All rotating equipment generates "Anti-Torque" as a reaction to rotational torque.

When used on the ground, "Anti-Torque" is absorbed by the ground and is not often noticed.

However, it is a significant issue for aircraft used in the air.

This phenomenon is widely known, but experimental devices that allow for hands-on experience are rare.

Therefore, I attempted to create an experimental device with an aircraft-like shape and operation that would reproduce this phenomenon and allow users to experience countermeasures.

Aircraft movement is expressed by pitching, yawing, and rolling axes that pass through the center of gravity.

The previously constructed "Gyro Effect Tester" was configured specifically for the pitching and yawing axes.

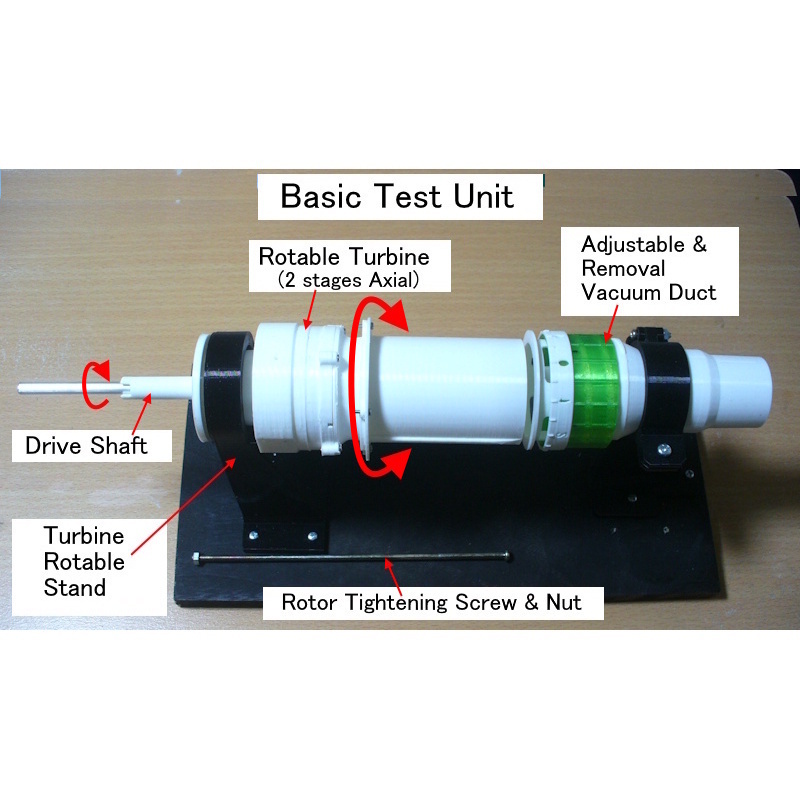

This time, I constructed an experimental device (with a bladed rotor) specifically for the rolling axis.

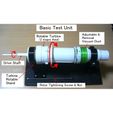

A. Features of this Device

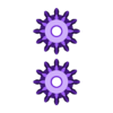

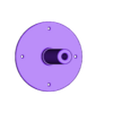

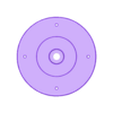

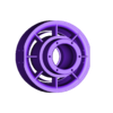

① Turbine: Two-stage axial-flow Turbine: Vacuum cleaner-driven, variable speed

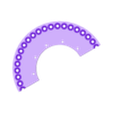

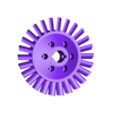

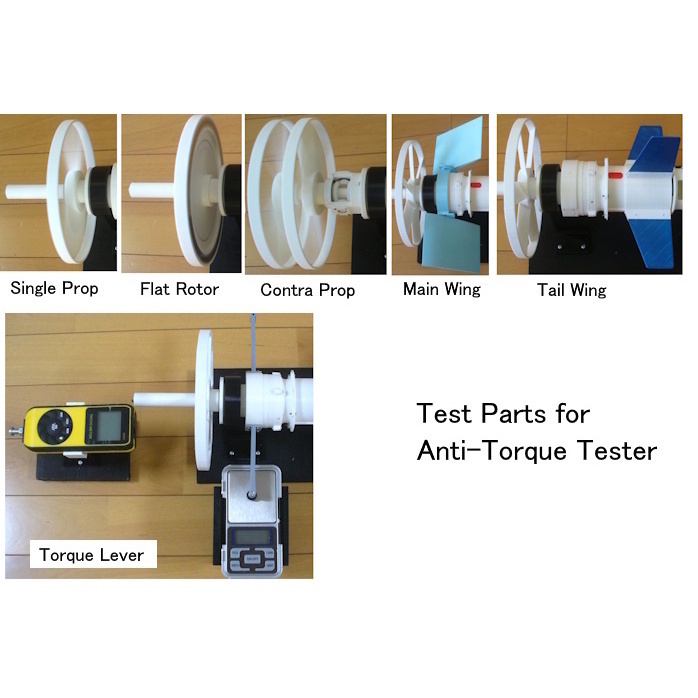

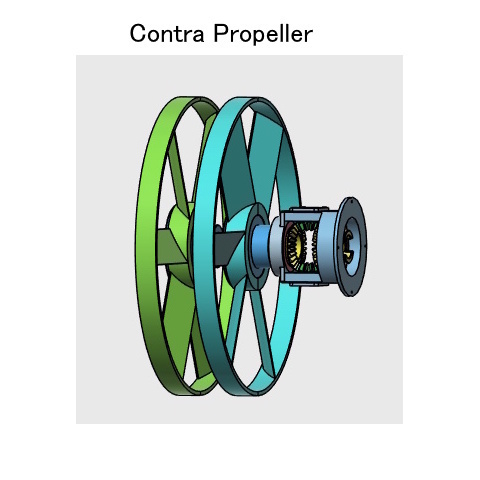

② Rotor: Single Propeller, Contra (Counter-Rotating) Propeller, bladeless Rotor (high inertia)

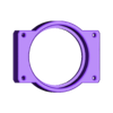

For safety, a ring is attached to the outer periphery of the propeller.

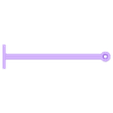

③ levers for measuring anti-torque is provided.

④ Wings for anti-torque cancellation are provided.

⑤ Experiment Details: The video was recorded at approximately 1,000 RPM.

- Free-Running

Accelerating and decelerating the Propeller, observing how the rotation of the main body changes due to anti-torque.

- Anti-torque measurement

Attaching lever with a known radius and measuring the force with a scale.

- Experimenting anti-torque cancellation by Wings

Trying to see if the anti-torque can be absorbed by the propeller wake.

- Experimenting the effectiveness of Contra Propeller.

Replacing the propellers with Contra Propellers and observing the generation of Anti-torque.

[Video] https://youtu.be/maLaSsZL2ys

I learned a lot by making this model.

- Anti-torque measures for the engine (including propeller) alone include "Contra Propellers" and "Reverse-rotating Engines," but both have problems in terms of initial cost, operation, and maintenance, so they are not widely adopted and instead rely on measures to be taken on the aircraft itself.

-Aircraft-side measures include the following:

Adjusting the left and right wing area, the difference in the angle of the wing tabs, shifting the engine mounting angle, and wing operation (pilot skill)

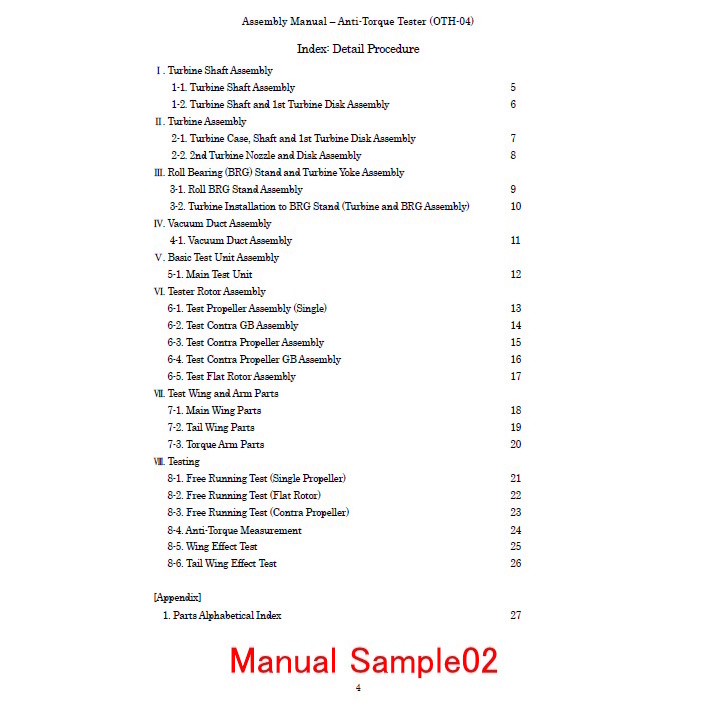

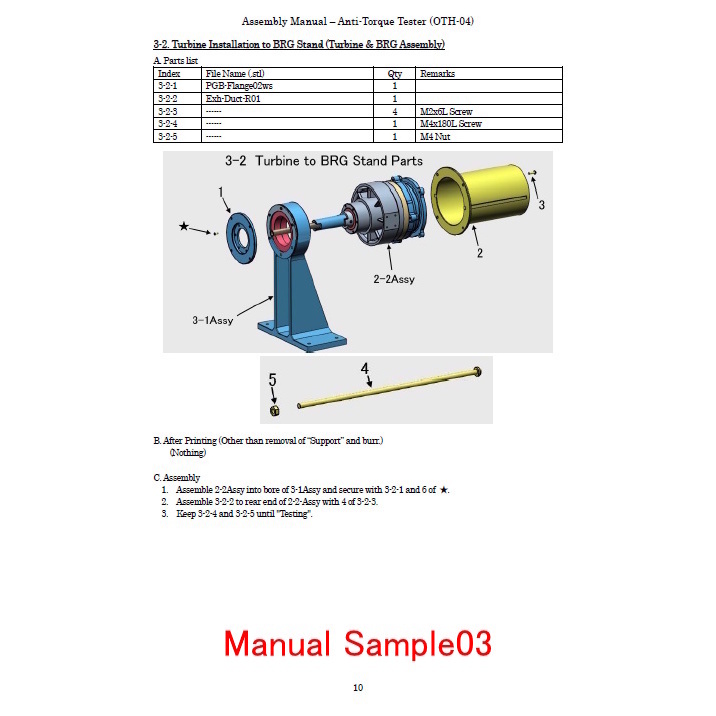

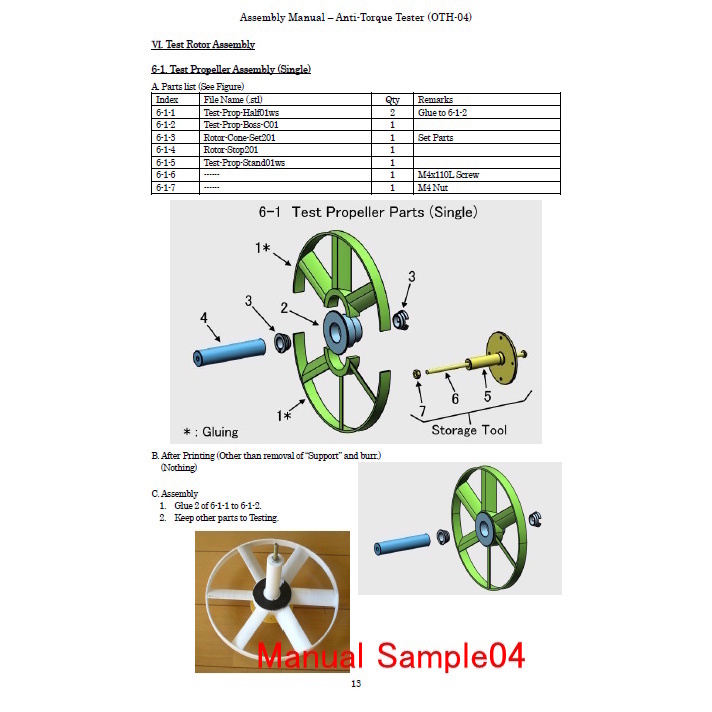

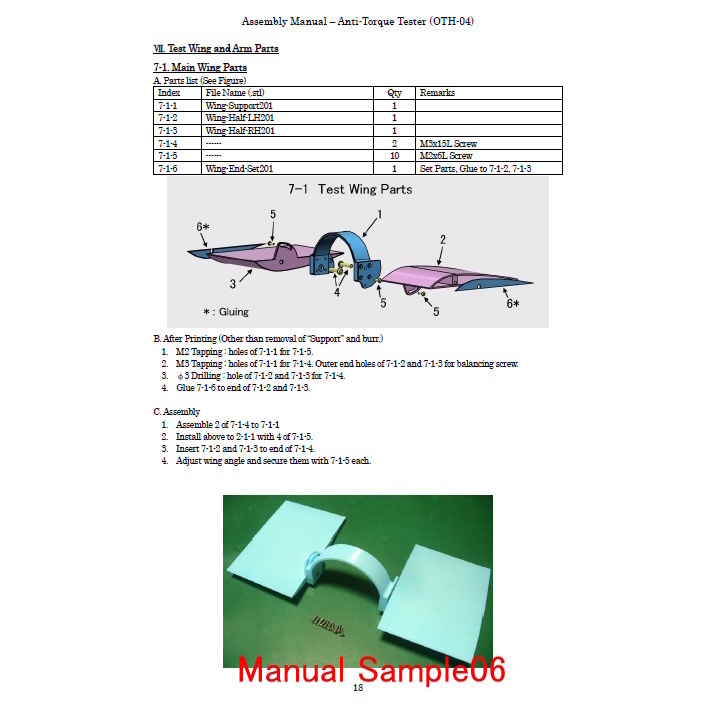

B. Assembly Manual (PDF format, total 28 pages)

The detail assembly manual including "Parts-List", "After printing treatment" and "Assembly procedure" are prepared based on "Standard Skill (Filing, Drilling, Tapping and painting)".

In order to make it rotate and move smoothly, careful adjusting center line and finishing moving surfaces are needed.

C. Purchase Parts Information;

- Bearings- 6800 (10x19x5, Open Type) (x1), 6801ZZ (12x21x5) (x2), 6803 (17x26x5) (x2),

6806ZZ (30x42x7) (x2), BR6/12ZZ (6x12x4) (x2)

- Aluminum Pipes- φ6x1tx162L

- Screws

Micro screws M1.4x3.5L & M1.4x6L - Direct screw-in to 1 mm dia hole (No nut)

The M1.4 Tap, it will be necessary for AL Pipe.

Screws & Nut- M2 x *, M3 x * -, M4 x *, M5 x *- See Parts List

?

D. STL file

Total STL files are 49 items including the stand and tools.

“ws” of last 2 digits of file name means “With Support” special designed.

E. Total Net Print Time: Approx. 107HR

- (Estimated as case of PLA, 0.4mm Nozzle, 0.2mm Layer Height, 40% infill and No raft and support)

Note: When at actual print, each parameter may be adjusted by your experience.

F. Printing settings

Raft, Support, Layer Height, Infill: Depending on your experience.

My models were printed by "idbox" using with 0.4 nozzle, 1.75 PLA.

Rotating parts such as Turbine Rotor parts are recommended 100% infill.

[Reference] My Cotra (Counter Rotation) Propeller Related Models

https://cults3d.com/en/3d-model/tool/propfan-engine-future-study-model

https://cults3d.com/en/3d-model/tool/propfan-aerodynamic-turbine-type-pitch-changeable

https://cults3d.com/en/3d-model/tool/propfan-planetary-gear-type-pitch-changeable-full-exhaust-duct-version

https://cults3d.com/en/3d-model/tool/jet-engine-component-counter-rotating-propeller-pitch-changeable

https://cults3d.com/en/3d-model/tool/wright-flyer-1903-power-plant

I do hope your success!!

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/0483ee2f-4783-44e6-a534-7f08edb1148a/01-Basic-Test-Unit101.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/d5dba3a8-f1c1-4e84-b69f-78e24a3149c2/Engine-000.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/30bc66e0-fcc7-4c0b-92d5-c78c638ccc63/P0-Engine-Assy.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/4ad1790b-a3ee-4e58-bb30-5c759f5c1a06/P0-Engine-Assy01.JPG)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/42e2b085-0a45-44bc-af95-fbe9c5b44518/00-MRH-Head-Stand-Assy01.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/689dafbf-c022-4d99-92f6-de60ca8b521d/05-Final-Assy01.jpg)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/b26fb69d-61e6-45a5-92c3-156b1048f2b7/VN-Link-Assy01.gif)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/c5962b96-554a-4f45-ba5e-e7bbd5a3732e/00-3BSN-Phase1.gif)

/https://fbi.cults3d.com/uploaders/13344378/illustration-file/7309d894-346d-4374-ba2a-71c1c314554e/00-Engine-Assy04.jpg)