News in V1.3 :

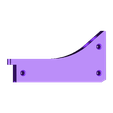

bow bracket enhancement

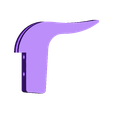

front handle enhancement

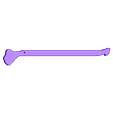

short arrow adapter

News in V1.2 :

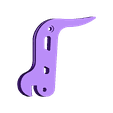

Aluminium trigger is now better for the string

The sight is now operational

News in V1.1 :

STEP files to have the trigger done in aluminium + trigger improvement + documentation improvement

This is a hybrid Wood/3D printed sliding repeating bow. Here is the video of the first shooting test I made:

https://youtu.be/lyPXGM5R--o

here is te latest test I did:

https://youtu.be/jqxMp1IbqTU

Nearly all the ideas in this system come from Jörg Sprave's Instant Legolas, I just made a 3D printed version, and so most the credits should be his. Here is one of his video about his system:

https://www.youtube.com/watch?v=f3fcNyZoEIw.

The build manual is available here:

https://drive.google.com/open?id=1RD5iw1qI5nfNlczbd70f5E7fhNj2LtFV

The goal was to have the easiest woodwork as possible. Neverteless the arrow rail is still a difficult work to achieve. So I asked a professional wood worker to get a really straight rail.

I use it with a Mission Hammr compound bow.

I printed all the parts in with ASA filament since it is pretty similar to ABS and can endure a lot of stress. The trigger is the critical part since the draw weight can be really high on a compound bow and I would advise to have the Triggered done in aluminium. Nevertheless, the 3D printed ASA filament trigger worked fine for 20 pounds draw weight, but I would not count on it on the long run. An assembly manual is provided, and the system can be used for both lefty and righty.

This represents several 10th of hours work, and improvement are to come soon, depending on the feedback I get. That is why I do not give it for free but for a really cheap price.

Parts list:

Bracket on the bow

Bracket.STL

Bracket_1_x2.STL

Front Block:

CentralFlanc.STL

CentralFlank1.STL

FrontStop.STL

Lift.STL

FrontHandle.STL

Rear Block (Handle):

Be careful of the Flanks which should be printed twice, and one is mirrored. Bracket attached to the bow:

Wood parts:

1x rail 800x42x10mm

2x sides 670x65x10mm

Screws & bolts & springs:

The 3D printed parts are designed to work with M3 screws which are really common all around.

The world except for those using imperial units. But I am sure there is a x/64th inch screw which would fit really nicely.

11x M3 wood insert bolt

8x M3 Metal insert bolt

8x M3 nuts for the left & right handle

22x M3 x 14-16mm screws

1x M3 x 25mm screws with no thread at the base for the trigger

1x M3 x 30mm screws with no thread at the base for the lever

3x M3 x 40mm screws

2 or 4x 5mm diameter compression spring for the trigger an the lever

Some washers to even the screws heads pressure on the woods.

Improvements are coming, like a dedicated sigh and a better front handle.

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/83d2f748-4df5-47ba-915b-64ea46c82e8d/SlidingrepeatingBowManual.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/c6fc8757-9d4a-4435-93a4-ecbcfe3dc19e/Overhall.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/8e30a28e-0c69-4dde-877f-749d3df3a5d9/DSC_1821.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/3bdfd0df-9fb5-4e99-aac6-3ec02f7043cd/c4b1ccb0-662f-4d65-adce-bb355a9ff308.png)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/5b36206b-4d3c-4af6-8584-30af201a26aa/DSC_1769.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/511e1057-321f-412e-bb2c-600ce7e4685e/SlidingLegoliniIronSight_V2_Clearance.png)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/6905a823-c59a-4148-98a1-6de7af0239ec/03.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/5177fbd1-b579-43b3-ad1f-99bb5efe1f03/FingerSaverX2_3.2mm.jpg)

/https://fbi.cults3d.com/uploaders/14930587/illustration-file/45f1d68c-96a5-49e2-a18f-6373b8bd7c6d/DSC_1786.jpg)