Descripción del modelo 3D

DISCLAIMER: Use at your own risk. The clearance between the aperture arm and the body of the S50 is very tight. Even making these parts as thin as I possibly could there is still a little contact with the base of the housing during a final movement of the arm in a downward position.

BACKGROUND: Although it is not technically a remix of thing https://www.thingiverse.com/thing:6518469, it did inspire me. I have printed that model and it is a great model so I felt the original designer should be credited. The dew shield with that model made me think of the horror stories of people having the arm of the S50 close with that dew shield in place and the grinding the motor made. That was the basis of the beginning of this design. I wanted to have a dew shield that would 'break away' without damaging the S50 if the arm did close due to power or plan completion.

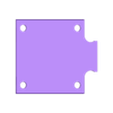

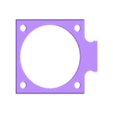

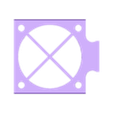

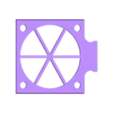

DESIGN CRITERIA: I decided I wanted to make a base that stayed in the S50 aperture and I wanted to be able to put the dew shield on as well as any masks. I also wanted to put a dust cover on that would stay in place when you shut the S50 down. As previously mentioned I wanted to be able to attach a dew shield to the S50 and have it break away without damage in the event of an arm closure. I settled on a slider type system with a base unit and slider panels. I made use of 5mmx1mm magnets to hold the sliders in place and in particular give a way to attach the dew shield.

The very limited clearance in the aperture arm forced me to make the parts very thin. The base is a total of 2mm thick with 1mm of that being the flange of the base. The sliders are 1mm thick and are flush with the highest part of the base that extends from the aperture. Even with them being this thin, there is a little rub at the end of the closing cycle for the S50 where the aperture arm drops downward enough for the inside edge of the base to rub against the base. I may do some more design work on this to overcome that.

Due to the thin nature of the parts I recommend printing in strong filament. I used black ABS in my case. PETG will probably be strong enough as well, but I am not sure PLA+/Pro/Tough will be and I am pretty confident regular PLA will just be too brittle.

PARTS NEEDED:

You will need 4 5mm x 1mm magnets for the base and each of the sliders.

You will need 4 5mm x 2mm magnets for the dew shield. You can probably stack a pair of 5mm x 1mm magnets but I had 5mm x 2mm magnets so I used them because I wanted the additional magnet power.

NOTE: You can probably just put the magnets in the mag base part (open circle slider) and the dew shield if you don't intend to use the dew shield with any of the other sliders. Once you start fighting with those 5x1's you might get annoyed with how difficult they are to work with. I broke more than one slider trying to get them in. I made the holes tight because they are friction fit in and are not glued. I experimented with heat setting them with a soldering iron but the heat actually demagnetizes the magnets and you will have to re-magnetize them if you do that. I think you can just let them sit in between to larger magnets for some amount of time to make that happen but I haven't messed with that yet since I had plenty of extra 5x1's. :)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/df359d33-11a4-43b7-8531-8258746046f2/Seestar_S50_Modular_Accessories_v1.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/1e2b1c92-edaa-4832-a4c4-e0d062e532bb/Cage_-_Empty.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/acb71d74-6017-40f0-9085-201a2a936a45/ccfb6121-2880-4319-a392-097a207a5368.png)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/b0e40980-67d4-4cfd-87a6-6aa5ee0cbe90/6e974eea-0ebd-4f3f-8d62-c67067dbb719.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/a7bd76d9-38bf-4044-8d40-e87010e51f25/94293267-a880-4547-b217-f3c867244575.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/5c1ccaa5-58e9-4025-b4bb-537d1f106b81/b16ffe6f-0bfe-4599-aaa3-7fcb47d56a83.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/8b7d6baf-cc54-49b5-97c5-62b769d87ba5/c299f002-daee-409d-b6ec-f75552072696.png)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/60ba6648-39f6-41b1-a5ce-cd99dd233ed5/Assembled.jpg)

/https://fbi.cults3d.com/uploaders/25296184/illustration-file/bc3e7909-6492-42ac-916b-c008b088cad5/D3_Dark-Dust_Cover_-_Front.jpg)