Wall-Mounted Drill Holder

Not long ago, I released a model of a wall-mounted magnetic holder for an electric screwdriver. It turned out to be so convenient in everyday use that I immediately decided to adapt it for another tool that had been sitting idle — a miniature drill.

Why idle? Simple: the tool wasn’t within reach. It lived in a box. And when something’s hidden away in a box — by the time you find it and open it, you’ve already forgotten what you needed it for. I’ve mentioned this before, by the way.

Design Features

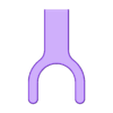

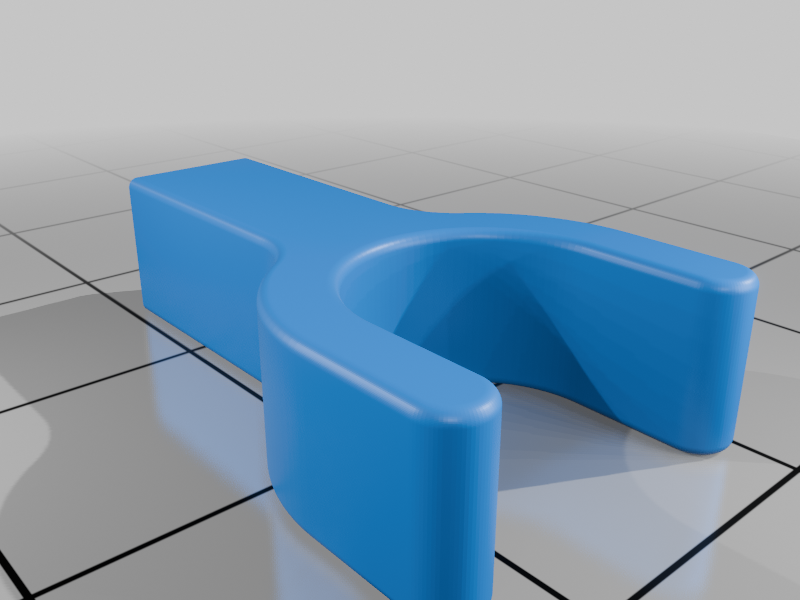

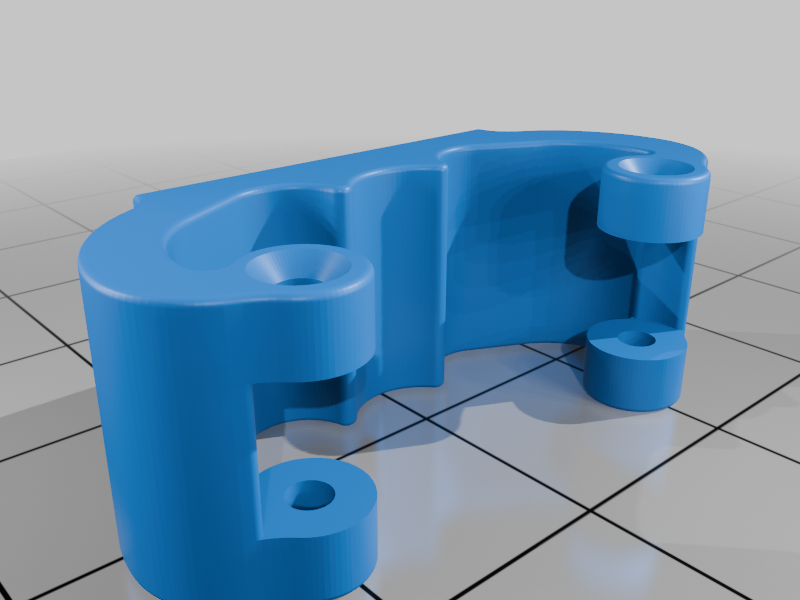

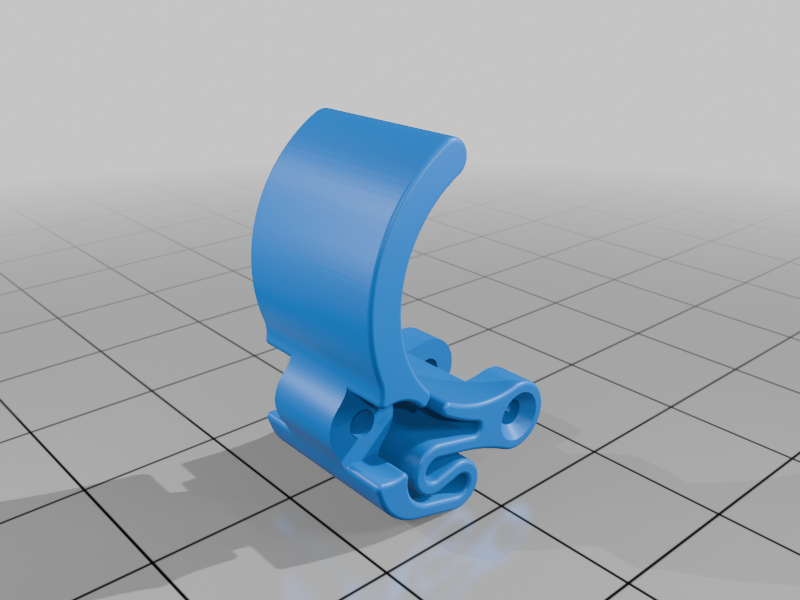

The holder model for the mini drill is structurally almost identical to the one I made for the screwdriver. The main difference is the shape of the top support: it’s not round but shaped to fit the mini drill’s body, which is closer to a rounded square and slightly smaller in diameter than the screwdriver.

The assembly process is exactly the same as I showed in the previous video. So there’s no point in filming a new video — it’s all the same steps.

Additional Elements

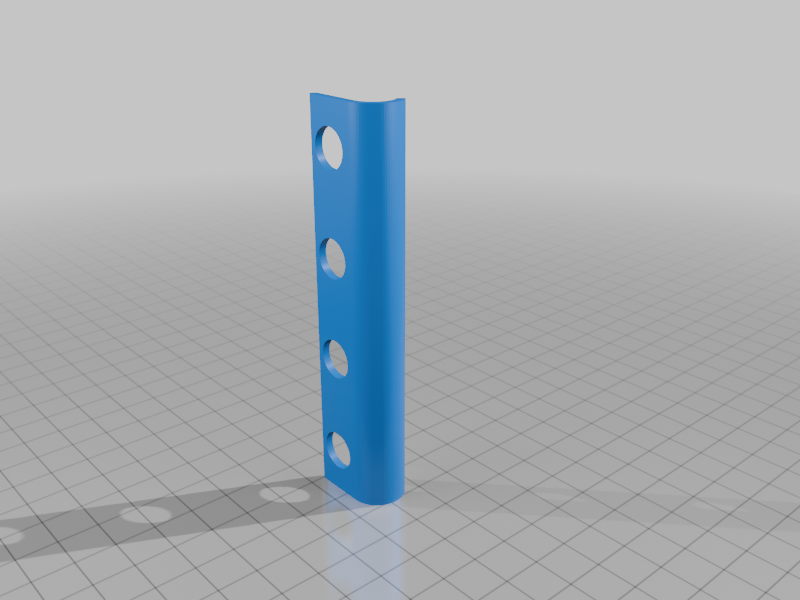

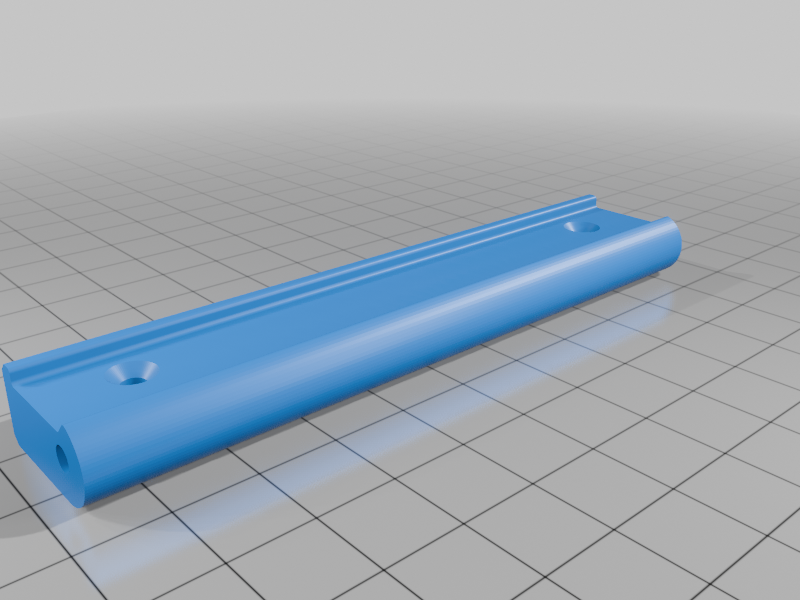

Included with the drill holder is an adapted version of the well-known FlipFlop dock — this time designed for storing drill bits specifically for the same mini drill. Like the main holder, it attaches to a metal wall using magnets and can snap into a vertical position when not in use.

Mini Drill Modification

The mini drill itself needed a small upgrade. I added a switch that completely disconnects the battery from the controller. This was necessary because the components operating in standby mode were drawing milliamps instead of microamps, as stated in the specs — which meant the battery would drain completely overnight.

Most likely, I just got a unit like that. Maybe it’s not a widespread issue, but I can’t say for sure — this isn’t statistical data, it’s just my personal case. I’ve seen components before that were supposed to consume almost nothing according to the datasheet but ended up pulling 40 mA in practice. It happens. A different production batch might not have this issue. I’m just sharing the observation.

In Use

First things first — this is not a drill for concrete. It’s tiny and not particularly powerful. But in its category, it’s absolutely irreplaceable. I often use it for drilling plastics, routing light pipes through enclosures, or widening holes for small screws. Basically, it’s like a precision mini-awl that’s always nice to have at hand.

The main mounting point is the SnapFlip clip that holds the drill in the center. The top and bottom supports are just guides. The FlipFlop dock for bits is magnetic, as described above.

Final Touches

At first glance, something like a wall-mounted holder might seem trivial. But it’s exactly these small decisions that change how you work: the tool doesn’t get buried and forgotten — it becomes part of your daily workflow. And that means it gets used more often.

That, in my opinion, is the key indicator of a good engineering solution — when an object simply integrates into your life without extra effort or reminders.

People often ask me in the comments: what printer did you use, what filament, what nozzle size, what settings? I try to answer this in advance by always including a 3MF-format file . It’s not just a model — it’s a fully prepared project for printing, complete with all of my settings, speeds, temperatures, layer height, and other details. This time, I printed everything using a 0.2 mm nozzle — partly because it delivers cleaner results, and partly because I honestly didn’t feel like swapping the nozzle. I had the time, so I just went with it and aimed for a clean print.

Parts links below:

Links to used tools:

My new machine:

My favorites:

Thank you for every tip or donation,

it means great recognition for me and helps a lot to keep going!

https://ko-fi.com/perinski

BTC:bc1qplpzq36ghw84hty4nn2zzu4ps4sdh4th0v93j8

ETH:0xc766ebbeAa76aaf629788c8F99C33A8d80d48977

My some other things:

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/4344bf8f-043f-432f-ab5e-6be03ea129b3/Wall-Mounted-Drill-Holder.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/2bb766e0-1230-497f-b396-04868e9e508d/f3ccdd27d2000e3f9255a7e3e2c48800_display_large.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/5eb723d9-f2bf-4c55-a5d1-1a90c44b56ab/f3ccdd27d2000e3f9255a7e3e2c48800_display_large.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/93da2140-6023-46d0-abba-87feb33918ec/Sanding-Tool-2.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/0544955d-8ffd-4cdc-9a43-5ba09fb37ee8/Knob-Bolt-M6.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/194fcbc1-c0ad-4755-b5bf-c9bbf0dff215/Filament-Clip.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/ac65a85e-dd55-417b-957c-d683a4d205e2/GT2.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/e29f4f54-d0d0-4e67-a00c-181893ada23c/Knob-Bolt-Hex-Head.jpg)

/https://fbi.cults3d.com/uploaders/13528167/illustration-file/64d97d47-3ad4-417c-8c57-c3609f7e085c/Christmas_tree.jpg)