3D model description

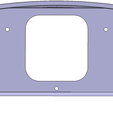

I have created a bezel for the Haltech uc-10 to be used in an R32 GT-R Skyline.

Following steps were made for the design to fit perfectly:

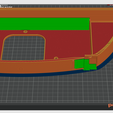

- 3D scan of the original dash cluster

- 3D scan of the dashboard itself

- several 3d print cycles to make sure that all holes align and that the display will fit and not collide with the dashboard

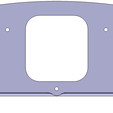

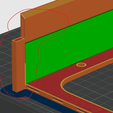

Due to the size of my printer, I had to divide the product in 2 parts and stick it together, this was done with the help of dowels (see pictures). Printing the bezel as one piece is possible if the printer You have is big enough.

For download You will find only the main part and you can divide the model and add the dowels with the slicer according to Your needs and the size of Your printer.

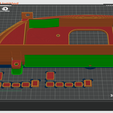

Printing was done with ASA and took around 15h with 30% infill and 0.4mm nozzle with 0.2mm layer height. In future I would even try 20% infill as i think the part is quite strong already. For printing orientation see pictures. Support was used where necessary, except the upper fastening holes.

"Glueing" was done by putting some ASA into a small can of acetone and letting it dissolve over 2 days. After that I used this solution and brushed it onto dowels and where both parts come together. After 1 day of curing, the connection is permanent and good enough for this purpose. In future projects I might try "plastic welding" (have a look on YT) to achieve an even stronger bond.

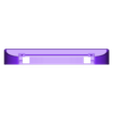

After curing, the part was sanded down with 120, then the holes of the bonding process were filled with a plastic filler and finally sanded with 400 grit paper. After that a plastic primer was used, then a base coat and finally painted in matte black (personal preference for avoiding any additional glare).

Important note:

The uc-10 display is huge and it barely fits into the R32 GT-R dashboard without the bezel (clearance to top and bottom is approx. 1mm total if centered) so the bezel itself needs to have holes on top and bottom. Display is inserted from the front with the bottom first, then put into position and then slid to the top until the bolt holes align. With this bezel NO DASHBOARD MODIFICATION IS NECESSARY and the clearance between dashboard and bezel or display and dashboard is given so that nothing is touching where it shouldn't be.

In case you need this adapter for any other display, please contact me.

3D printing settings

Printed on Qidi Plus 4

65°C chamber temp

105°C bed temperature

260°C nozzle temp

30% suport cubic infill

16 mm³/s max volumetric speed

3 wall loops with an alternate extra wall every other layer (with 2 walls the part is already very sturdy)

6 top and 6 bottom shell layers (3 for bottom and 5 for top shell is fine enough)

10mm brim was used as an extra precaution measure

Magigoo PC used for extra hold

/https://fbi.cults3d.com/uploaders/39864253/illustration-file/aae7bebb-17a8-4f48-b400-68a1a1395122/Bezel_finished_front.jpeg)

/https://fbi.cults3d.com/uploaders/39864253/illustration-file/d3f13dd3-f93a-4770-bc23-61e3f532203f/ADU7v1_Overview.png)

/https://fbi.cults3d.com/uploaders/39864253/illustration-file/553a8111-b4db-4309-b841-fe827b5f8046/ADU7v2_Overview.png)

/https://fbi.cults3d.com/uploaders/39864253/illustration-file/e225e7f3-6af8-4de2-ac4e-03a2fabc0db0/Frame_1.png)