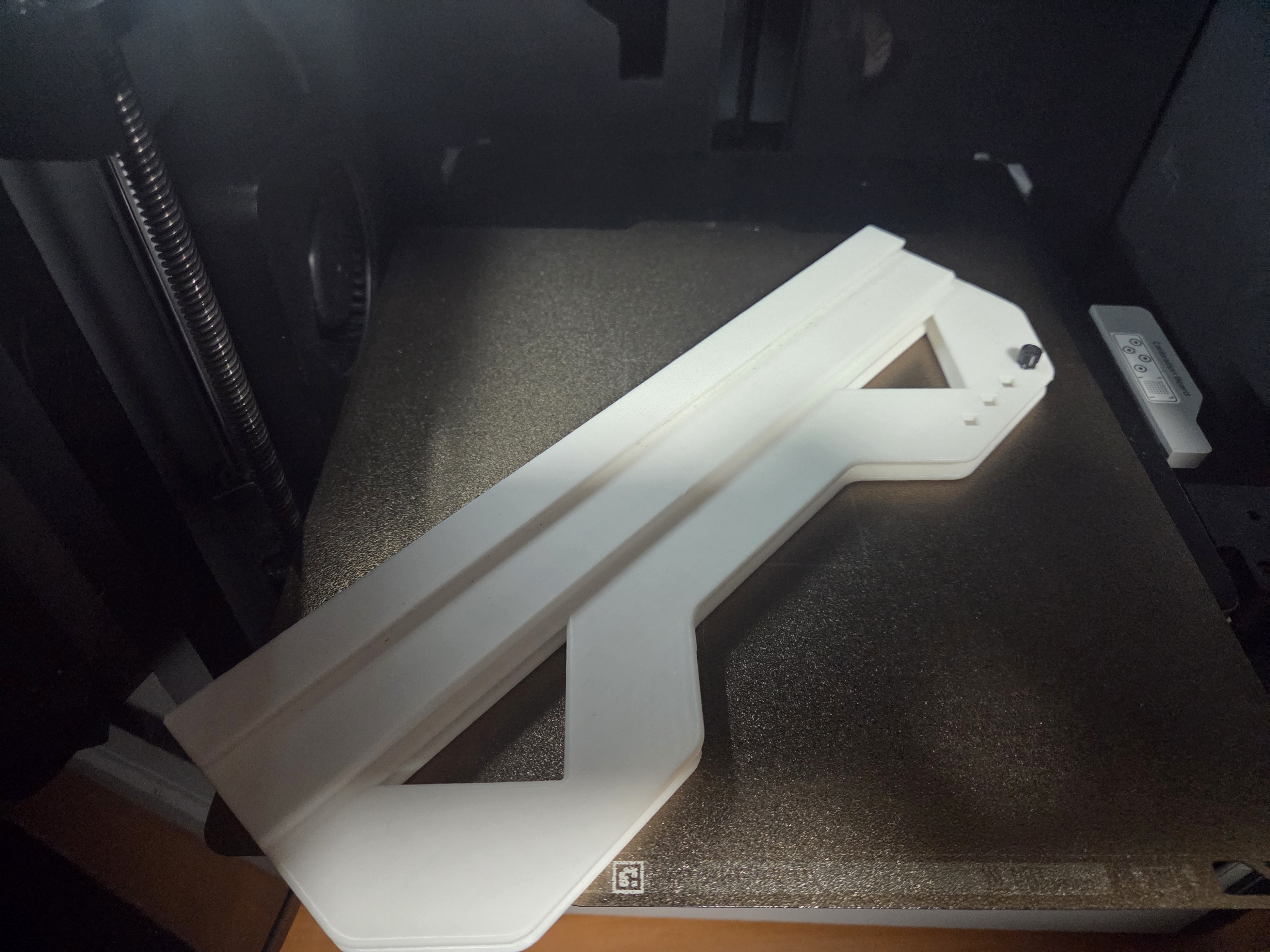

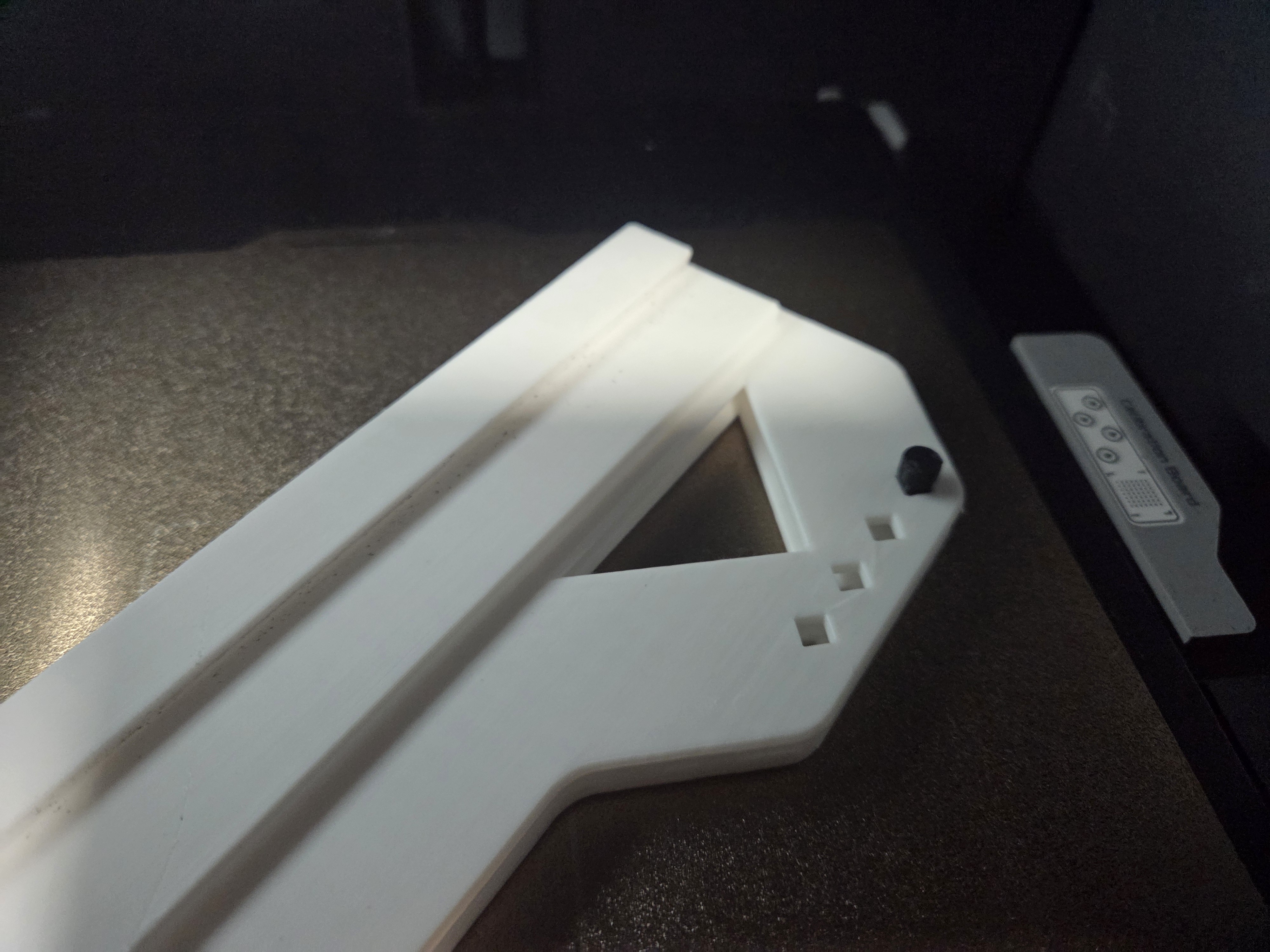

PANDA TOUCH

Each riser package (V1 and V2) contains a Panda touch option (see photo 3).

IMPORTANT: If you want the Panda Touch option do not print the stock Front Left part as it is replaced. Also each of V1 and V2 have a separate Panda Touch mod and these are not interchangeable.

The Front left part now has a mount for the Magnetic charging dock and dispenses with the Mounting Bracket. It also features a cutout to pass the cable to connect a USB cable to the Magnetic charging dock. You will need to supply two small screws to mount the Magnetic charging dock to the Front left part. I do not have the Panda Touch system and I am working off STL supplied by Panda. I would appreciate feedback and some slight adjustments may be made based on the feedback.

INTELLECTUAL PROPERTY

This work is licensed under the standard digital file license. You are prohibited from sharing, sub-licensing, selling, renting, hosting, transferring, reproducing or distributing the digital file or 3d printed versions of this object, as well as any other derivative work in either digital or physical form (including remixes or copying/reproducting the design by any means).you are not allowed to use the objects in any manner that involves charging money or collecting fees without permission.

A patent has been filed for the D3P riser design and it is patent pending. I thank you for your understanding.

ADD-ONS

The model features a number of add-ons that are free to download on MakerWorld. All addons work with V1 and V2 of the riser.

Panda Touch mod - included in each V1 and V2 riser package.

Side mounted build plate holder: https://makerworld.com/en/models/1921176-x1c-p1s-p2s-d3p-side-build-plate-holder#profileId-2061434

AMS-HT Side shelf: https://makerworld.com/en/models/1786413-ams-ht-side-shelf-for-x1c-p1s-d3p-riser#profileId-1903530

TPU top mount spool holder:

https://makerworld.com/en/models/1688255-tpu-top-mount-spool-holder-p1-and-x1c-d3p-riser#profileId-1789303

Drawer inserts:

https://makerworld.com/en/models/1260535-drawer-inserts-for-dual-ams-sidekick-stand#profileId-1284915

Interchangeable spool holder:

https://makerworld.com/en/models/1636867-interchangeable-spool-holder-for-d3p-riser#profileId-1729260

Lid handle:

https://makerworld.com/en/models/1636856-lid-handle-for-x-c-and-p1s-d3p-riser#profileId-1729242

Modular tool tray:

https://makerworld.com/en/models/1636862-modular-tool-tray-for-x1c-and-p1s-d3p-riser#profileId-1729251

AMS 1 and AMS 2 shelf extensions:

https://makerworld.com/en/models/1636838-ams-shelf-extension-for-x-c-p1s-d3p-riser#profileId-1729228

AMS HT - Single dryer extension shelf:

https://makerworld.com/en/models/1752986-ams-ht-extension-shelf-for-the-d3p-riser#profileId-1863869

I will be adding to these so be sure to check back from time to time.

TECHNICAL SPECIFICATIONS

For the base riser:

Filament: 2.6 kg

Approximate print time: 3 days 4h

V2 takes a little longer and requires a little more filament but not much.

V1:

Height with closed AMS unit: 86 cm (34 inches)

Height with open AMS unit: 101 cm (40 inches)

v2

Height with closed AMS unit: approximately 104 cm (34.75 inches)

Height with open AMS unit: approximately 119 cm (40.75 inches)

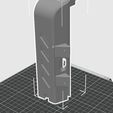

PRINT SETTINGS

IMPORTANT I upload a print setting files for all my models. The print settings has the parts positioned for correct printing.

EACH BUILD PLATE HAS THE TYPE OF SUPPORT REQUIRED INDICATED ON THE BUILD PLATE DESCRIPTION (TREE AUTO, TREE MANUAL OR NO SUPPORT).

I strongly recommended you use my print setting file. If not, I will not be able to assist you if there is an issue when printing. From experience, many of the issues with printing my models are on account of users not using my print settings.

CHANGELOG

If there are any changes to the STL files or print settings I will list them here. I recommend looking at this section prior to printing as it is the only way I can inform users of changes.

3D PRINT SETTINGS

I use the following settings and materials to print this model:

Infill % : 15% (no need for more)

Nozzle diameter: 0.4 mm

Layer height: 0.2 mm standard

Material: I am often asked the question about the riser deforming when using PLA when printing ABS or ASA. I prefer PLA since it cheaper to purchase and easier to print. I print all my risers in PLA but I seldom print in ASA or ABS. I have some users that printed in PETG and some in ABS. Both will also work providing your printer can maintain tolerances. PETG may be preferable if you intend on printing higher temp materials on a regular basis.

ASSEMBLY AND INSTRUCTIONS

A detailed instruction and assembly guide with steps and pictures is available for download with the model files.

Have a look at MkesQuestLog assembly video for the riser:

https://www.youtube.com/shorts/gCheKPiknRc

TROUBLESHOOTING

All parts and the assembly have been tested multiple times (both printing and assembly).

• Make sure your build properly cleaned and free of grease and oils before printing. This is the cause of adhesion.

• Make sure you use my print profiles/settings (the .3mf file that has multiple plates with all the parts) and that you enable support as indicated for each build plate on the build plate description.

• Filament and printer will affect tolerances however all should fit. If unsure proceed slowly and cautiously.

• If there are any changes I list them in a changelog on the model page. Please have a look at it prior to printing in the event there are any changes.

I am available to assist with any issues with this model.

The best way to reach me is through Facebook messenger – my user name is “Darren 3d print”.

I thank you for your support and hope you like this model.

/https://fbi.cults3d.com/uploaders/15758717/illustration-file/db1db915-4d72-406c-908b-1c24d9daba61/h3.png)