3D model description

If there is interest, I can modify and redraw the design into any desired shape – such as a triangle, circle, hexagon, or similar. Creating a more rounded version is no problem....

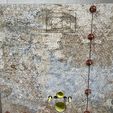

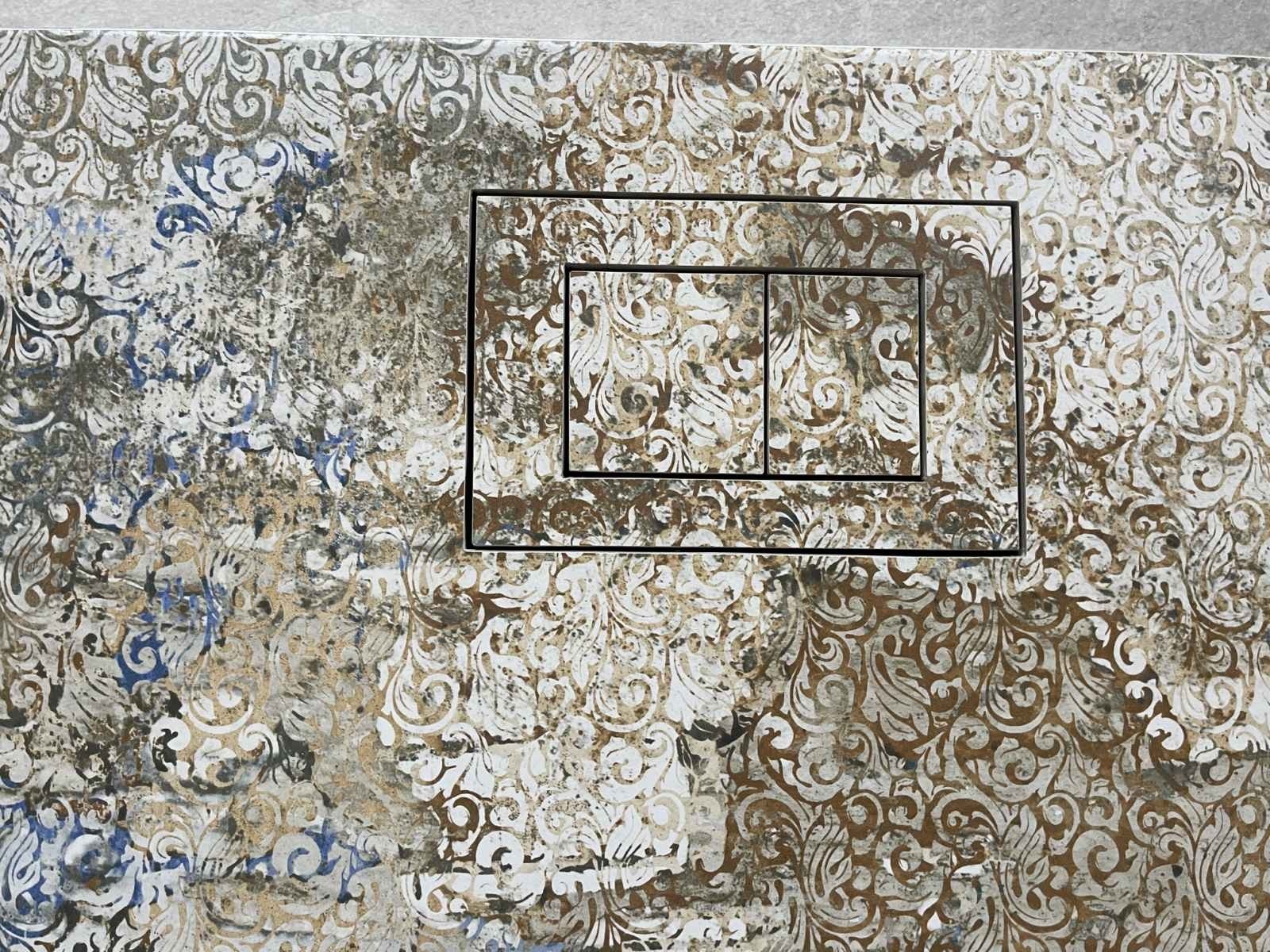

Integrated flush system for Geberit

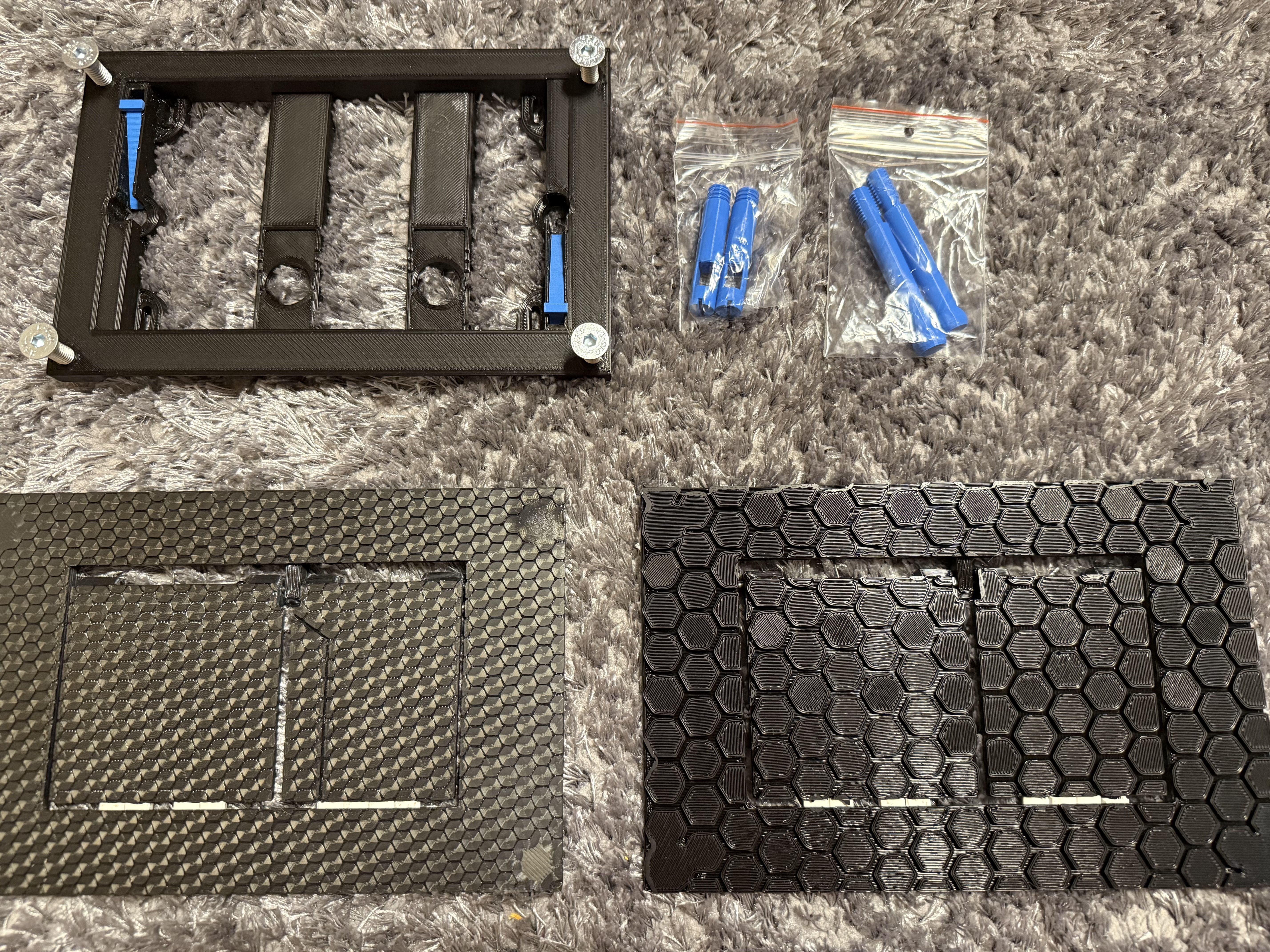

Using four magnets (⌀18 mm × 2 mm), polished 3 mm steel rods, and four M8 flat-head screws, you can create a luxurious and stylish design for your Geberit flush plate. This solution is functional, elegant, and perfectly suited for modern bathroom interiors.

Installation Procedure

This product is designed for the simple and precise installation of a designer flush plate directly onto a tiled surface. It is fully compatible with built-in (concealed) installation modules from the Geberit brand. The product is intended for professional installation by a qualified specialist with the necessary technical knowledge and experience required to modify and accurately mount the control element. The entire process ensures minimal interference with the existing concealed system while maintaining its functionality and aesthetics.

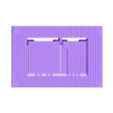

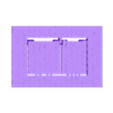

Basic Dimensions:

Height: 155 mm

Width: 240 mm

Detailed dimensions and a 1:1 scale technical drawing are attached.

Installation Parameters:

The minimum installation depth is 27 mm from the tile and adhesive edge, or 37 mm when using 10 mm tiles with epoxy adhesive.

When bonding the tile to the upper part of the flush plate, follow these steps:

1. The tile must be made of polished stone, fired ceramic, wood, tempered glass, or metal with precise dimensions: 240 × 155 × 3–7 mm.

2. The surface of the tile must be thoroughly cleaned and dry. The rear side must be degreased and properly cleaned.

3. Use a vinylester-based two-component adhesive such as: Superior V‑Max SV‑9 - Pearl - Gold (Vinyl Ester) / K Bond Vivid / Icon Knife Grade / Tenax Titanium / Polyvinyl types (CT1, MS polymer) Mamut .

4. For bonding the main tile frame to the flush plate, use clamping clips (do NOT use spring clips!). Ensure accuracy and high bonding quality. Carefully align and adhere the frame to the back of the tile – precise flush fitting is essential. Maintain pressure with clips for at least 45 minutes at 20 °C to allow for sufficient adhesion. Note: drying time may vary depending on the surrounding temperature and the adhesive used.

5. Once fully cured, remove the clips. Snap the buttons in place so that the top edge aligns flush with the frame.

6. Then slide the top part of the plate onto the bottom part.

7. Final alignment is achieved by adjusting the corner screws of the mounting frame (M10 Allen screws).

8. If the plate is not properly aligned or sits unevenly, repeat step

9. Sound of falling water: :D

Please, after purchasing, send me an email so that I can send you the manual/template.

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/7684a621-85dd-40cd-8f99-7c64e651f35f/IMG_6462.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/35a38e51-4bd9-4ba2-8709-853a30612868/IMG_8739.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/fe753461-44f5-4bf7-ba8a-40a48a69cfa5/IMG_9236.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/3fa2008d-1fc3-4b29-accb-0b01de478705/IMG_0723.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/93a484da-5fb4-44d6-b731-70d2bf99cfeb/IMG_0723.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/be55155f-a4ad-4c7c-aaac-c4932a914f74/IMG_0770.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/63eeaef1-8807-4f3f-b369-4a0f3b91f043/IMG_8744.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/3db870b5-888c-4aec-b399-a9742f101f60/IMG_8791.jpg)

/https://fbi.cults3d.com/uploaders/14625050/illustration-file/cb5ab646-c754-4e64-8762-27cec8c61ad3/pf2024.png)