3D model description

Create your own unique, irregular honeycomb candles with this easy-to-use 3D printable kit!

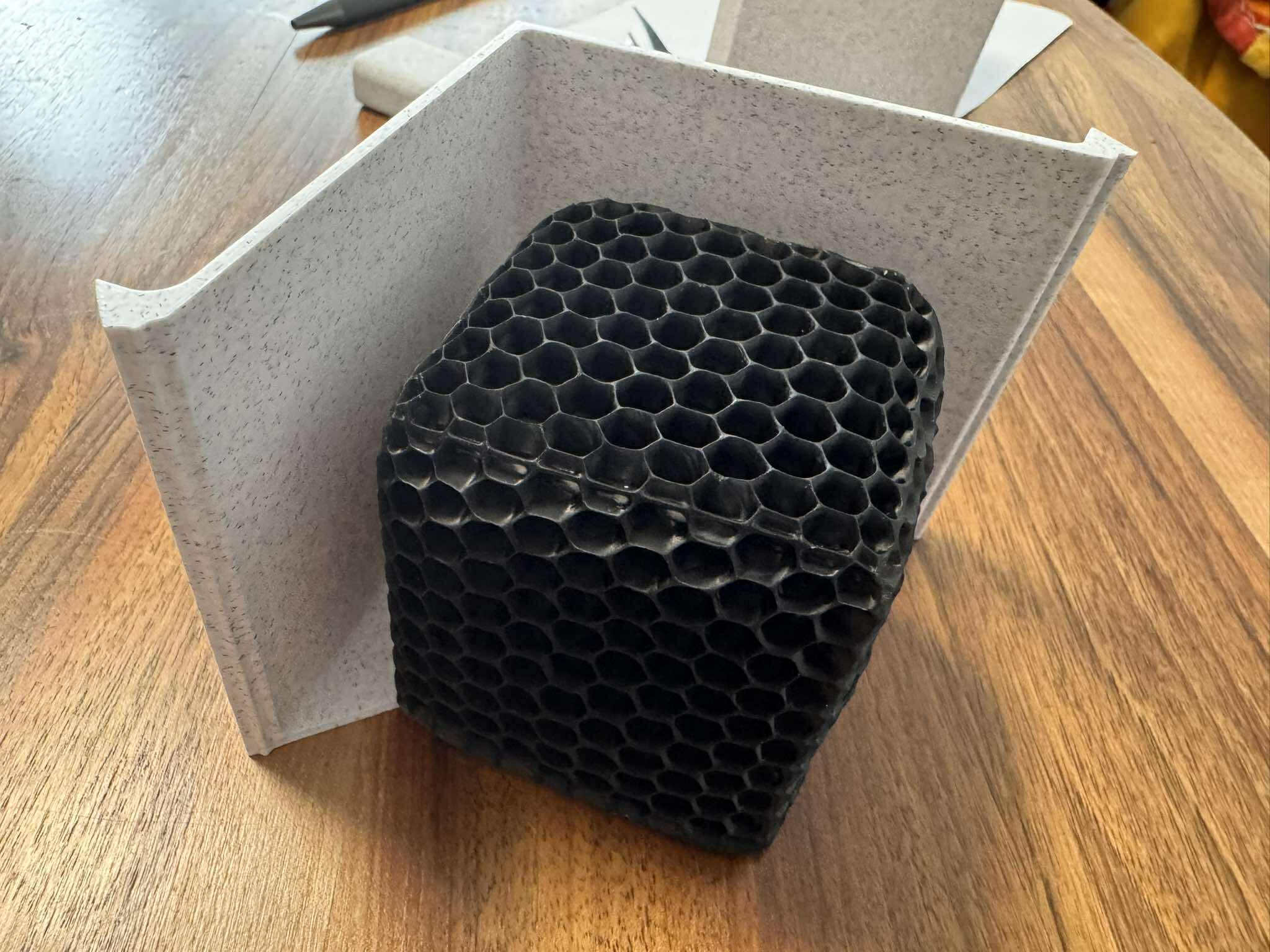

This model is designed for DIY enthusiasts and candle makers who want to create a highly detailed silicone mold. The final result is a beautiful, rustic candle with a naturally rough, irregular honeycomb texture.

📦 What's Included?

1x Honeycomb Master Positive (DLP Recommended): The positive model of the candle (an irregular cube with honeycomb texture). It is designed to be printed with a Resin/DLP/SLA printer to capture the intricate, fine honeycomb detail and ensure the smoothest possible finish for your silicone mold.

1x Casting Box Half (FDM Friendly): This file represents one half of the reusable outer shell (box).

1x Locking Clip (FDM Friendly): This file represents one of the clips used to secure the box halves.

🛠️ Assembly & Silicone Casting Instructions

Assembly: Place the Master Positive model inside one of the Casting Box Halves.

Close & Secure: Place the second Casting Box Half over the Master Positive to close the box.

Lock: Use the two Locking Clips to snap the box halves securely together. The Master Positive should now be firmly suspended in the center.

Seal (Crucial!): Since the box is reusable and clips together, you must ensure the seam between the two halves and the base is perfectly sealed before pouring. Use masking tape or duck tape to cover all seams completely to prevent liquid silicone leaks.

Pouring & Curing: Mix your silicone and pour it in. Once cured, remove the tape and clips, separate the box halves, and carefully demold your new silicone candle mold!

The reusable, clip-together design of the FDM-printed Casting Box makes the mold-making process efficient and saves material!

3D printing settings

To ensure a high-quality silicone mold, the two parts of this kit should be printed with different goals in mind: precision for the Master Positive and speed/durability for the Casting Box.

- Honeycomb Master Positive (High Detail)

This part needs to be as smooth as possible to capture the fine honeycomb texture.

Recommended Printer: DLP/SLA Resin Printer (Highly Recommended)

Material: Standard Resin (e.g., Grey, Clear)

Layer Height: 0.05 mm or lower for the best detail.

Hollowing: Printing the Master Positive hollow is highly recommended to save on resin material. When adding drainage, it is recommended to place the drainage hole slightly smaller than the square on the bottom face of the master model.

Orientation: Print at an angle to minimize visible layer lines on the main surface.

Post-Processing: Curing and a light sanding/polishing of the visible surface is recommended to ensure the absolute smoothest finish for the silicone mold.

- Casting Box Halves & Locking Clips (FDM / Reusable Parts)

These parts prioritize structural integrity and speed, as surface finish is not critical.

Recommended Printer: FDM Printer

Material: PLA or PETG

Infill: 15–20% (e.g., Cubic or Grid)

Perimeters (Wall Thickness): 3 to 4 for sturdiness.

Layer Height: 0.2 mm – 0.3 mm (for faster printing).

Quantity: Print the Casting_Box_Half.stl and Locking_Clip.stl files twice (2x) each.

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/21cb1353-73f3-4751-90e8-9c3f5584a820/0-02-05-922e5a628b509f9c537c2e6cc346e56c734a63aa0aaaeee566e5b42b9df750bf_5b7b6e8f19724c09.jpg)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/ba80ab88-3585-4b3a-b738-10668a71e9b2/Screenshot_1.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/a3d80521-a691-4707-a575-3549bc0001e5/Screenshot_2.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/56e87fe4-7d1e-4eb8-aff3-8b4ad8b6339c/Screenshot_1.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/fa0e188e-a810-4234-86ca-4e9d8945ce75/Screenshot_1.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/2c4f5607-10d3-4775-acad-fdd5a8a62401/Screenshot_2.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/218d086b-0562-410a-8f47-af08a555aeb2/Screenshot_1.png)

/https://fbi.cults3d.com/uploaders/20409961/illustration-file/dc11a598-c664-4565-8757-0f7c9326bc42/Screenshot_21.png)