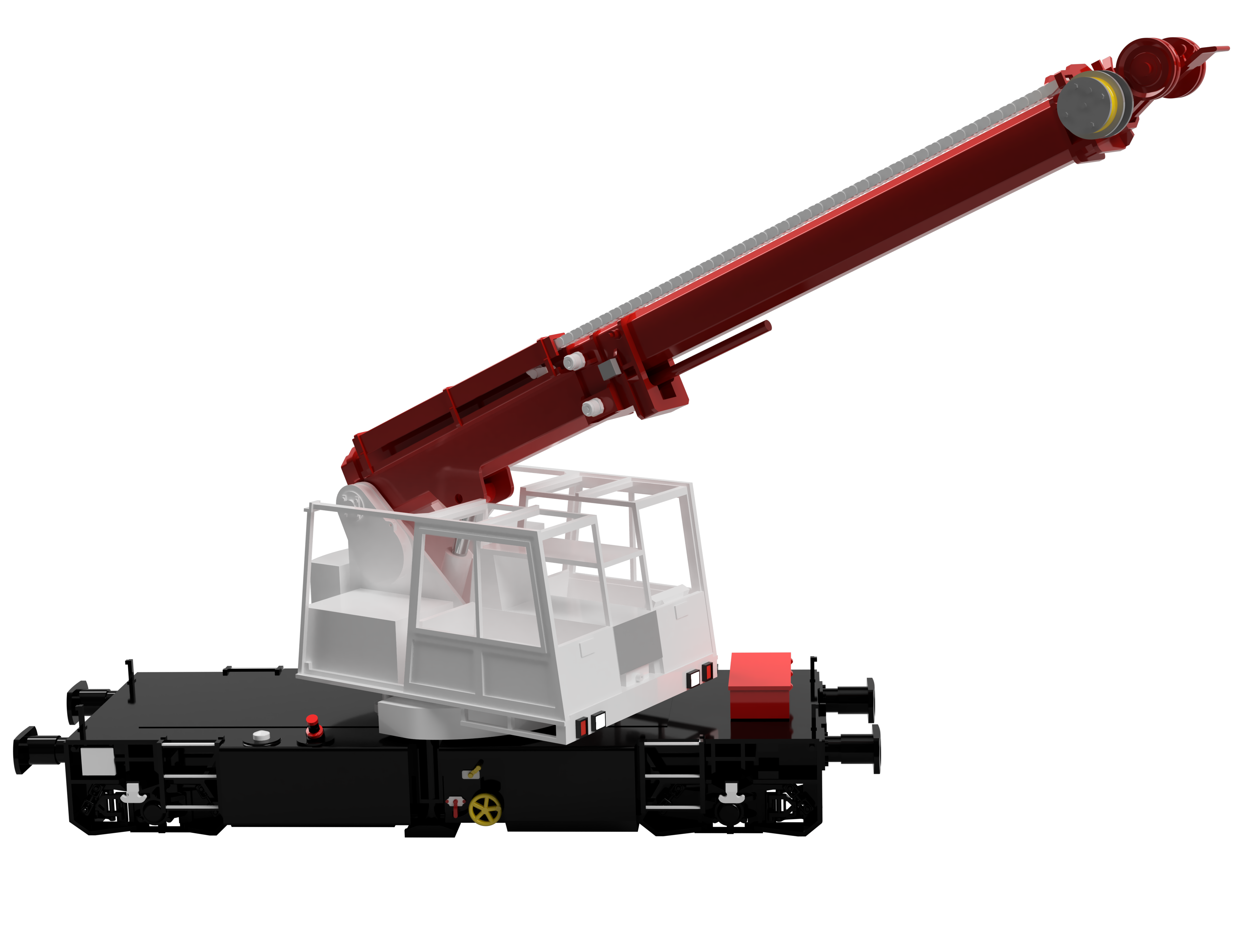

Descripción del modelo 3D

The model of the SNCB / NMBS 's Gottwald - ABT CS 10.05 railway crane (Type 9584).

The wheels and couplers are not included and you will have to buy them of the shelf.

The wheels used should classic 10.5mm in diameter on the riding surface (and at most 13mm in diameter on the flange) with the spikes on both sides of the wheels' axle.

The model is available with or without couplers, for the version with couplers, I planned on using Marklin couplers of this type : https://www.maerklinshop.de/ersatzteile/33229/kupplung-5-st

but I haven't tested them yet.

You will also need 2 M2x6mm bolts and 2 M2 nuts, to attach the couplers

In order to make the carriage stable, I recommend using some kind of metal weight in the middle of the frame. There is a slot 40mm x 20mm x 6mm in the frame so that you can add a small metal plate in the middle.

All parts have to be glued together, some of the parts on the boom have aligning blocks to make sure the boom is aligned.

The crane is available in multiple boom positions, horizontal, slightly raised or fully raised as well as retracted, only the middle section extended, or both fully extended.

This model was designed with FDM printing in mind but you will have better results with an SLA printer especially for the small parts like the crane's hook. If printed on an FDM printer, you will need a 0.25mm nozzle (or finer) and layer heights of 0.05mm.

If you have any questions or want modifications done to the model, don't hesitate to send me an e-mail (s.marb.min@gmail.com).

Parámetros de impresión 3D

The name of the parts says how many times you should print each part, if there's a x2 it means you need to print it twice and if there's no indication it means you only need to print it once.

Some parts of the undercarriage, like the brakes are symmetrical across the undercarriage (from one corner to the opposite one), these should be printed twice but each identical pair goes across from one another. If you have trouble matching, feel free to reach out, I can send you more detailed pictures for their placement.

The cabin includes the lifting cylinder, to get the horizontal boom, print : CS1005_cabin_withHoryzontalBoom to get the boom to its max angle, print CS1005_cabin_withmaxAngleBoom and to get an in between angle (about 15°), print : CS1005_cabin_withMidAngleBoom

The boom is available in both an SLA optimised version and an FDM centric version, the one meant for SLA printers is in a single part.

For both versions of model, you will have to print the dragg chain, retracted for the version with the retracted boom or extended for either of the other versions. As well as all of the other small pieces of the boom (which are the same for all of the positions of the boom).

For SLA printers, use either CS1005_FullyextendedBoom_main_SLA (both extensions extended), CS1005_MidExtendedBoom_main_SLA (only the middle section extended) or CS1005_retractedBoom_SLA (both extensions retracted).

For FDM printers, you will have to print :

if the middle section is extended : CS1005_extendedBoom_main_FDM, CS1005_extendedBoom_BoomCylinderStickOut_FDM, CS1005_extendedBoom_MiddleSection_FDM and

CS1005_middleBoomSectionExtended_FDM

If the middle section is retracted :

CS1005_retractedBoom_middleSection, CS1005_retractedBoom_main

If the inner section is retracted : CS1005_retractedBoom_front_FDM

If the inner section is extended : CS1005_extendedBoom_InnerSection_FDM

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/ed76f1aa-86d4-45de-916b-2be05da1d3b0/CS_10_05_2025-Dec-06_04-50-06PM-000_CustomizedView39748245565.png)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/cf4e31e6-e353-409f-ab31-c7f04bf6bd60/MaterialHandler_0.png)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/a527fb4b-4631-4d6e-a9a5-650fa98bd028/Stacker_1.jpeg)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/7eda1024-8335-4851-b68c-91fc9eda8c7f/535C_picture_1.jpg)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/e689edc4-210b-4ea9-970b-dc5c0cd5cff9/G730_1.jpg)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/1ca58315-f804-449a-896e-822fe513947e/1641H_1.png)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/643b99c5-d682-4f96-acd5-dc9ddb6a5f27/1604ZW_2.png)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/1d86f77e-027f-4c78-ba60-bb1d2f0ea183/PresentationSAR1906.png)

/https://fbi.cults3d.com/uploaders/18722162/illustration-file/a07b9b86-0149-4ff7-a7b2-15f4c4b6cbac/CVB_1.png)