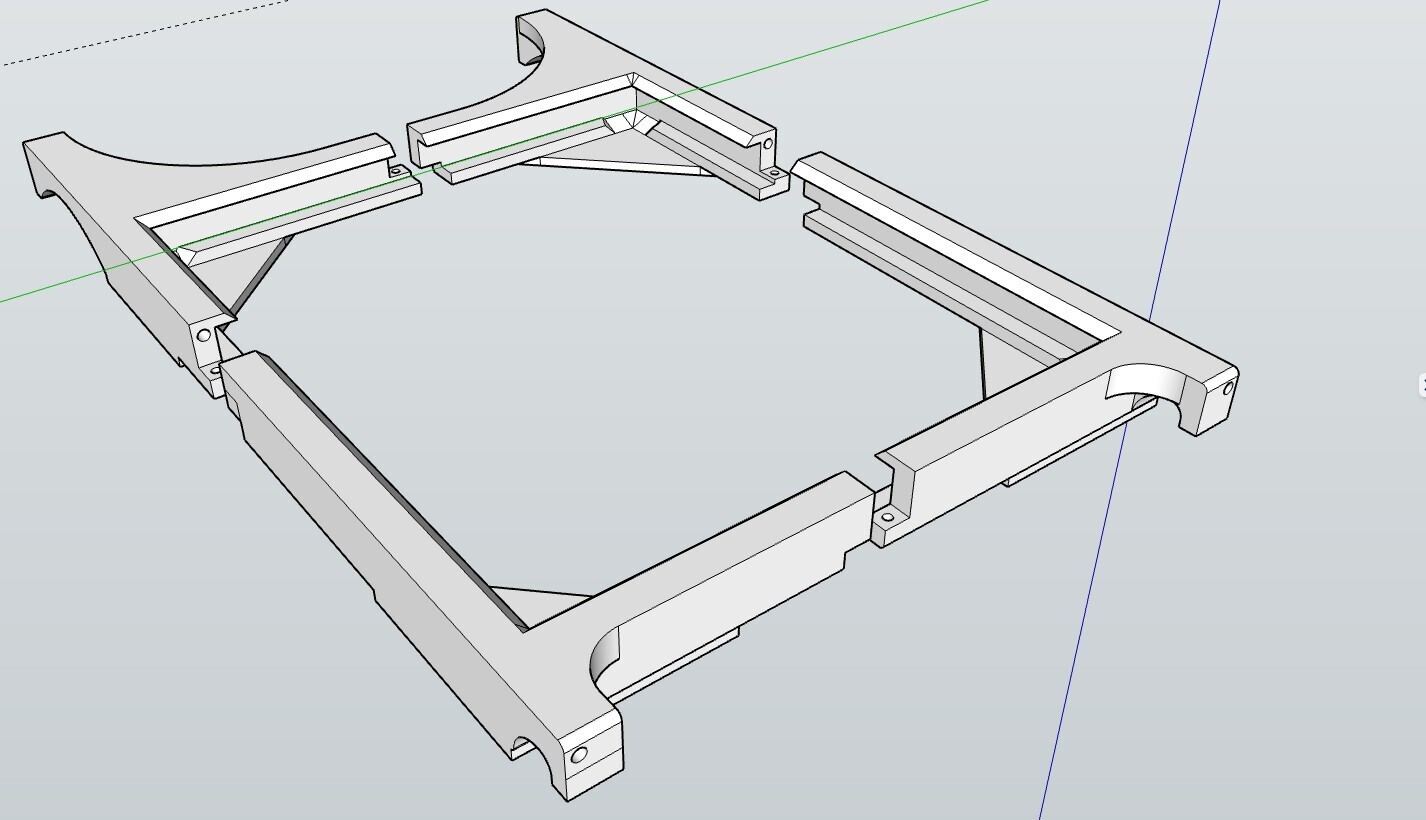

Beschreibung des 3D-Modells

*** RECENTLY UPDATED*** Changed the orientation of the SLD file so it does not require rotating before printing and chamfered a sharp corner on all 4 parts.

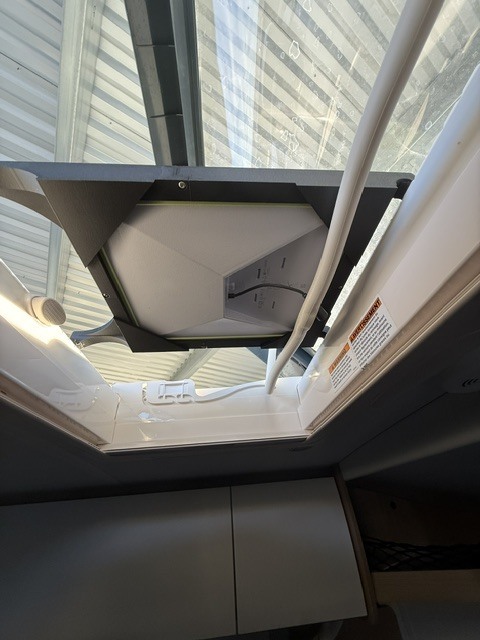

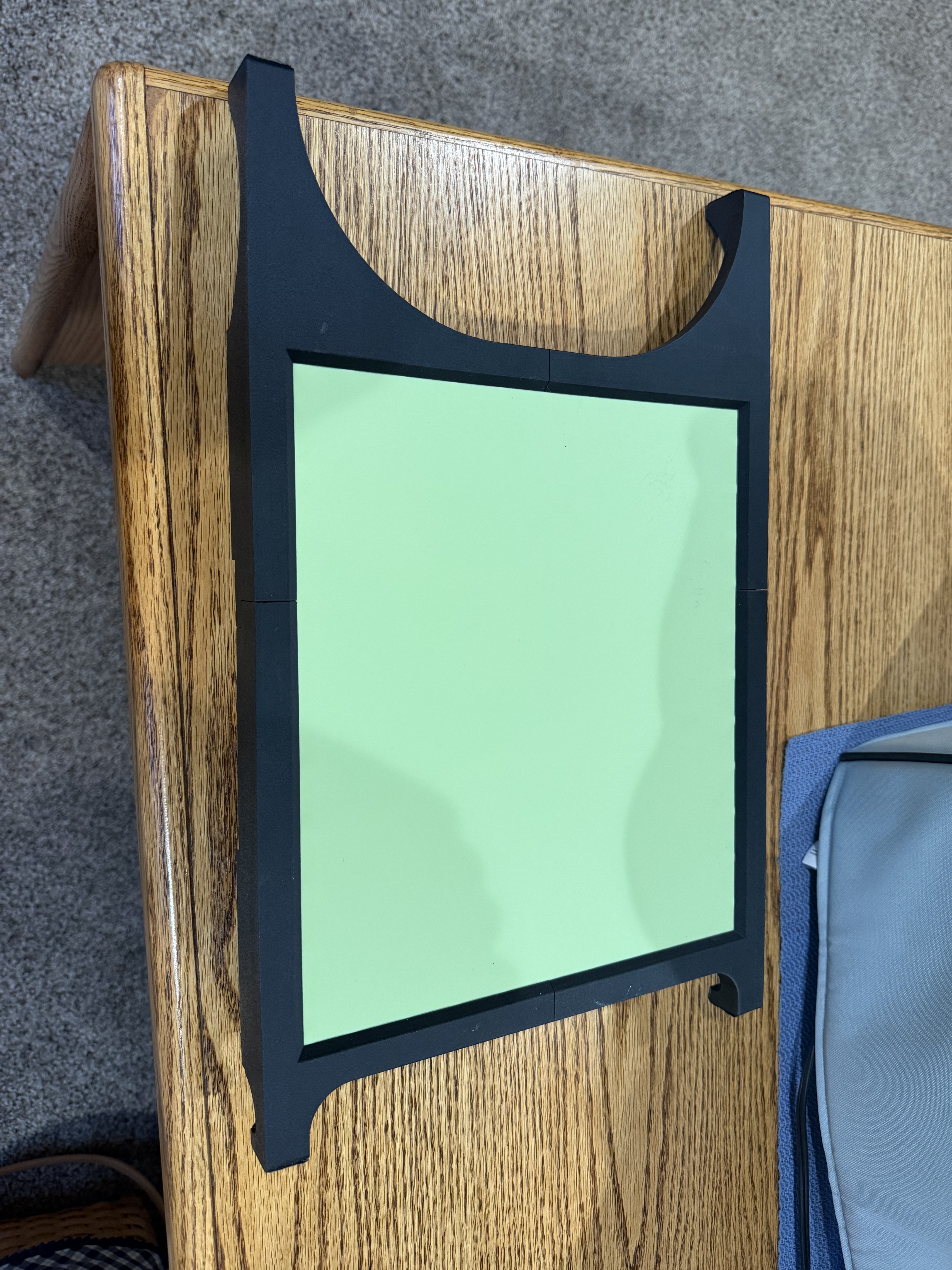

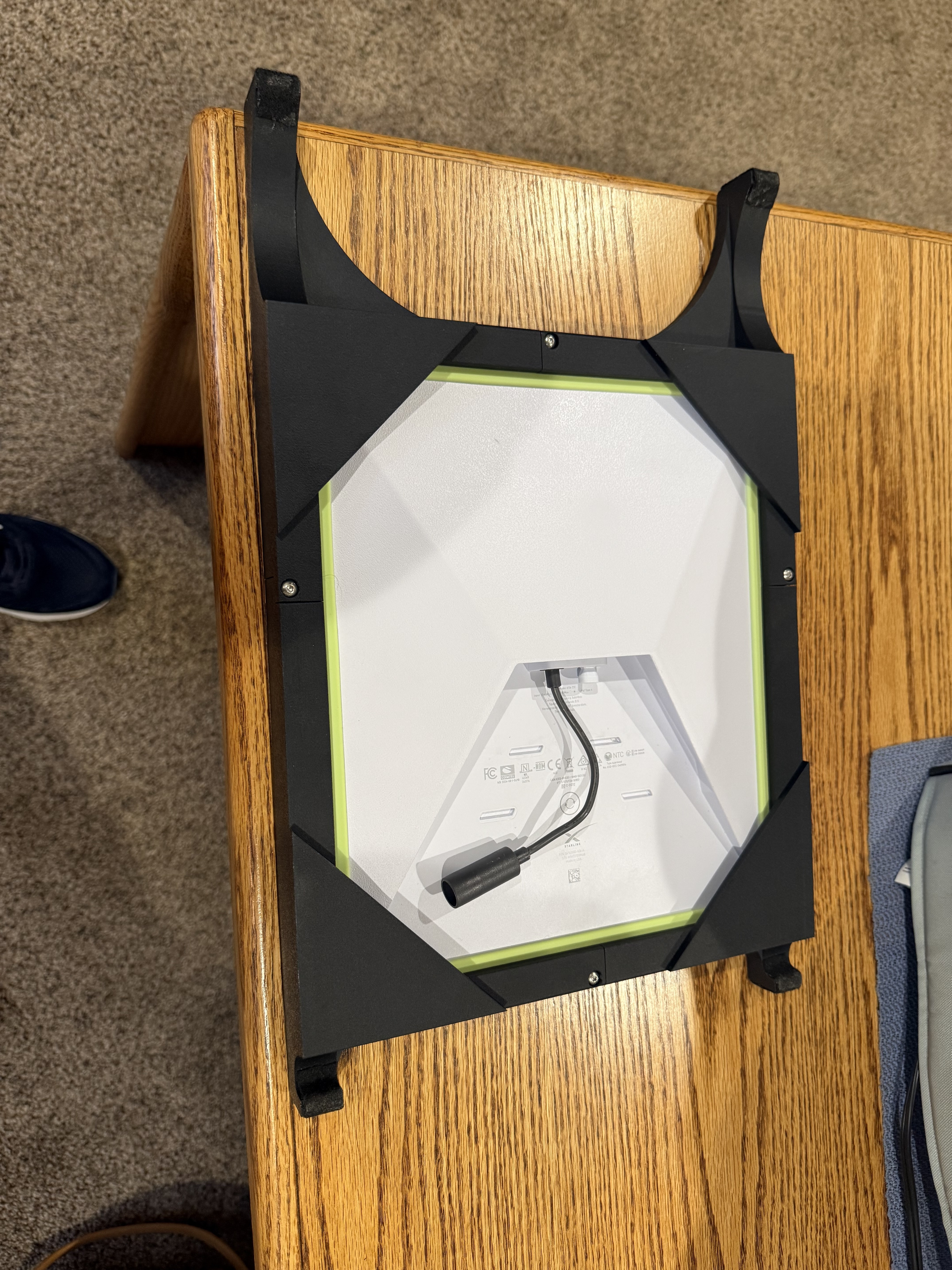

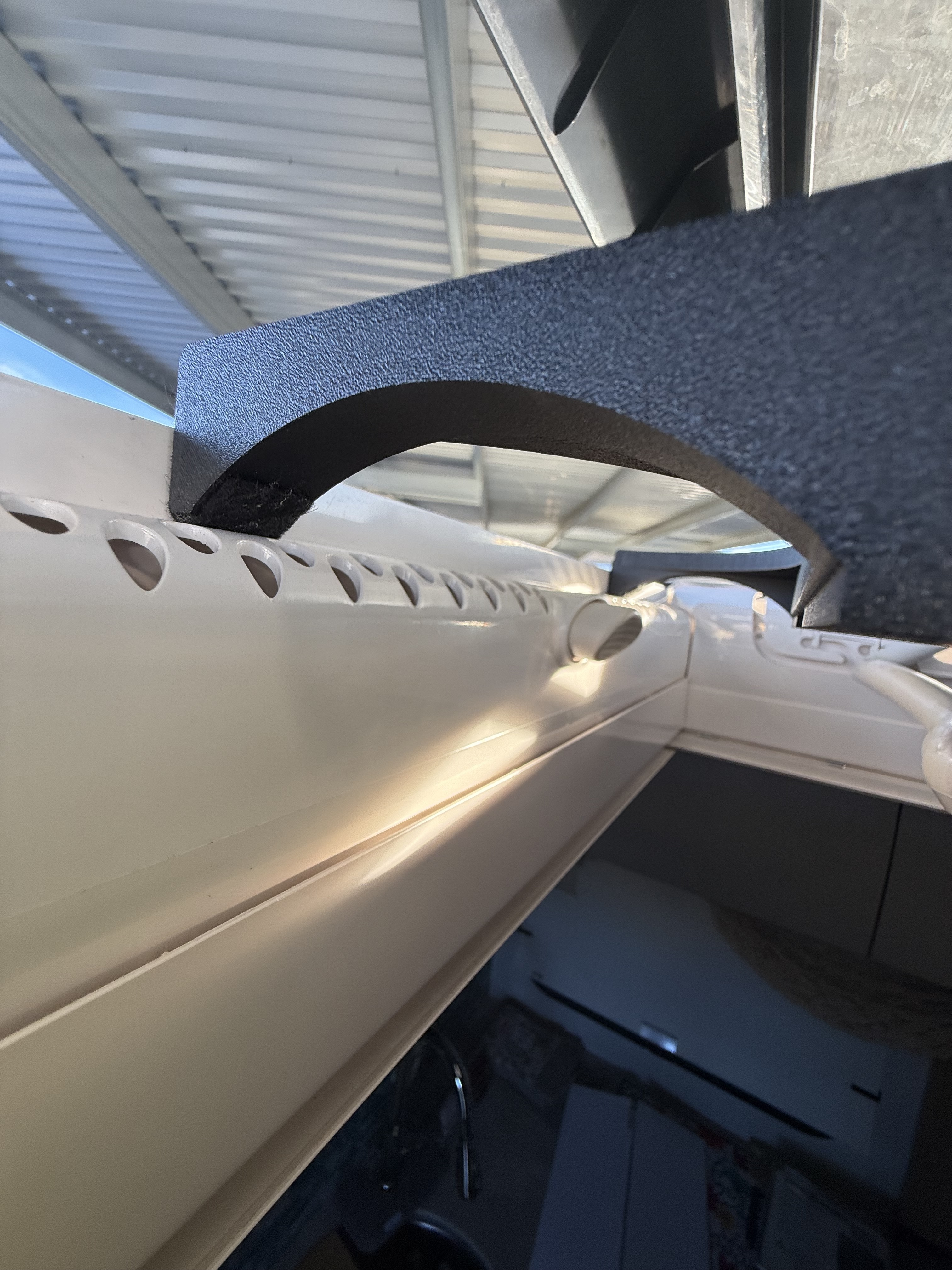

Here's a Starlink mini mount that fits in the Dometic Skylight that is commonly used in Leisure Travel Van LTV RV's. It took a few iterations to fine tune it so that there's enough clearance (barely) to put in the white posterboard (thermal barrier) above the Starlink while still clearing the handle for the skylight itself. The Starlink mount is very shallow so the skylight screens can be opened/closed and there's room for any other reflective insulators you might use underneath (watch out for excess heat).

*** IMPORTANT *** This mount is designed to be used on a Starlink with a silicone cover only. If you try to fit this without that it will be too big. That provides some abrasion resistance and allows for some part to part tolerance. https://www.amazon.com/dp/B0DQ4LMLBC?ref_=ppx_hzsearch_conn_dt_b_fed_asin_title_2&th=1&fbclid=IwY2xjawOLTuNleHRuA2FlbQIxMABicmlkETFkMmt6Vm5aS3BZMDZobG5Oc3J0YwZhcHBfaWQQMjIyMDM5MTc4ODIwMDg5MgABHt_SwGiyhYAWVwYKIO_VdfAiRoccHh9CjGdrkIbsFskqGKKWRrXfvhGVPI4D_aem_HJ47ypS0ImTyqx05ODZElQ

I printed this using high temperature, UV resistant ASA-CF and added felt pads to the contact areas to avoid damaging the skylight. You can still use the Starlink pole mount with the appropriate tripod mount to use this outside the RV when blocked by trees.

Its a 15 hour print on my machine and it burns just under 500 grams of filament (1/2 a roll).

3D-Druckeinstellungen

Recommended Material: ASA-CF

0.4mm nozzle with 0.2mm layers

5 layers for top, bottom and walls.

40% infill using gyroid pattern

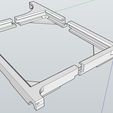

ORIENTATION and SUPPORTS: No supports are needed. If your slicer says they are, then the part is oriented incorrectly. There is a time lapse video of the part being printed as well as the Cults3D autogenerated rendering at the end of the picture list above that shows how it should be oriented. I have reports that some users had the part come into their slicer sideways and tried to generate a lot of supports. If this happens, just change the face on the plate.

ASA-CF does not usually require an enclosed and actively heated chamber but I had one so used it to print at 55C with glue compatible with ABS/ASA. PA glue is not recommended with ASA-CF as it may not release when cooled (ask me how I know). I've tried printing in ABS with a brim without success but have not yet tried a raft. If that works I'll update this posting. Please drop a note if on what you tried that worked/did not work. This shape is not very friendly for high shrinkage material printing so -CF and -GF will have a significant advantage. Also note, the use case for this is HOT and in direct sunlight. Using fiber filled materials are usually better for long term creepage. I will try a PPA-CF but that's expensive and much stronger than needed for this application.

Holes are sized for 4mm heat set inserts

Recommended screw: M4x12 mm

*** OPTIONAL FOR ADDED STRENGTH *** The design includes a 5mm hole that goes through the entire part on both sides and terminates above the foot that supports the Starlink. This is sized for a 5mm carbon fiber rod (available from Amazon) that can be installed to strengthen the design should the plastic fail. This is not needed for the printing material and guidelines mentioned above but if you try to use a material more subject to creep or choose to use a lighter infill % and wall thickness to speed up the print and save money, then this should be considered. https://www.amazon.com/dp/B0BX94YQWP?ref_=ppx_hzsearch_conn_dt_b_fed_asin_title_1&th=1

/https://fbi.cults3d.com/uploaders/35846290/illustration-file/4ac5e937-8aa0-423c-81c8-1268dea1a584/IMG_6757.jpeg)

/https://fbi.cults3d.com/uploaders/27680315/illustration-file/e75384c5-e897-424d-9dec-b63cf9d3e99f/shape_0138.jpg)