Important settings summarized

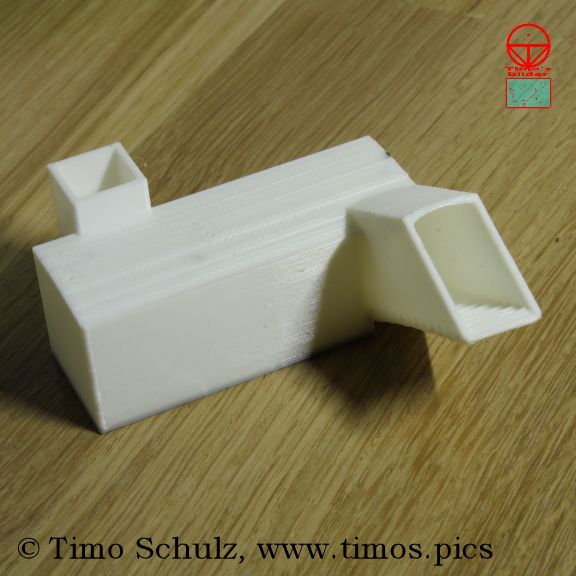

Support structure

- Normal support structure

- For the support structure, the setting Burst print bed should be activated

Positioning

- Normal position with the underside on the print bed

Print bed adhesion

- Brim is recommended as the corners often peel off with a poorly leveled print bed

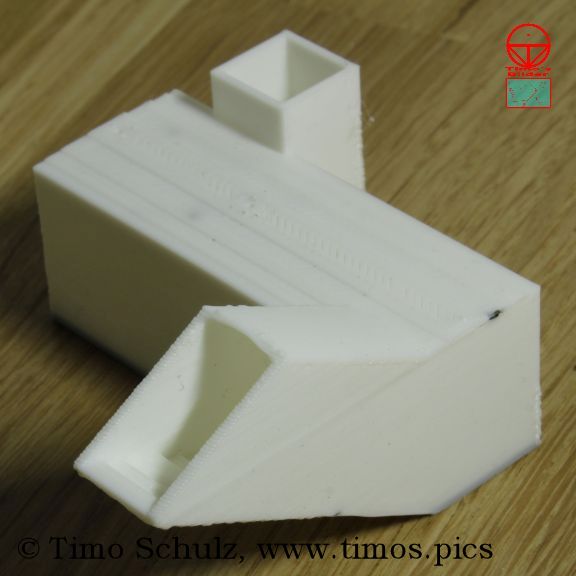

Building printing

NOTE! This wire model is not suitable for real building pressure and must be adapted by a specialist!

Do you want to have this model printed as a real building? Get advice from such a building printing company. And have an appropriate specialist prepare the wire model so that it can be printed as a building.

Positioning and scaling

Minimum scale: M: 1:100, recommended scale min. M: 1:50

Hardware settings details

Printer: Creality CR 10S Pro V2

Filament: Renkforce PLA

Recommended print bed: Spring steel on magnet

Nozzle: 0.4mm

Software settings details

Quality:

Layer thickness: 0.2mm

Line width: 0.4mm

Line width of the first layer: 100%

Walls

Number of wall lines: 4

Hook on: Optimize wall pressure sequence

Fill gaps between walls: Everywhere

Top/bottom

Top/bottom thickness: 0.8mm

Upper layers: 4

Lower layers: 4

First lower layers: 4

Lower/upper pattern: Lines

Lower pattern for first layer: Lines

Filling

Filling density: 20%

Line spacing filling: 6mm

Filling pattern: Cube

Filling layer thickness: 0.2mm

Material

Printing temperature: 195°C

Pressure plate temperature: 50°C

Flow: 89.89%

Speed

Print speed: 50mm/s

Filling speed: 50mm/s

Wall speed: 25mm/s

Upper/lower layer speed: 25mm/s

Movement speed: 150mm/s

Speed of the first layer: 20mm/s

Skirt/brim speed: 20mmn/s

Number of slow layers: 2

Movements

Tick on: Activate feed

Feed distance: 6mm

Feed speed: 45mm/s

Minimum movement for feed: 1.5mm

Hook on: Z-jump during feed

Z-jump height: 0.2mm

Cooling

Tick on: Activate cooling for printing

Fan speed: 100%

Limit value for normal...fan speed: 10

Initial fan speed: 0%

Normal speed of the fan at height: 0.6mm

Minimum time for shift 10s

Minimum speed: 10mm/s

Support structure

Hook on: Generate support structure

Support structure: normal

Placement of the support structure: touch print bed

Angle for overhanging support structure: 45.0°

Pattern of the support structure: zigzag

Number of wall lines of the support structure: 1

Density of the support structure: 10%

Tick on: Activate support structure interface

Hook on: Activate supporting roof

Hook on: Activate supporting floor

Density of the roof structure: 40%

Line spacing of the roof structure: 2mm

Density of the floor structure: 33.333%

Line spacing of the floor structure: 2.4mm

Pressure plate adhesion

Printing plate adhesion type: Brim

Width of the brim element: 8mm

Instructions for loosening the support structure

if you have a dual extruder, use water-soluble support structure. This is because loosening conventional support structure is tricky.

/https://fbi.cults3d.com/uploaders/30003955/illustration-file/356c2036-74f0-4c75-acc6-d17aa3ea3853/image016-4.jpg)

/https://fbi.cults3d.com/uploaders/30003955/illustration-file/da8a6823-28d4-4fb7-bfa8-9f524732ded8/image021.jpg)

/https://fbi.cults3d.com/uploaders/30003955/illustration-file/be934bb2-6262-4305-94c0-6ec08be2ad4d/image003.jpg)

/https://fbi.cults3d.com/uploaders/30003955/illustration-file/d318a420-2a9c-4d79-b553-0a7a9ca8d716/image075-2.jpg)