3D model description

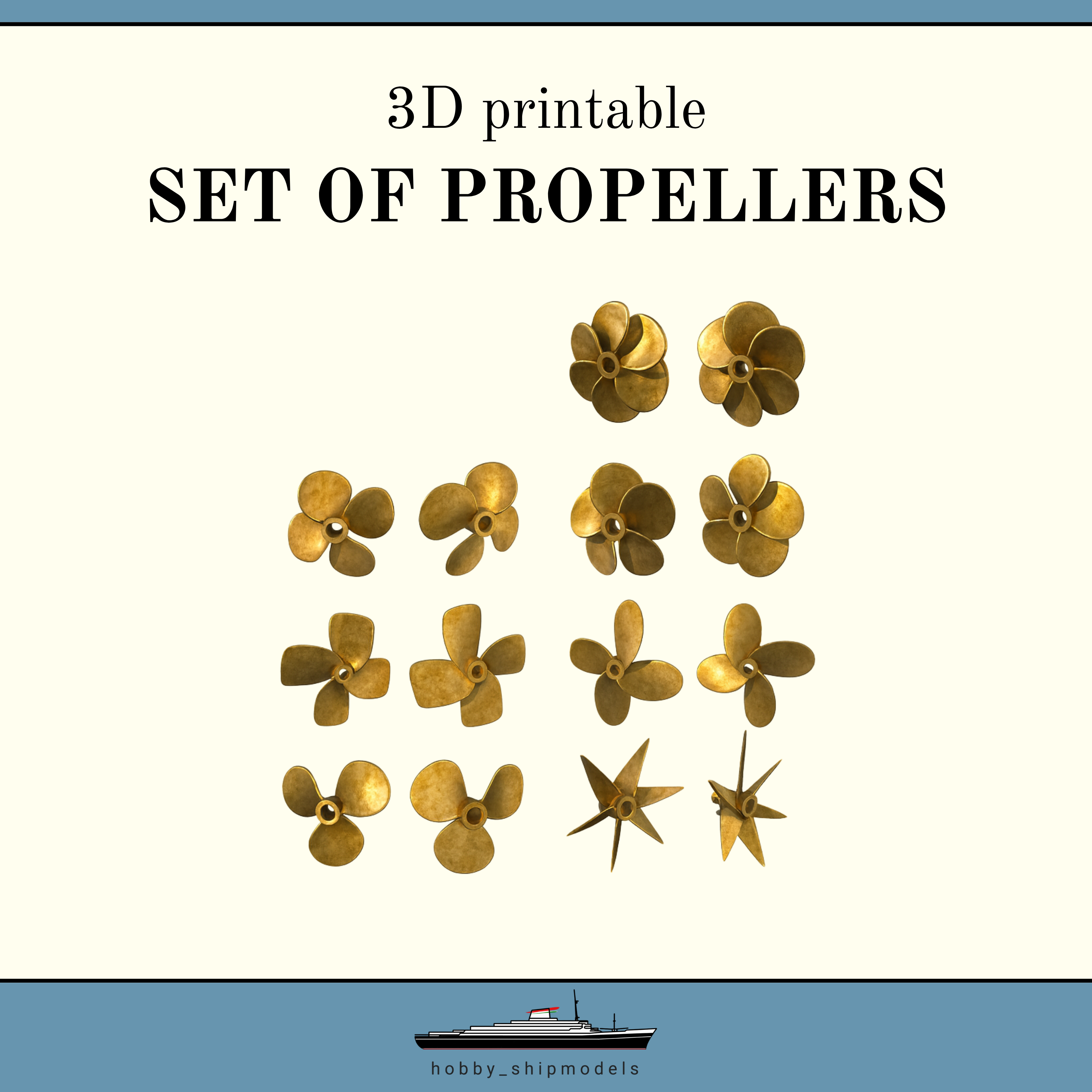

This STL bundle includes 7 pairs of 3D printable propellers, designed for different types of RC boats and propulsion setups. It covers a wide variety of configurations suitable for various model applications.

Each pair is described below:

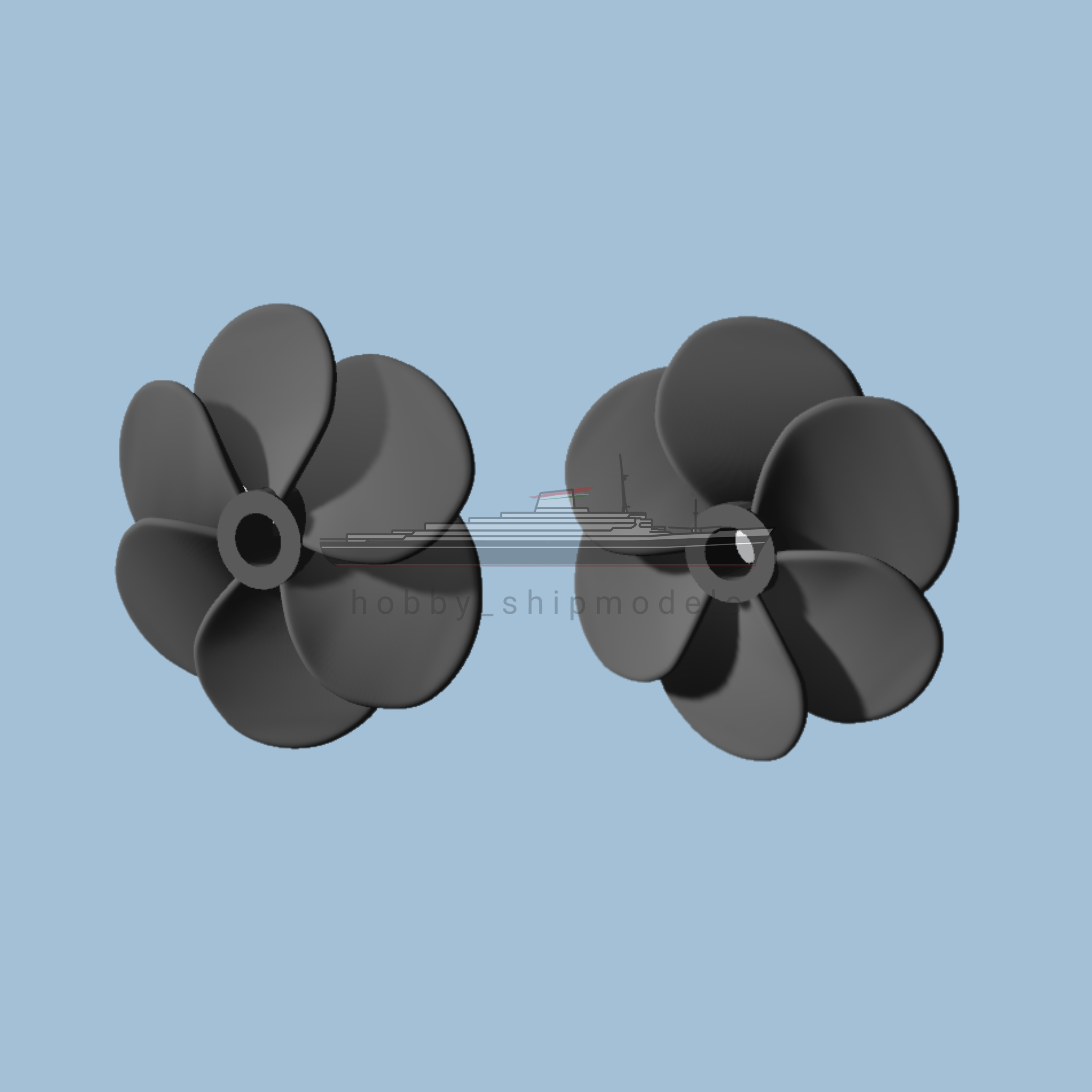

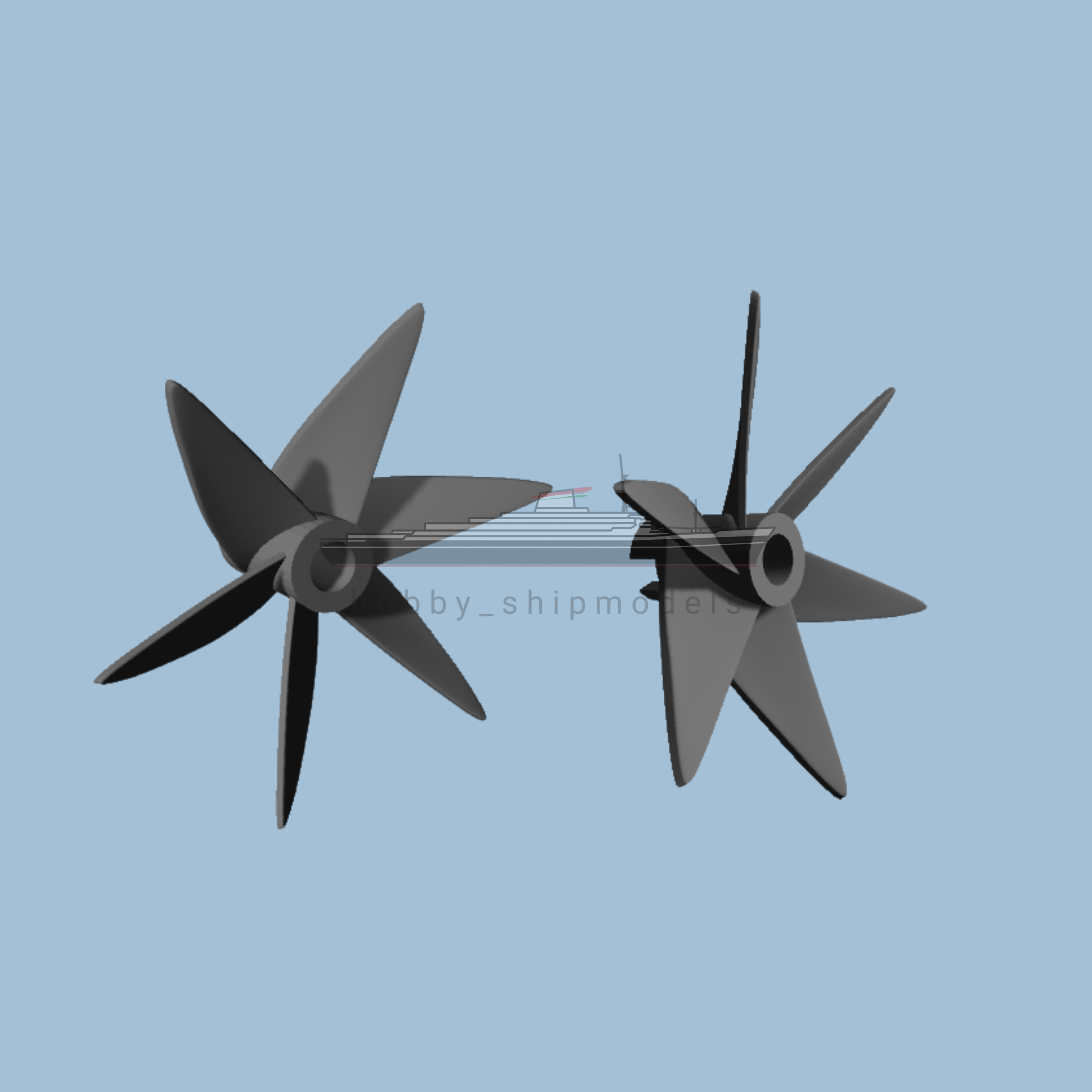

- 6-blade propeller pair

Designed for twin-shaft displacement yachts or leisure vessels. Commonly used on larger-scale RC models with traditional shaft lines.

- 5-blade propeller pair

Also intended for displacement model vessels with dual-shaft setups, such as yachts and classic boats.

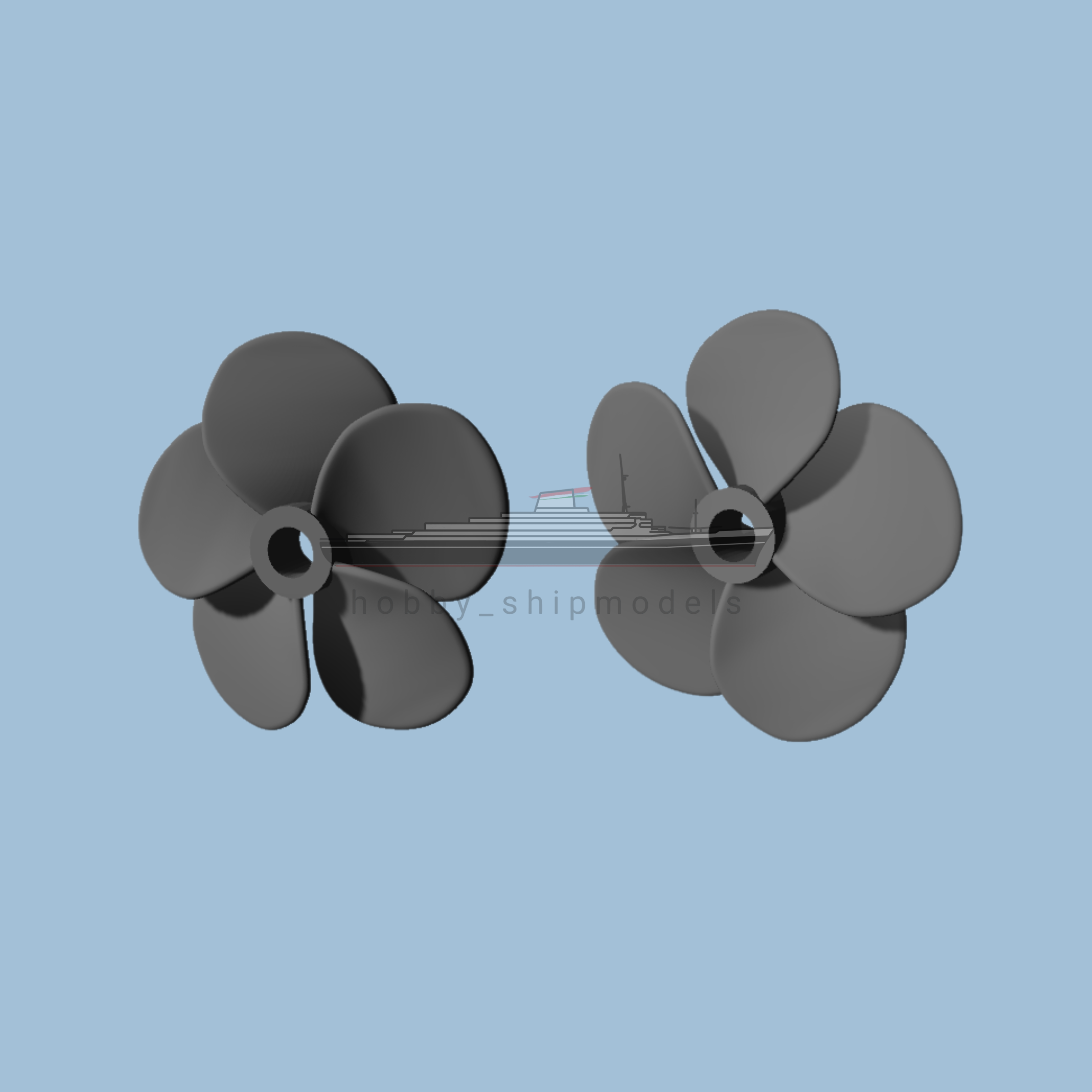

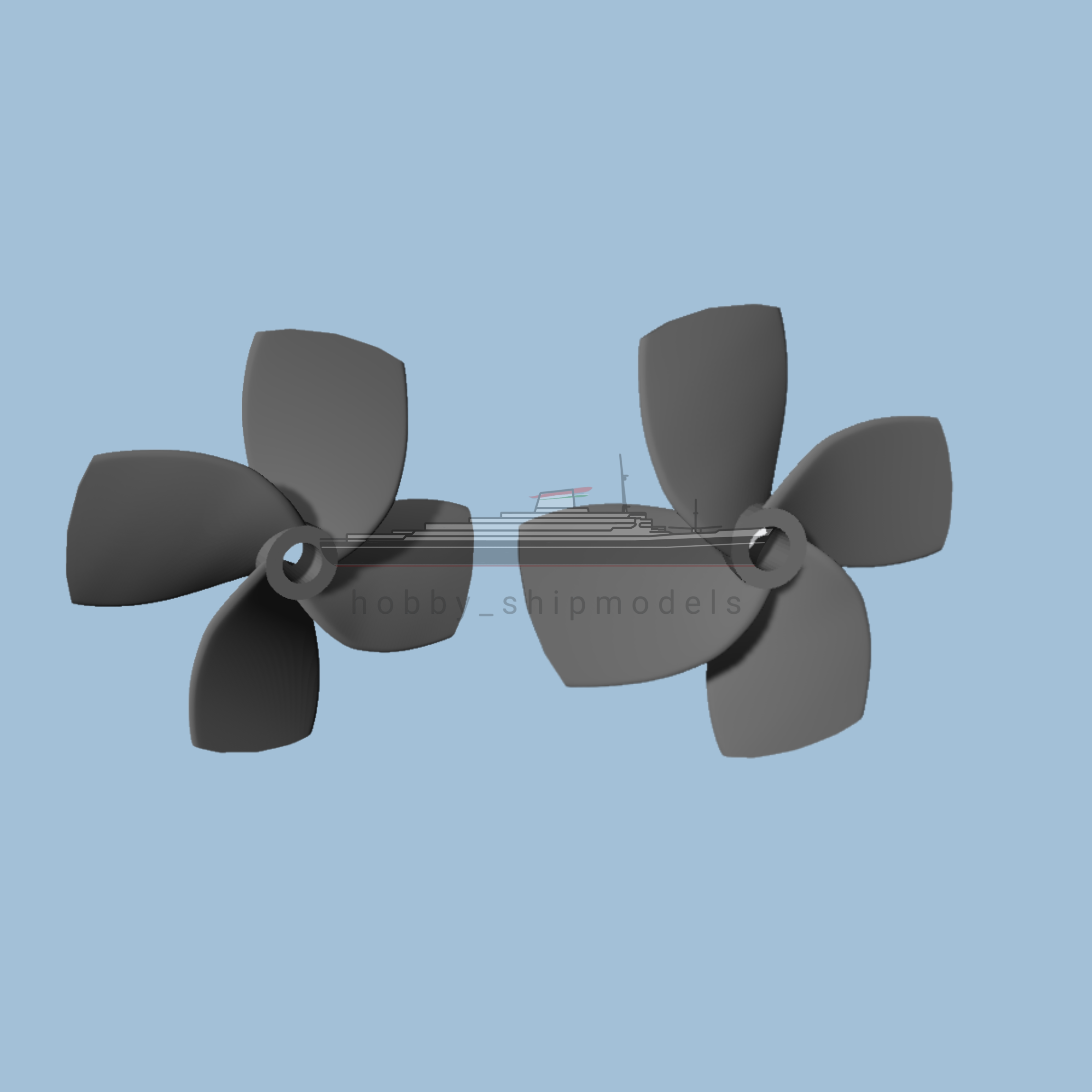

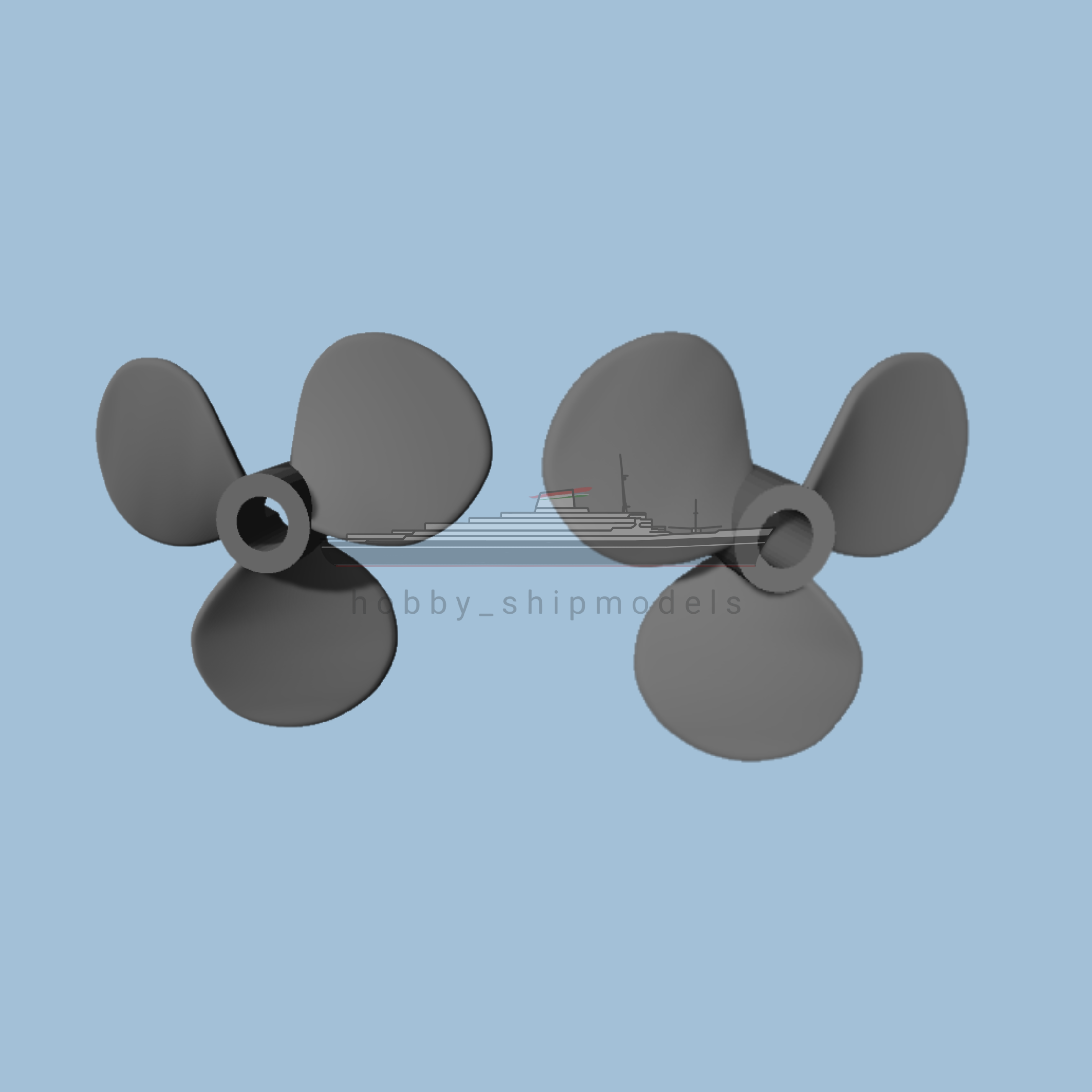

- 4-blade propeller pair (standard)

A general-purpose option typically used on smaller RC boats.

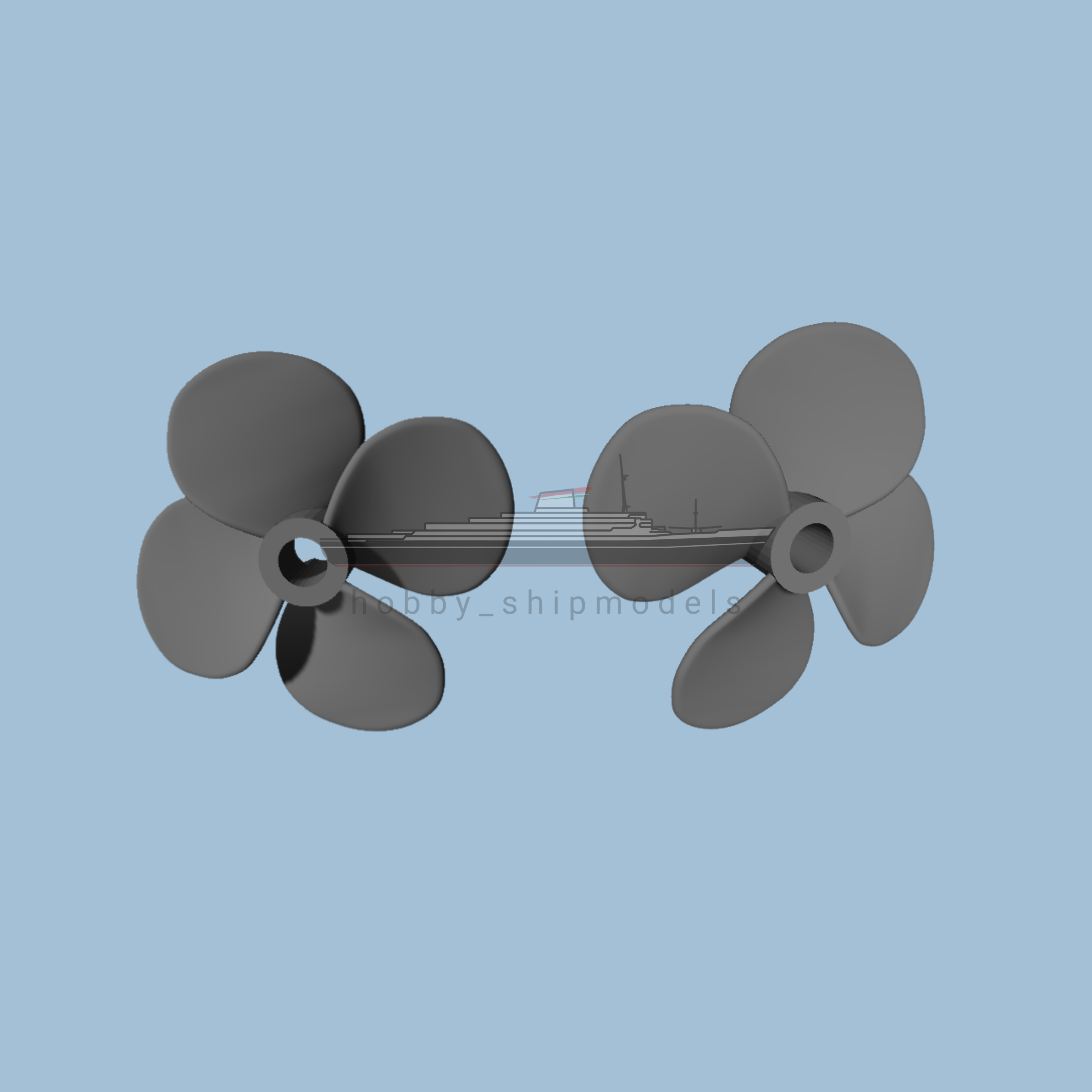

- 4-blade propeller pair (long blade)

Features extended blades, often used for heavier small-scale models.

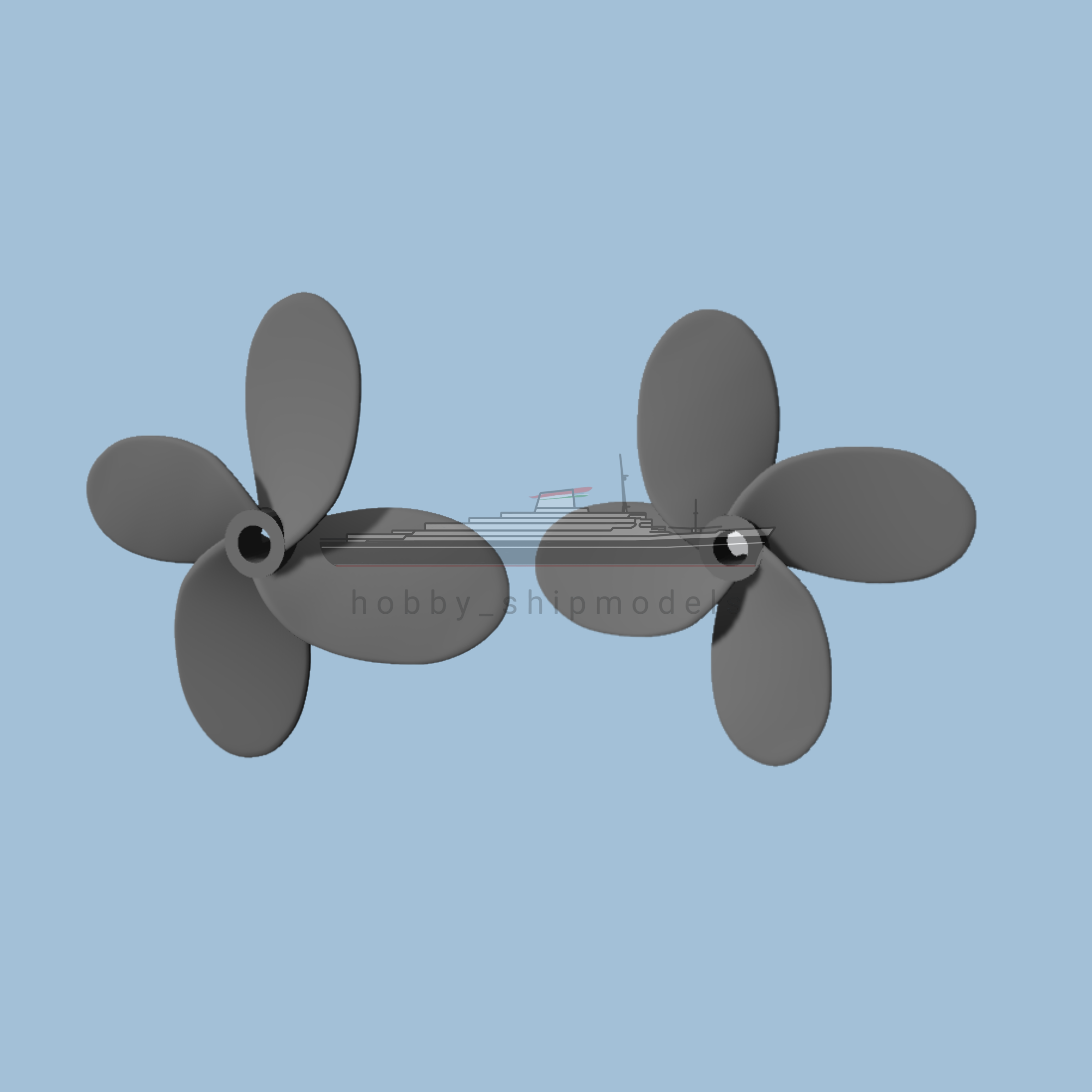

- 4-blade propeller pair (cut blade)

Designed for tugboats, workboats, and similar displacement vessels.

- 3-blade propeller pair

Commonly used for fishing boats or outboard-powered RC models.

- Surface-drive propeller pair

Intended for surface-piercing propulsion systems, typically seen in racing or fast RC boats.

🔩 Technical info:

All propellers feature a 3 mm through-hole for the shaft and a 3 mm keyway slot to fit the shaft guide. This allows the propellers to lock securely onto the shaft and rotate together with it without slipping.

Printing instructions can be found below📄

I really hope you like it! If so, please follow me, like, and post a makeover so I can see how you printed this model!

Below are some other models you might like:

3D printing settings

🖨️ Printing Guidelines:

This propeller set can be printed using either type of 3D printer:

🔵 FDM (filament) printers

For FDM printing, it is recommended to use 100% infill and a maximum layer height of 0.2 mm, although adaptive layer height is strongly suggested to better capture the curvature of the blades and reduce print time where possible. Supports are required, and tree-type supports are advised for easier removal and better surface finish. Avoid printing in PLA, as it may be too brittle for practical RC applications—prefer PETG or ABS for greater strength and durability. Once printed, carefully remove the supports, and if needed, lightly sand the blades to eliminate any remaining traces of support material.

🟣 Resin (SLA/DLP) printers

For resin printing, it's important to use high-toughness and high-strength resins. Avoid standard brittle resins, as they can easily crack or break during assembly or operation. Make sure the resin is completely cured before handling or installing the propellers. When removing the supports, proceed with care to avoid damaging the blades, and if necessary, gently sand any support marks or irregularities left on the surface.

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/0443a6e6-dd0a-4e44-acae-467e86cb1c01/Themplate-copertine-Cults-10.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/495747fd-3d93-49c8-853b-12ea8357cfd0/Themplate-copertine-Cults-26.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/b42283e9-499e-436b-a1a8-d897d784e533/Themplate-copertine-Cults-6.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/fd8b3abf-053a-4100-93be-3294b04da7e7/Themplate-copertine-Cults-33.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/18642d0a-f537-4555-b8a2-03bb0debc69b/Themplate-copertine-Cults-3.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/72e44169-654d-442b-b182-4a017379b04a/Themplate-copertine-Cults-32.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/3ded1183-2da4-46dc-b6c4-c43447eecc06/Themplate-copertine-Cults-31.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/656375ac-fb94-4671-b35b-aff2b287bac1/Themplate-copertine-Cults-2.png)

/https://fbi.cults3d.com/uploaders/29474353/illustration-file/6a50aac3-4db4-49c1-97da-f1464933fb54/27.png)