Hi, I’m asking for your help if you can.

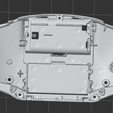

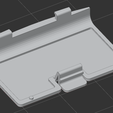

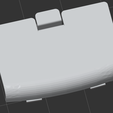

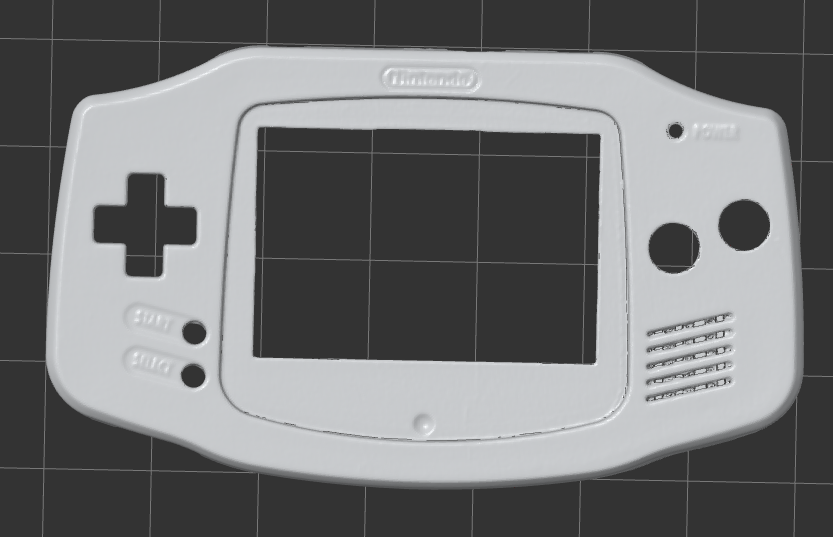

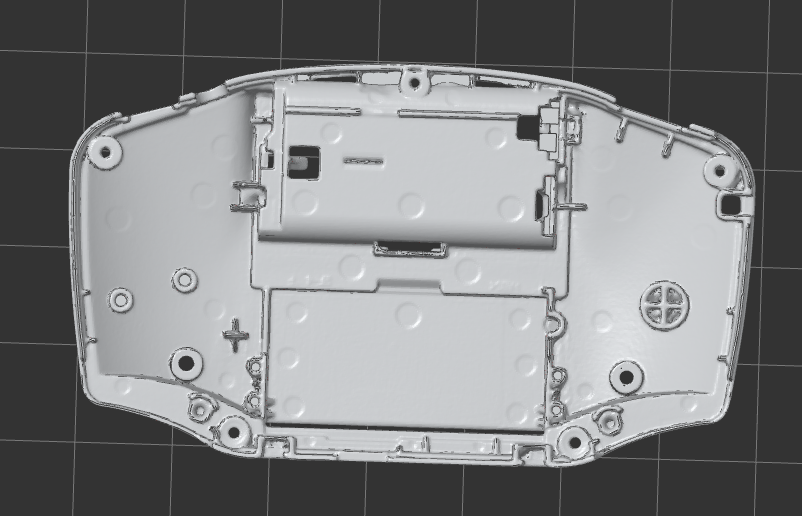

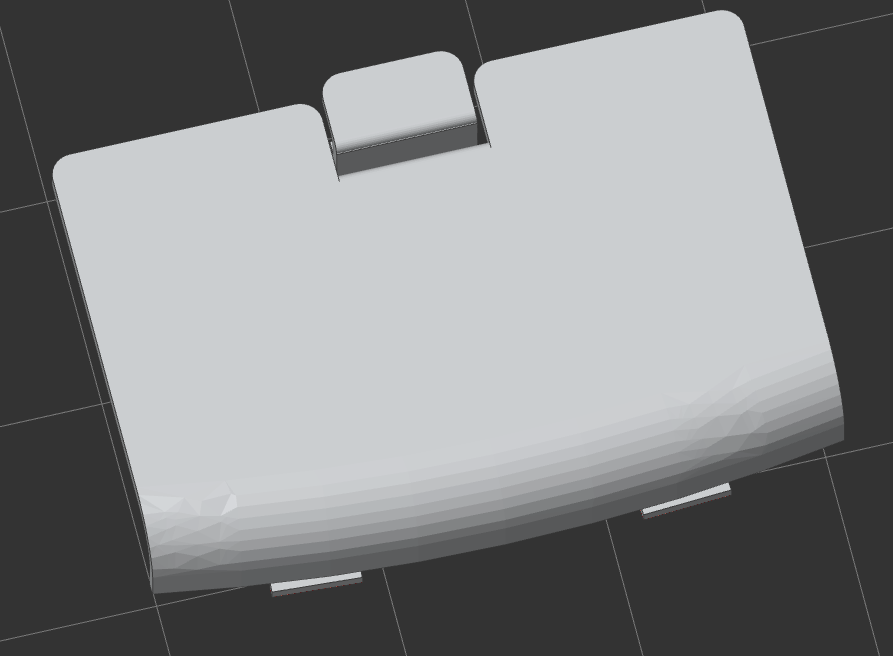

I’m testing different print settings in order to get the case as clean and uniform as possible.

I’m printing with a Bambu Lab P1P, single color.

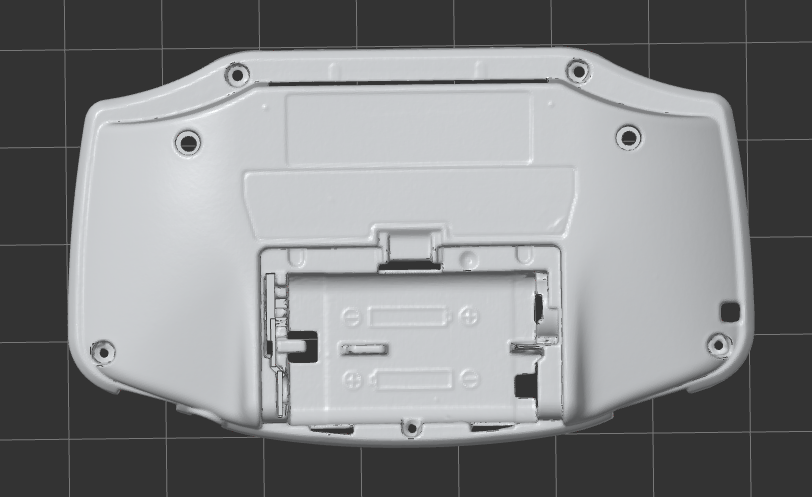

After some tests where I placed the case tilted at 60 degrees, I’m now trying to print it with the top face resting directly on the build plate. However, the Bambu Studio slicing software tells me that the face I’m placing on the plate isn’t completely flat, and it creates an unpleasant texture.

Do you have any suggestions? Thanks!

P.S. If you want, I can send you some slicing screenshots.

- 0 likes

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/605c13d5-11f7-4bef-b573-d6e7054386d9/large.jpg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/fdaa20dd-0971-49ad-9c95-f5b989be4321/8787cbfa-7190-49fd-97b1-c6a9dd4e9d29.jpeg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/8369dc5f-a504-48da-99b7-a9b7551fa2cf/aa01d0417aac6bf645c854e9aa4cd935381db48d_00.jpg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/3288e02d-a6b4-40a5-bc00-936ba534a4f0/WhatsApp-Image-2025-04-18-at-12.03.06_223030bc.jpg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/990c043c-5777-4568-85eb-53fe043210e0/WhatsApp-Image-2025-08-09-at-14.30.21_48cd44b6.jpg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/dfa8c907-9287-44ae-b649-574dca63985b/IMG_6887.jpg)

/https://fbi.cults3d.com/uploaders/30200145/illustration-file/11ec02df-2ff9-4573-9d23-f7b221af03e7/Screenshot-2025-12-04-115520.png)

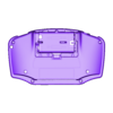

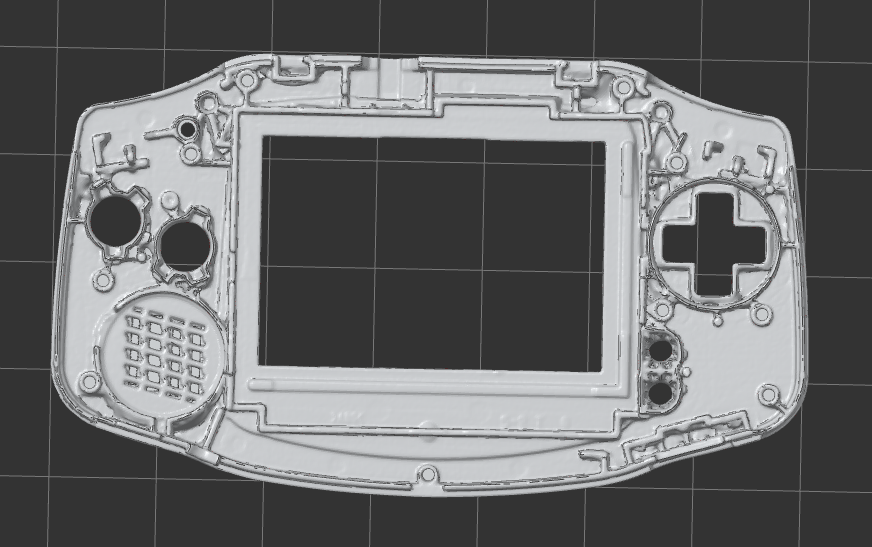

Hello! This is really great, I was wondering if you had ever taken scans of the bumpers and buttons, or if you had ever dived further into a more FDM friendly version?

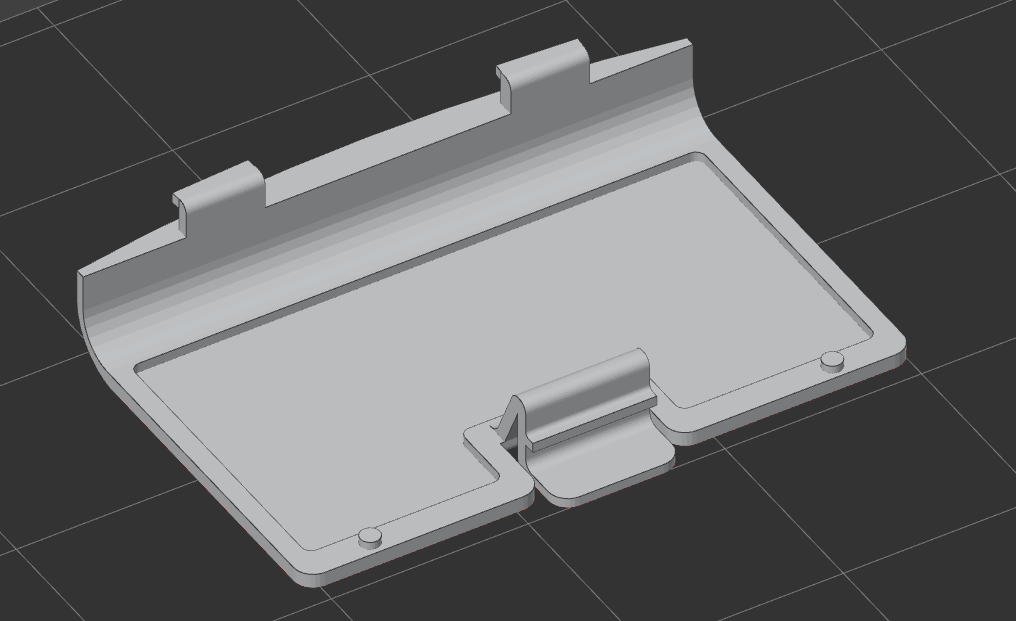

I've printed a few versions now and gotten an ok product in terms of exterior quality but I can't quite get the two shells to fit together properly because the supports create such an imperfect surface on the underside. There are also quite a few artifacts left over that make an FDM version much less friendly, most notably for me was the power switch slot is about 2/3 filled and needs to be dug out. Otherwise this has been a super cool project! The screen fit perfectly and my board and most things swapped over similarly to an OEM shell!!

Hello! Actually I have wanted to do this for a while now, I just haven't had the time to update it due to current orders I have. These changes will most likely be made by early next year.

I will add the buttons and bumpers early next year as well, though I need to tinker a little to make the bumpers fdm friendly.

I will remove the artifacts using a new software I'm learning, the one I was using previously is no longer available and I changed my computer.

In regards to FDM printng, I will play a little more with that as soon as I finish with my current projects.

Thanks a lot for the feedback! I'll try to work on these changes when I have a breather at my job.